How to solder an LED

LED bulbs use less energy than incandescent bulbs. They also last much longer, so the owners of houses and apartments are gradually switching to economical lighting. But despite the long service life, LED bulbs can gradually fail due to the burnout of the LEDs installed inside.

When one of the chips fails, this is not a reason to throw away the light bulb, it can be fix. To do this, you need a tester to determine the breakdown, then you can replace the damaged element or connect the circuit. In the latter case, the repair will negatively affect the life of the lamp, it will become dimmer. Therefore, it is better to replace the chip with another one. To do this, you need to know how to solder LEDs.

How diode elements are arranged

Diodes are installed inside the LED lamps. They are also mounted in rulers and ribbons, which are often used in advertising banners. There are no pinouts here.The diodes are mounted on a plastic or aluminum printed tape and are connected to each other by a special track during soldering. Removing an LED or installing a new one is not difficult if you have a gas burner, soldering iron and flux at hand.

In most cases, LED lamps are made of aluminum, which is able to provide efficient heat dissipation to the radiator. A different number of LEDs are installed inside, which determines the power. The contact leads of the diode tape have a substrate on the reverse side for heat dissipation. It is soldered to the heat sink. Removing one of the diodes, it will also have to be soldered.

Safety Compliance

In the process of repairing any device that is powered by the mains, safety precautions must be observed. LED lighting devices, like incandescent bulbs, are connected to a 220 volt network. Therefore, the master must be careful and take into account the recommendations:

- after turning off the lamp, you must manually discharge the capacitors. To do this, the conclusions are short-circuited with a metal device with a dielectric handle.

- during the soldering process, the soldering station must not be left unattended, this can cause a fire;

- turning on the installed bulb is better to turn away, as there is a possibility that due to possible errors it will explode.

Soldering LEDs is not an easy process for a beginner. Repairs should be started only if you have experience with a soldering iron, are familiar with the design and principle of operation of the chips.

How to desolder and resolder an LED

Before you start soldering, you need to study the instructions and acquire materials and tools for work. Do not forget to check the purchased LEDs. Sometimes masters neglect this rule, which is why the work has to be done twice.

What is needed for work

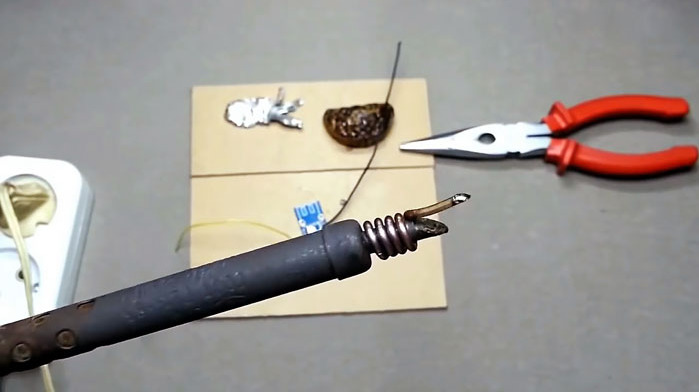

To solder an LED from an aluminum board, you need:

- tweezers;

- blade;

- soldering iron (recommended with a thin tip);

- flux;

- holder.

If there is no soldering iron with a thin blade, you can make a nozzle from copper wire.

Soldering temperature

The indicator diode, which is mounted on a printed circuit board, consists of conductive legs and a glass bulb. Outwardly, it resembles a small light bulb. For soldering, you must use a soldering iron with a power of not more than 60 W. The admissible tip temperature is 260 degrees. SMD diodes do not have current-carrying elements. They are replaced by special contact pads on the board. In this case, a 12 W soldering iron is used for soldering.

Step-by-step instructions for desoldering

The first step is to remove the aluminum board. To do this, the lamp housing is separated from the ceiling. Here you can use a knife, carefully so as not to damage the elements. The platform is attached to the base with a pair of wires (plus and minus). They should be unsoldered by fixing the board on the holder. The board can be removed from the aluminum base without tools.

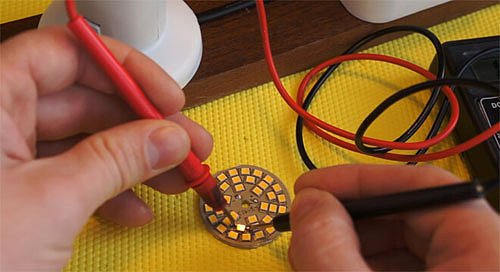

Before you start soldering the LED, you need to take a tester and go through all the chips in order to verify their performance. In most cases, damaged elements can be seen visually. A black dot appears on a burned-out LED.

It is better to check with a tester, as sometimes a breakdown does not entail visible changes.

It is recommended to pay special attention to the quality of soldering. If the marriage was allowed in production, this will affect the functionality of the chips.

Soldering scheme

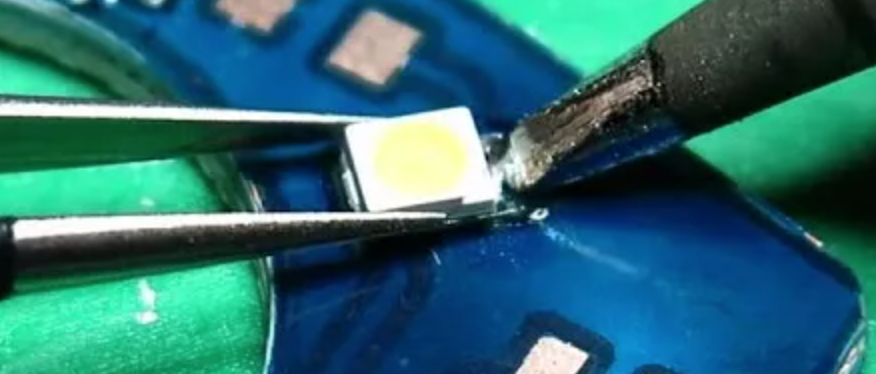

When all burnt diodes are identified, you can start soldering. The board is fixed on the holder. After the burner is carefully brought to the back of the board. After 3-5 seconds, the soldering should loosen, which will make it possible to disconnect the diode. A serviceable element must be fixed before the base cools down.. To do this, a drop of flux must be placed on the contact pad. The chip is installed from above, taking into account the polarity.

Then it is heated again, while the crystal needs to be slightly pressed. Hold the diode until the contact "legs" are securely fixed in the solder. If there is no LED, you can solder a small piece of wire in its place. The lamp will continue to work, but the light will be dimmer. This option is only suitable if more than 10 chips are installed on the board.

According to the same scheme, diodes from corn lamps are soldered. This can be done if bulb small in size and assembled according to the classical scheme. A hairdryer is sometimes used instead of a soldering iron, but it takes more time to work.

Before soldering the chips, the ruler should be fixed to prevent damage to the conductive tracks. Tin is melted with a soldering iron, a blade is simultaneously advanced between the board and the output. When all pins are released, the substrate is detached from the board.

Video example: Replacing LEDs in a lamp with an iron.

Common soldering mistakes

Inexperienced craftsmen often make the following mistakes:

- installation of the connector on current-carrying contacts. This will result in a bad connection;

- work with a soldering iron heated to 300 ° C and above. This will provoke the burning of current-carrying threads;

- the use of an aggressive solution will corrode the contacts;

- non-observance of polarity when installing the diode on the board.

In order for the new diode to work for a long time and not burn out, before installing it on the board, remove the solder residues from it. For this, it is recommended to use a wire braid from a shielded wire. Errors made during operation can cause an instantaneous burnout or explosion of the lamp when turned on.