Ways to test the LED strip for performance

[ads-quote-center cite='Mikhail Afanasyevich Bulgakov']

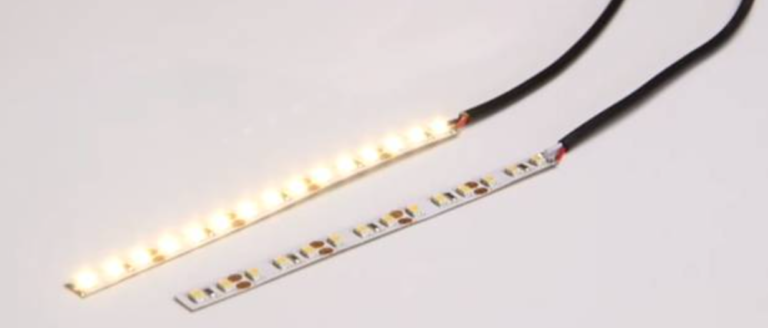

In recent years, the popularity of LED strips just rolls over. You can meet them everywhere. They are used for lighting and decorative purposes. It is not difficult to buy a tape and a power supply. Everyone can check and troubleshoot, but we will now find out how to do this and what is needed.

Malfunctions and their check

The most common tapes are powered by a mains voltage of 12 volts, it is safe for humans. So, to check the LED strip, we need: a strip, a power supply for it, a tester and a little time.

Power Supply

“First you need to find the beginning”

Checking any circuit is carried out in stages.It is recommended to start with the power supply, as it primarily affects performance. There are two types of power supplies:

- closed type - have four wires, two of them are an input, this is an AC power source from a 220 V network, and an output, also two wires. In the photo example, according to the connection diagram, it can be seen that a 220 V AC network is connected on the left, and a 12 V DC output is connected on the right, indicating the polarity according to the color. Brown (brown) is +, Blue (blue) is minus. Observe polarity!

2. open type – connection is made with clamps. Such power supplies are similarly labeled. In our case, pins 1 and 2 are 220 V AC, pin 3 is ground, 4 and 5 are minus, 6 and 7 are plus.

To check the power, set the tester to measure AC voltage, make sure that 220 V is supplied (terminals 1 and 2), then switch to DC measurement mode and make sure that the output (terminals 4 and 6) receives the required 12 V.

Please note that a power supply failure most often threatens to replace it, since repairs can be much more expensive.

After checking the health of the power supply, we proceed to the next step - check the LED strip with a multimeter.

Ribbon Test

There are four types of possible faults:

- does not burn completely;

- half does not burn;

- the entire tape flashes or flickers;

- flashes or flickers or does not light a separate part (parts);

Above, we examined what malfunctions can be, then we will consider them in detail.

Not fully lit

After checking the power supply, check the wires: they may be damaged, and the voltage to tape does not arrive. Check the quality of the connection of the wire with the tape, it can be done:

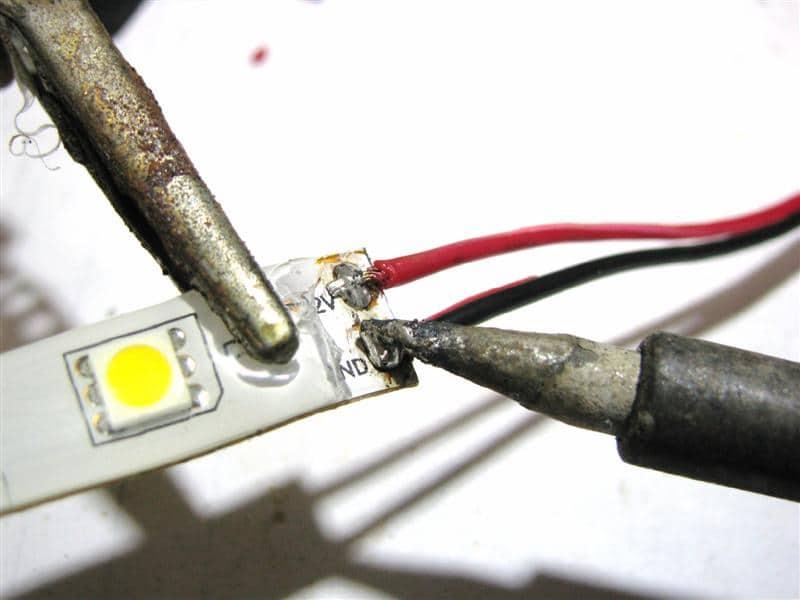

- With help rations and may also be damaged.Photo 05. Soldering the LED strip.

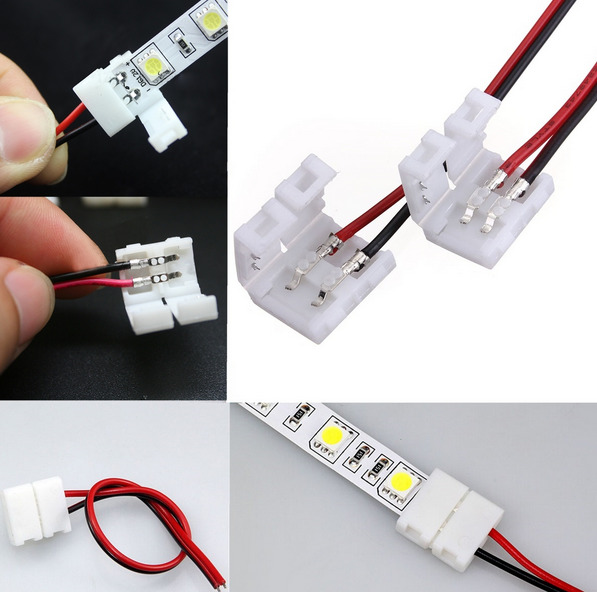

- With help connector, whose contacts oxidize over time.Photo 06. Connectors.

Eliminate traces of oxide and all mechanical damage. Avoid shorting contacts. Do not try to repair old connections, it is better to use new connectors - this will protect you and your room from short circuits. If all connections are OK, the problem is in the tape itself.

The tape is flexible, but do not forget that it is based on a flexible printed circuit board, which has restrictions on bending, it can bend and burst. In this case, the board inside the tape may be damaged immediately after soldering, at the very beginning of the tape. Try applying voltage from the power supply to the following pins. They are located a little further, in places incision ribbons. Observe polarity (+,-). To do this, it is convenient to solder crocodiles on the wires from the power supply, and clamp the needles in them.

Half not lit

A special case of the problem described above. There may be a break in the PCB circuit in the area of the tape. It is necessary to ring and remove the damaged section from the circuit. It can also be determined by checking the voltage supply, to the cells in series one after the other, to each contact. Connect carefully. Use connecting contactors or a soldering iron. Remove flux residue with alcohol.

Ribbon flashes or flickers

There may be several reasons:

- the power supply is damaged - in this case, you can check the tape by connecting it to a working power source. If the problem is solved, replace the power supply with a new one;

- with a working power supply, check the DC wires that are located in the section of the “power supply - tape” circuit, also pay attention to the connections, poor contact is possible;

- provided that the power supply is normal, the contacts are also - the problem is in the tape section: the printed circuit board track is broken. Delete this area. How to determine it is indicated above.

- the LEDs have expired - replace the tape.

Flashing, flickering or not lit individual parts

This is also a common problem. Occurs from damage to one of the LEDs connected successively, or the resistance that is soldered in front of them.

The increased brightness of the tape is also the cause of this malfunction. In such cases, it is best to replace the damaged section of the tape. With good soldering skills, you can fix this problem yourself. We will talk about this next.

Testing an LED with a Tester

LEDs have a lifespan and eventually fail. Let's consider, how to test led.

To check the soldered LED with a multimeter, you must put the device into the diode test mode:

- anode - positive electrode, the red probe of the tester is connected;

- cathode - negative electrode, the black probe of the tester is connected;

- on the display we will see the magnitude of the voltage drop;

- if you change the polarity - there should not be a voltage drop, such results tell us about the health of the LED.

How to check the LED on the board

The verification procedure remains unchanged, the only thing that is needed is to make remote probes. If you do not have special adapters for removing probes, then sewing needles fit perfectly into the connector for checking the LED. Thus, we simply make an adapter with our own hands.

Do-it-yourself dialing

You can design a homemade device that consists of two medical needles, wires and a battery. We wind a wire on each needle, connect each end to a battery. Not soldering LED, we throw needles on the contacts of the LED and see if it works or not. Remember: any LED is powered by a constant voltage, and therefore has a plus and a minus. Observe polarity. The error does not disable the LED, but it does not light it either. I put a video on how to make the device below.

Homemade mini tester:

Differences between 220 V and 12 V LED strip

AT there are tapes for sale, which at one end have a plug and a small box - a diode bridge. This is what they are, 220 V tapes, which are used mainly for outdoor decorative work. The multiplicity of the cut of such a tape is 1 m. It uses a full-wave rectifier, which is a vulnerable link in the circuit. Such tapes are dangerous for people because the mains voltage reaches three hundred volts, so it is strongly not recommended to touch them.