Description and principle of operation of the light bulb

What is an incandescent lamp

An incandescent lamp, hereinafter referred to as LN, is a source of artificial light, in which the luminous flux is obtained by heating a thin metal filament to the temperature of the glow of a red-hot metal. For heating, an electric current is passed through the filament. The first lamps had a filament of charred organic matter, such as bamboo, in the form of a fiber.

To prevent the thread from burning out quickly, air was pumped out of the flask and sealed. Or they filled the flask with a gas composition in which there is no oxidizing agent - oxygen. Such gases are called inert - argon, neon, helium, nitrogen, etc. These gases are named so because they do not react with metals, i.e. inert.

First lamps with a carbon filament had a working resource of no more than a dozen hours. It was significantly increased after the replacement of carbon filament with thin metal wire.

Such a light was called incandescent light, i.e. hot metal light. And the thread was called the filament. For example, steel heated to 1200°C glows yellow-white, while at 1300°C it glows almost white.

At the end of the 19th century, the carbon thread, which quickly burned out, was replaced by refractory metals - tungsten, molybdenum, osmium or metal oxides - zirconium, magnesium, yttrium, etc.

By filling the flask with inert gases, the rate of evaporation of the metal from the hot filament was reduced, and, therefore, the duration of its operation was increased.

At high power, the filaments are made in a "branched" form. Projection light sources for creating a directional flow have a thread of complex configuration, forming a flat structure perpendicular to the radiation axis. In this case, a light reflector is placed inside the bulb, for example, in the form of a thin layer of sprayed metal - silver or aluminum.

To power the lamp directly from the mains that existed at that time, which had a constant voltage of 110 V, a long and thin metal thread was needed. This provided increased resistance, which means that less current was required for heating.

For a dense “packing” in a small volume of a transparent glass flask, the thread was repeatedly bent and placed on wire holders.

Such bending of the thread complicated the design of the first light sources, which worked much longer than the "coal" ones. A breakthrough in the design of incandescent light bulbs was the proposal to twist the thread into a spiral. This reduced its size by several times.

An even smaller size of the incandescent body was obtained by folding a thin spiral into a second spiral, but of a larger diameter. The double helix is called the bi-helix.

The next stage in the development of light sources was the transition to AC networks and the use of a transformer to reduce the supply voltage of the lamps.

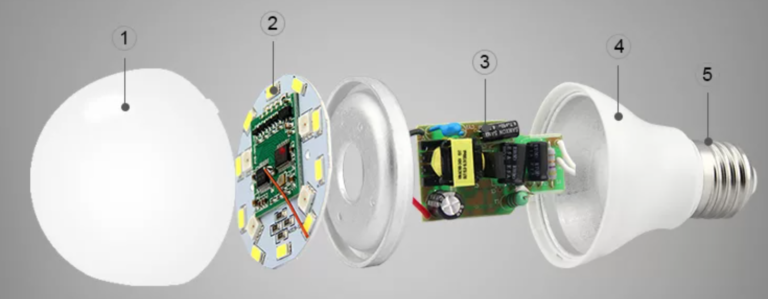

The main parts of an incandescent lamp

The main structural elements of an incandescent lamp include:

- filament or filament body;

- fittings for fastening the thread;

- a flask to protect the thread from rapid combustion and external influences;

- base for installation in a cartridge and connection to the mains;

- socle contacts - a threaded body and a central contact in the bottom of the socle.

The armature is designed to fasten the thread and create the required configuration and direction of the light flux.

The base is needed for fixing in the mounting cartridge and connecting to the flask. In retrofit lamps, analogues of incandescent lamps, a part of the power device is placed in the base.

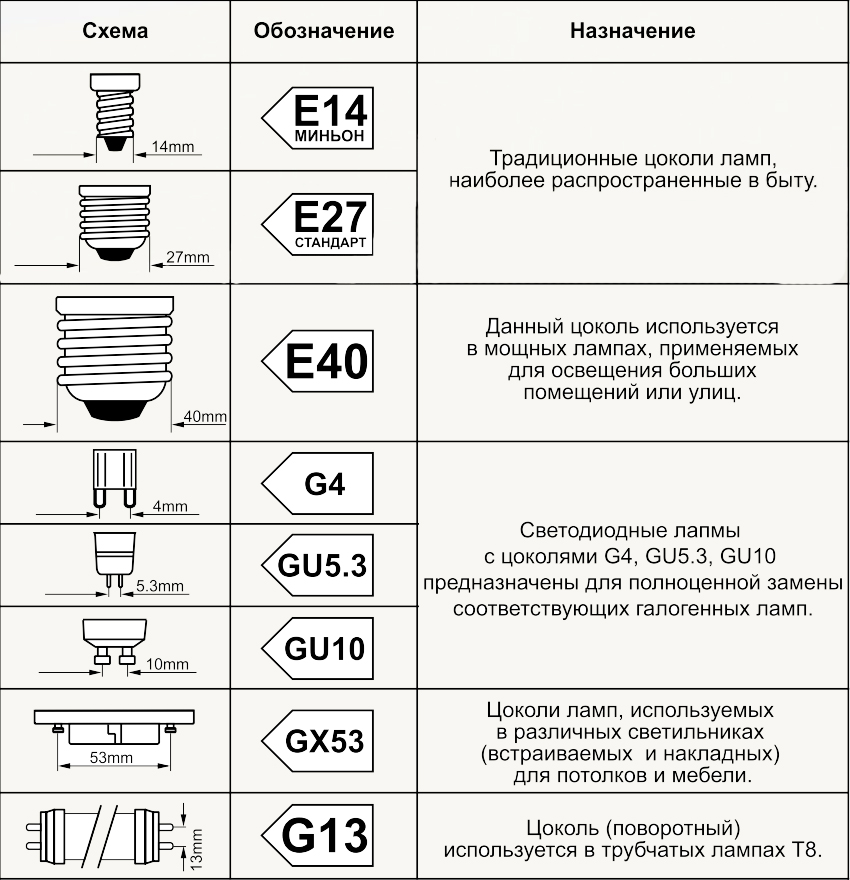

plinth

On the halogen incandescent lamps, depending on the supply voltage, power and design of the flask, several types of socles are installed - threaded, pin, bayonet, pin, etc.

The system of contacts on the socles is needed to connect to the mains or power supply.

Flask

Transparent flask LN is used for:

- protection of the thread from the external atmosphere containing an oxidizing agent - oxygen;

- creating and maintaining a vacuum or gas composition;

- placing a phosphor and/or coatings that convert different types of electromagnetic energy into visible radiation, returning heat to the filament, converting invisible UV and IR radiation into light, correcting the hue of the lamp glow - red, green, blue.

Incandescent body

The incandescent body is a thread rolled into a spiral or bi-spiral or a thin metal ribbon.

Gas medium

Inert gases that fill the bulb of a lamp, for example, nitrogen, argon, neon, helium. In a mixture of inert gases, halogen substances are added.

How LN works and how it works

The device of the incandescent light bulb has changed little during its development. The main element operating on the principle of the glow of an incandescent substance is a filament or an incandescent body. This is a thin tungsten wire with a diameter of 30-40, maximum 50 microns or micrometers (millionths of a meter).

Incandescent colors start from red and as the temperature increases, they pass through orange, yellow to white. With a further increase in temperature, the metal of the incandescent body first melts, and then, in the presence of oxygen, burns.

Video Tutorial: How Modern Light Bulbs Work

Cold tungsten filament has low resistivity. Tungsten, like most metals, has a positive temperature coefficient of resistance TCR.This means that in the process of heating the filament with an electric current, its resistance increases.

Before the lamp is turned on, the filament is cold and has little resistance. Therefore, at the moment of switching on, a current is supplied 10-15 times more than the nominal one. This jump is called starting. And often he is burnout cause incandescent bodies.

It takes a fraction of a second to warm up the thread. During this time, its resistance increases. Initially, a large current passing through the lamp, as the gas, bulb and all structural elements warm up, decreases to the nominal value. So the light source enters the specified mode and produces a passport luminous flux. The hue of the glow also becomes nominal, i.e. corresponding to a color temperature from 2000 to 3500 K. It is called warm white and has several gradations of color temperature with original names and abbreviations in the specified range. For example:

- super-warm white - 2200-2400 K, denoted S-Warm or S-W, it is also very warm white or Warm 2400;

- warm - 2600-2800 K or Warm 2700;

- warm white - 2700-3500 K or Warm White (WW);

- another warm one is 2900-3100 K or Warm 3000 (W).

Temperature of individual lamp elements

The outer surface of the LON bulb depends on the power of the lamp and can be heated up to 250-300℃ or more.

The thread heats up to 2000-2800℃, at the melting point of tungsten 3410°C.

In some designs, the filament is made of osmium with a melting point of 3045 ℃ or rhenium - 2174. So the emission spectrum of the LN is shifted to the red zone of the visible spectrum.

What gas is in the bulb

In the first lamps, the air was pumped out of the flask.Now only low-power light bulbs, no more than 25 watts, are evacuated (air is pumped out).

During the operation of a tungsten wire heated to 2-3 thousand degrees, metal intensively evaporates from its surface. Its vapors settle on the inside of the bulb and reduce its light transmission.

Studies conducted at the beginning of the last century showed that if the flask is filled with an inert gas, the evaporation will decrease and the light output will increase. Therefore, the flasks began to be filled with one of the inert gases or their mixture. Most often, these are argon, nitrogen, xenon, krypton, helium, etc. Helium is used for effective passive cooling of the internal elements of a new type of LED retrofit lamps.

This experiment is strictly not recommended to be carried out at home.

Their main light-emitting element is a thin rod made of artificial sapphire or glass, on which LED crystals are located. Such an emitter is called a filament. Some "experts" confused the essence filament lamps and called them "lamps with sapphire light emitters". Although artificial sapphire in these lamps is used only as a mounting base and passive heat sink for LED crystals.

The failure of the LN in most cases is associated not with the evaporation of the metal from the surface of the incandescent body, but with the acceleration of this process in the zones of violation of the filament thickness. This occurs in the zone of a sharp inflection of the wire or its fracture. In this place, its resistance locally increases, the voltage, power dissipation and metal temperature increase. Evaporation accelerates, becomes an avalanche, the thread quickly reduces its thickness and burns out.

This problem was solved in the late 1950s and early 1960s by starting the mass production of halogen incandescent lamps.

Halogens - chlorine, bromine, fluorine or iodine - began to be introduced into the composition of an inert gas or mixture. As a result, the process of metal evaporation stops completely or slows down significantly. The atoms of these additives bind tungsten vapor, forming molecules of unstable compounds. They settle on the surface of the incandescent body. Under the action of high temperature, the molecules decompose and release halogen atoms and pure metal, which settles on the hot surface of the thread and partially restores the evaporated layer.

This process is intensified by increasing the pressure. This increases the filament temperature, service life, light output, efficiency and other characteristics. The emission spectrum shifts to the white side. In gas-filled lamps, the darkening of the surface of the bulb from the inside from tungsten vapor slows down. Such light sources are called halogen.

Electrical parameters

The electrical characteristics of incandescent lamps include:

- electrical power, measured in watts - W, the range of manufactured models - from several watts (light bulb for a flashlight - 1 W) to 500 and even 1000 W;

- luminous flux, Lm (lumen), is related to power - from 20 Lm at 5 W to 2500 Lm at 200 W, with higher power, the light flux is higher;

- luminous efficiency, energy efficiency or efficiency, Lm / W - how many lumens of light in the form of a luminous flux gives each watt of power consumed from the network or from a power source;

- luminous intensity or brightness, cd (candela);

- color temperature - the temperature of a conditional black body that emits light with a certain shade.

The purpose of the electric lamp

Electric lamps can be divided into several types according to their application - for public, technical and special use.

The main public use is to provide any person, animals and birds with artificial light at night or in a dark place in a room.

Using light, people prolong their daily activity for several hours. It can be work and study processes, household chores. Road safety is improving, the ability to provide medical assistance in the evening and at night, and many others.

Lamps are actively used on livestock farms and poultry farms, for growing plants in greenhouse complexes. They are illuminated with light of a certain spectrum and the magnitude of the luminous flux. For breeding fish, light with a special spectral composition is also needed.

technical purpose. In production, for technological purposes, devices are used that give visible and invisible light. Examples:

- for accurate and important work, a person needs a high level of illumination of the workplace;

- IR - infrared radiation is used in industry, for example, for non-contact heating of structural parts or in climate technology for heating a person working in open frosty air, in military equipment and hunting - night sights for weapons, night vision devices, etc.;

- UV- radiation is used in dentistry for fast hardening of fillings, in the manufacture of dentures, etc., in medicine and sanitation - for disinfection of premises, tools, clothing, furniture surfaces, air, water, medicines, etc.

Special-purpose lamps are used in outdoor and indoor illuminated advertising, criminalistics, aviation and astronautics, light accompaniment of show performances, and many others.

Main types and characteristics

The main types of incandescent lamps are:

- General purpose lamps. Designated by the abbreviation LON. Usually these are devices with a power of 25, 40, 60, 75 and 100 watts. The most common - 60 watts. But industrially produced LON with a capacity of 150, 200, 500 and even 1000 watts.

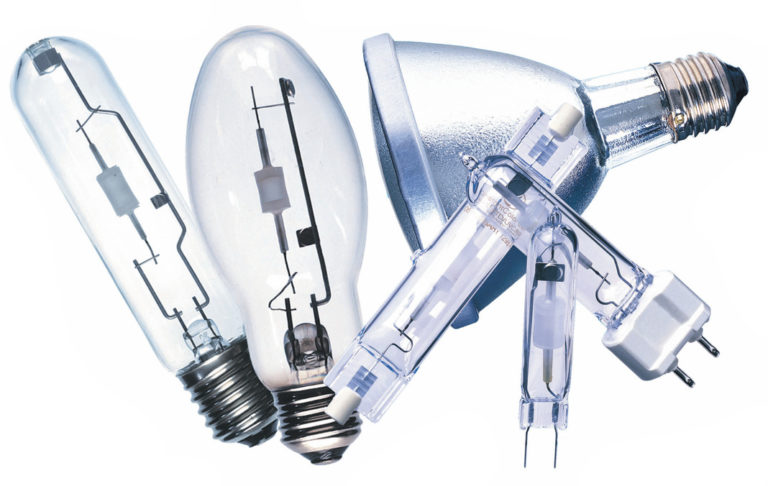

- Halogen incandescent lamps. Produced for operation from a high-voltage network of 220 or 110 V and from a low-voltage network. In this case, they are powered by a step-down transformer.

Varieties of low-voltage halogen LN:

- capsule, have the form of all-glass tubes with different socles - end pin GY6.35 or G4;

- reflex, having a reflective element, with a diameter of 35 to 111 mm, GZ10 base with options.

High voltage. Main voltage 220-230 V, 50 Hz. These lamps have more options:

- linear in the form of a glass tube with R7S socles;

- cylindrical - socles E27, E14 or B15D;

- with a remote or additional flask.

In the latest model, a small-sized halogen lamp-capsule or tube is rigidly mounted inside the lamp. It is welded to the central rod of a conventional LON bulb, has flexible leads connected to a standard Edison E27 or E14 base. With a power consumption of 70-100 W, it provides a luminous flux of 20-30% more than a conventional incandescent lamp.

These models have a higher energy efficiency, reaching 12-25 lm / W, while conventional LONs have a light output from 3-4 to 10-12 lm / W.

The service life of halogen models ranges from 4-5 to 10-12 thousand hours.

Separation of lamps by purpose and design

decorative lamps

In recent years, retro lamps have appeared that imitate vintage Edison LNs.

In addition, they imitate a “candle”, “candle in the wind”, “bump”, “pear”, “ball”, etc. in the shape of a bulb.

Mirrored

Mirror lamps have a part of the bulb covered from the inside with a reflective layer. Most often, this is a coating of metal - silver, aluminum, gold, etc. This layer can be thin, translucent or thick, opaque.

Mirror structures are used in production for absolutely clean process heating, for example, in semiconductor production with the highest purity of materials. In this case, the disadvantage of incandescent lamps - a large flux of infrared radiation - becomes their unsurpassed advantage.

Such lamps are used in lamps with a narrow rotary beam of light.

Signal

Signal lamps are flashing light sources. Usually in the form of flashing beacons, for example, on official cars, on airplanes and helicopters, for transmitting light messages in the fleet, etc. They have a thin filament that provides a quick set of brightness.

Transport

This type of lamp is designed for use on different types of transport - cars, railways and subways, river and sea vessels. The main requirement for them is resistance to vibrations and shocks. To do this, the filament is made short and mounted on a plurality of supporting elements.The bases of such lamps are bayonet Swan, pin or soffit. They do not allow the device to get out and fall out of the cartridge.

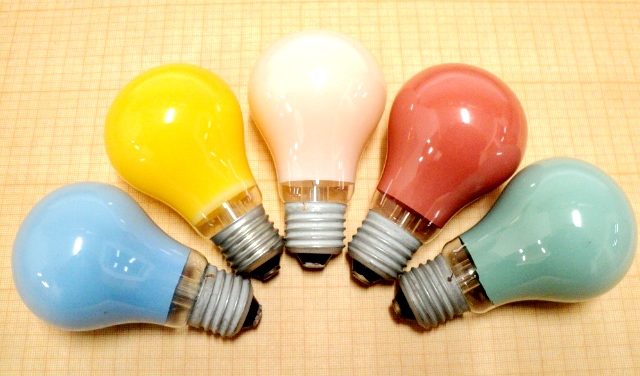

Illuminations

From the name it is clear that the lamps are used for illumination. Therefore, their flasks are made of glass of different colors - blue, green, yellow, red, etc.

double strand

The scheme of such an incandescent lamp: in one bulb there are two separate incandescent filaments. For example, in a car headlight, a two-filament lamp is used like this:

- when voltage is applied to one thread, the dipped beam is turned on - the light flux is “pressed” to the roadbed and the beam extends over several tens of meters;

- after switching to the second thread, the light rises and its range can reach hundreds of meters, and the flux will be much greater.

Such lamps can be in the rear light. The first thread is for side lights, the second is for a brake light.

In traffic lights, double-filament lamps increase their reliability. Duplication allows the device to work either with one thread, or turn on a second one after the first has burned out. And, for example, on railways, the reliability of signaling is a guarantee of transportation safety.

General, local purpose

Top row, from left to right - a lamp with an E14 base - for chandeliers, sconces and small-sized lamps; with E27 base - general purpose; green, red, yellow - illuminating.

Bottom row: blue - medical purpose for procedures; a mirror with a reflector - for photographic works or special lighting, with violet glass, two outer ones - decorative with a “candle” bulb and E27 and E14 socles.

Pros and cons

Advantages of incandescent lamps:

- low price - simple and inexpensive materials, design and technology have been worked out for decades, mass automated production;

- relatively small size;

- voltage surges in the network do not cause an immediate failure;

- start-up, as well as restart - instant;

- when powered by alternating current with a frequency of 50-60 Hz, the brightness pulsations are hardly noticeable;

- the brightness of the glow is regulated by dimmers;

- the radiation spectrum is continuous and familiar to the eye - similar to the sun;

- almost complete repeatability of lamp characteristics from different manufacturers;

- color rendering index Ra or CRI - the quality of reproduction of color shades of illuminated objects - is 100, which is fully consistent with the sun indicator;

- the small dimensions of the compact filament give clear shadows;

- high reliability in conditions of severe frost and heat;

- the design allows mass production of models with operating voltages from fractions to hundreds of volts;

- power supply from alternating or direct voltage in the absence of start-up devices;

- the active nature of the resistance of the filament provides a power factor (cosine φ) equal to 1;

- indifferent to radiation, electromagnetic impulse, interference;

- there is practically no UV component in the radiation;

- regular work with frequent switching on/off of light and many others is provided.

The disadvantages include:

- nominal service life of LON - 1000 hours, for halogen incandescent lamps - from 3 to 5-6 thousand, for luminescent - up to 10-50 thousand, for LED - 30-150 thousand hours or more;

- the glass of the bulb and the thin filament are sensitive to shocks, and during vibration, resonances are possible at some frequencies;

- high dependence of energy efficiency and service life on the supply voltage;

- The efficiency of converting electricity into visible light does not exceed 3-4%, but increases with increasing power;

- the surface temperature of the flask depends on the power and is: for 100 W - 290 ° C, for 200 W - 330 ° C, 25 W - 100 ° C;

- when turned on, the current surge before the filament warms up can be ten times higher than the nominal value;

- lampholders and fittings of fixtures must be heat-resistant.

How to increase lamp life

There are many ways to increase the service life. Most used:

- limiting the starting current by turning on a thermistor in series with the lamp, the high resistance of which decreases as it is heated by the starting current;

- soft start with manual brightness control by thyristor or triac dimmer;

- lamp power through a powerful rectifier diode, i.e. rectified voltage halves of the sinusoid;

- series connection of lamps in pairs in multi-lamp fixtures, for example, in chandeliers.

Modern industry produces a large number of different types of incandescent lamps with a wide range of operating voltages and powers, with different shades of glow, configurations of bulbs and socles. This range allows choose the right lamp for any use.