Types of industrial lighting and its norms

Lighting of industrial enterprises must comply with a number of standards. For each industry, they are different, as working conditions change depending on the work performed by a person. The requirements for industrial lighting are much stricter than for domestic lighting, and any violations lead to fines or even a ban on work until the problems are fixed.

Features of industrial lighting

It is worth analyzing the features of lighting in production in order to understand its differences from other types and to know the requirements that must be observed. The main varieties are:

- natural. The most preferred option, giving good light transmission and comfortable for the eyes. In such conditions, the eyes are the least tired, but it is problematic to provide good natural light for all workers, the installation of large windows or the construction of skylights is required.So called elements with two rows of windows to improve illumination.Natural lighting is best for all types of production work.

- Artificial. It is applied everywhere where it is not possible to provide natural light. It is implemented in different ways, since there are many light sources and each has its own characteristics that determine the scope of application. When using artificial lighting, the standards established for a particular production area are taken into account. The energy consumption must not be overlooked, as choosing energy-saving lamps you can save.

- Combined or mixed. It is used most often, as it provides the desired level of illumination and at the same time saves electricity. It happens that most of the day you can use natural light, and turn on artificial light at dusk, as well as on days with heavy cloud cover. Here it is necessary to make a system with adjustable intensity of artificial lighting, since it can also work as the main one, which will require an increase in brightness.

The main requirement when planning and choosing industrial lighting is practicality, appearance does not really matter.

General information

All types of lighting in production must comply with a number of general requirements that are unchanged. This simplifies the selection and provides clear guidelines to select those solutions that will provide the desired indicators:

- The level of illumination is determined depending on the requirements for a particular production. It makes no sense to list the exact data, since the list is very large, all the information of interest can be found in GOST R 55710-2013, GOST R 56852-2016, SNiP 23-05-95 and SP 52.13330.2011.Additional requirements that are in the industry documentation may be used, their observance is also mandatory.To ensure optimal working conditions, a number of norms must be observed.

- For a number of production works, an increase in the norm of illumination by 1 step is required. This applies to the food industry and enterprises where it is important to ensure clear visibility and color reproduction. It may be necessary to improve the lighting in factories where you need to strain your eyes for most of the working time. Another option is if the age of most of the employees in the room exceeds 40 years.

- The quality of lighting should be constant throughout the working time. It is important to ensure constant performance, so depending on the time of day and the weather outside, there should be different modes of using lamps. If they constantly work the same way, energy costs will increase significantly. This factor depends on natural lighting, without it there is no point in adjusting artificial light.

- All safety standards established for a particular area of production must be observed. It all depends on what equipment is installed, whether there is a danger of damage to lines, etc. This aspect is usually controlled by the specialists of the safety department, they also set the necessary standards.

- The use and adjustment of luminaires should not cause difficulties for employees. Switches are placed in easily accessible places so that you can quickly turn off the electricity supply. It is necessary to provide for a supply of replacement lamps so that if the light element fails, it can be quickly replaced and ensure normal working conditions.Service shouldn't be a problem.

- If high-quality lighting is required in the workplace, additional lights are used to highlight a table or other object. Either stationary lamps or adjustable ceiling lamps are used, which is much more convenient if you need to periodically shift light accents.

It is impossible to violate the norms both in the direction of decrease and in the direction of excess. High brightness can cause eye strain and premature fatigue.

Types of lighting used in the workshops of enterprises

It all depends on the type of lighting. Several categories can be distinguished. Each has its own characteristics that must be taken into account when planning and installing equipment.

natural

Such lighting in the workshop or on the production site is most preferable. It will give a clear color reproduction, will allow you to work with minimal eye strain. Suitable for small buildings, the best quality of light is provided if the windows are located on the south side. At the same time, it is important to use blinds on the windows in order to adjust the brightness of the lighting if necessary, especially during periods when the sun shines directly into the windows. The main types are:

- Side one-way lighting is the most common. This option is suitable for most buildings, the level of illumination depends on the size of the windows, they are often made to the entire wall. But here we must take into account that the larger the openings, the higher the heat loss in winter, which increases the cost of heating.The more windows, the better the natural light.

- The option of placing windows on both sides is suitable for large rooms where one-sided light is not enough or it is possible to provide natural light from opposite and adjacent walls.

- Overhead lighting is equipped with openings in the roof or a special design, which is called a lantern. This solution is less common due to the complexity of the arrangement and the high costs of installing windows or upgrading the roof. It is well suited for small buildings and large production modules with an area of several thousand square meters (in this case, a lantern is most often made along the entire building).In many modern workshops, ceiling openings occupy a large part of the surface.

- The combined version combines top as well as side light, so in certain conditions it can provide a good result. Often used for buildings of large width, where the light from the windows almost does not enter the center. Designs are different, almost always they are developed individually, taking into account the lighting standards and the features of the production process.

By the way! Natural light can be either direct or reflected. The second option is much more difficult, as it requires the use of a reflector system that will provide uniform diffused illumination.

To improve performance, it is necessary not only to think over the location and area of windows, but also choose the right color for walls and other surfaces. The lighter they are, the greater the reflection coefficient, which is very important.

artificial

The norms of illumination of industrial premises are set mainly for this option.With its help, it is easy to achieve any result, since there is no need to enlarge the windows, it is enough to install additional lamps or arrange them correctly. Main varieties:

- Working lighting is the main type, which should provide optimal conditions for employees to perform their duties. It is also necessary for the comfortable movement of people and the passage of vehicles indoors. Used during business hours, can be both general and local. For special lighting conditions, additional lamps with brightness control are used.

- Safety lighting is essential for industries where shutting down work can be dangerous or when there is a power outage, it takes time to turn off the equipment. Allows you to continue working if there are power outages. Most often used at pumping stations, communication centers, boiler rooms, sewer communications, etc.

- evacuation the lighting turns on when there is a power outage and helps employees safely leave the building. Most often it is used in workshops with equipment, where movement without light can create a danger. It is also mandatory to make emergency lighting in rooms without natural light, on landings, if the height of the building is more than 6 floors, or if more than 50 people can be there at the same time. It is necessary to put this option in rooms in which more than 100 employees work.Evacuation lighting should ensure the safe evacuation of workers if necessary.

- Security lighting is necessary during non-working hours and will provide good visibility both in the corridors and passages of the building, and along the perimeter of the territory and along the facades of buildings. It can work continuously at 10% of full power or turn on when a motion sensor or other security system is triggered. It happens both separately and combined with other options.Security lighting should provide the required level of facility security.

- duty light usually included after hours if there are employees performing duties on night shifts. It is needed to ensure visibility in the aisles, corridors, stairwells and other places where people are only occasionally. The main purpose is to ensure minimum visibility, no norms have been established in this regard.An example of emergency lighting with main LED lights set to 5% power.

Depending on the characteristics of the distribution of artificial light, it can be divided into the following types:

- General lighting is located under the roof of the room, it should provide a comfortable background and be distributed evenly. Usually, specific norms are determined by SanPin, which sets indicators for different industries. The location is selected individually and depends on the type of lamps and their power.If general lighting is sufficient, there is no point in using additional lighting.

- Local lighting is used for certain areas or areas that require better light. With it, you can adjust the indicators where necessary.Local lighting highlights the workspace.

- Combined solutions allow you to combine different options or modes to use them when necessary.Modern systems can have a different configuration, which allows you to provide any lighting mode.

It is best to normalize the system in advance and coordinate it with the supervisory authorities in order to avoid problems.

Combined lighting

This variety combines natural and artificial light and allows you to achieve optimal performance with minimal energy consumption. Most often, the conditions are uneven during the day or season, since the illumination indicators depend on many factors - cloudiness, sunrise and sunset times. Natural light is planned taking into account the fact that it may not provide the desired performance.

Lamps and fixtures are located in the same way as without natural light, since most often you need to work during periods when there is no sun. It is important to provide several modes in order to adjust the equipment depending on external conditions.

If tall buildings are located nearby or large trees with a dense crown grow, then the natural light indicators will be lower at times. It is better not to plant anything nearby.

Requirements and norms

All standards can be clarified in SNiP 23-05-95, if the enterprise is equipped according to European standards, EN 12464-1 can be used. There are many indicators, they may vary depending on the industry, but the main ones are:

- Illumination. It is measured in lux and is calculated based on the amount of light per square meter of area. For standard production shops, an indicator of 200 lux is sufficient, while for high-precision production, norms can reach 5000 lux.In this case, it is important to take into account the coefficient of natural light and contrast - there should not be a strong difference between the working area and the surrounding space. In critical areas, a number of additional criteria are also taken into account.

- Colorful temperature shows the brightness, the creation of a comfortable microclimate and the provision of the desired level of concentration depend on it. If natural color reproduction is most important, then it is worth choosing options with temperatures from 5500 to 6000 K (kelvins). Luminaires with a warm spectrum create a calm environment, but can adversely affect performance. Cold light stimulates improved work performance, while constantly being in a brightly lit room can provoke stress.Color temperature and scope.

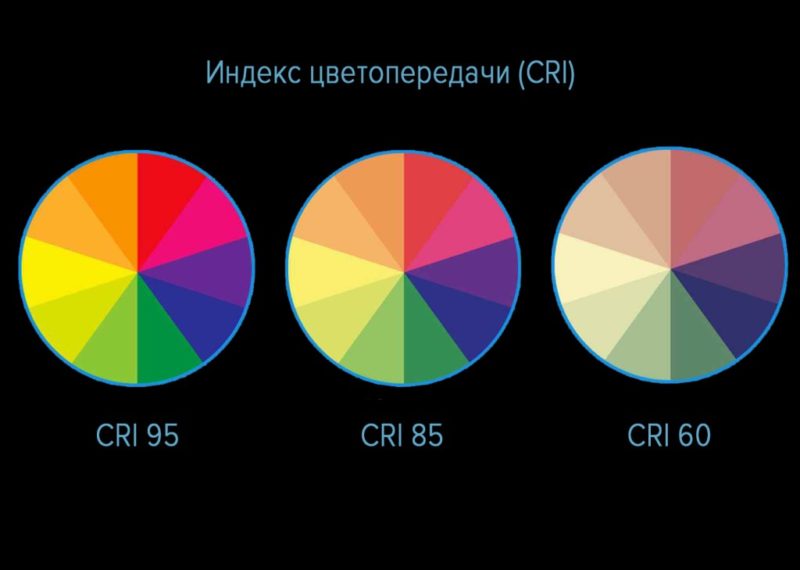

- Color rendering index taken into account where it is necessary to ensure natural color reproduction. Average values (measured in Ra) for most industries range from 50 to 60. At the same time, industry standards may have other values, much higher. The maximum value is 100 and corresponds to natural light.CRI Example

- flicker Light is measured in Hertz. If the indicator is less than 300 Hz, then a person’s vision perceives a change in intensity, such conditions create discomfort and vision gets tired faster. Therefore, when choosing fixtures, you need to pay attention to this indicator. Led lamps give the least flicker, which ensured their popularity.Pencil test in the presence of a flickering lamp.

- Blindness indicators say that discomfort is created for vision due to direct or reflected radiation. This effect is observed in places where high precision is required.

- The uniformity of illumination shows what differences there are depending on the position. The more accurate the production, the higher the requirements for this indicator. Usually the exact figures are established by industry documents, as they vary greatly in different areas.

- Energy efficiency of using electricity for lighting. If in incandescent lamps most of the energy is spent on heat radiation, which increases the cost of light, then in modern models the figures are much higher.

Illuminance indicators are measured in strictly defined places. For large-scale productions without special requirements for the quality of light, this is done in the place farthest from the windows, a meter from the wall on the floor, or approximately in the middle if the windows are on both sides. For high-precision operations, the value must be measured at the level of the working surface.

Type of light bulbs, shape and size of fixtures

It is necessary to choose the type of lamps, there are several types, each with its own characteristics that should be taken into account:

- Incandescent lamps work by heating a tungsten filament. Because of this, electricity is spent inefficiently, most of it is spent on heating and thermal radiation. At the same time, the brightness of the light elements is the lowest of all, and the life of only 1000 hours. They give yellow light, which will not provide a comfortable environment for high precision work.

- Halogen lamps - an improved version with a filament and gas pumped into the flask. They have twice the life and the quality of light is higher, but it is better not to use this solution due to the strong surface heating and unnecessary power consumption.

- Fluorescent products shine brightly, but do not provide good light transmission. During operation, the lamps flicker, which provokes visual fatigue during long work. Another disadvantage is the mercury vapor inside the flask, if damaged, they pose a danger to humans and the environment. Fluorescent light is not suitable for workshops with rotating mechanisms, as it provokes a stroboscopic effect.

- LED lamps give even light of any brightness, it can be adjusted using a dimmer. The diodes do not flicker, so the eyesight is less tired, the service life is 50,000 hours, which is many times longer than any other option. For long work it is necessary to install reliable voltage stabilization blocks.LED lighting allows you to provide excellent quality of light with low energy costs.

- Sodium lamps 4 times better than LED in terms of efficiency, but more suitable for the street and warehouses, since the light is yellow and the color rendering is low.

It is not forbidden to use different lamps if they give a good effect.

Luminaires must be selected for the room and take into account how they will be used, there are a few tips to remember:

- For general lighting of a large workshop or production area, it is better to take rectangular or square models. Power and location is selected according to the requirements that must be met. You can mount it on the ceiling and on cables if the ceiling is high.

- To highlight a small work area, use round or oval shades that can be adjusted. You can put narrow and long LED models that can well illuminate a table or other space.

In conclusion, a video lecture on the topic: Industrial lighting.

When choosing industrial lighting, it is necessary to study the requirements of GOST, SNiP and industry documents. Based on them, make a calculation of the number and type of fixtures and a project indicating their location.