Do-it-yourself LED strip soldering technology

LED strip is popular in the world of lighting technology. It is a convenient solution for creating various types of lighting. During the installation process, it often becomes necessary to connect two canvases to each other.

How and why to connect segments of LED strip

The LED strip is sold in rolls. A full bay is not always needed, usually small sections of the web are required, powered from a single voltage source. A solid canvas can be cut - but only in specially marked places. Having mounted pieces of tape in place, they must be connected in series, or each segment must be powered by its own cable from its own power source, which is not economically feasible and does not add reliability to the system.

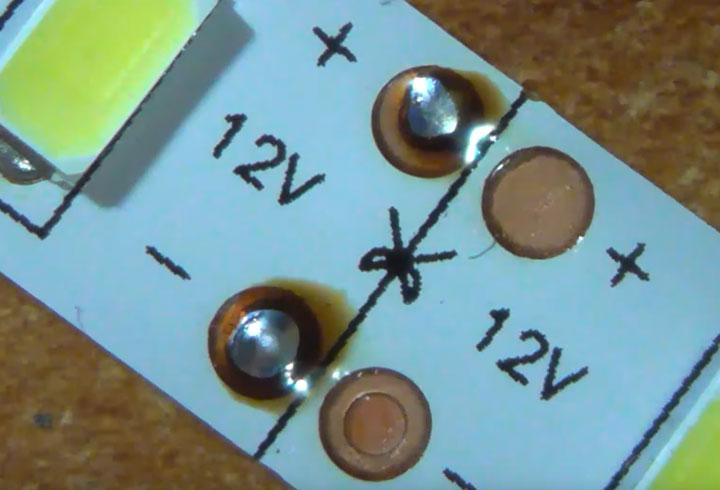

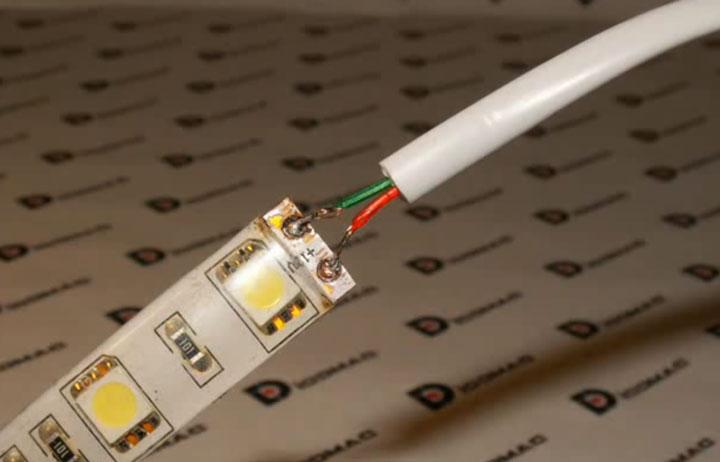

You can connect the canvases with pieces of wire - every two pieces of tape are connected to each other with two wires, taking into account the polarity. If a ribbon type RGB or RGBW, then it is necessary to comply with the connection of conductors at both ends of the sheets. The cross section of the wires must be designed for the full current of all segments of the web.

| Conductor cross section, sq. mm | 0,5 | 0,75 | 1 | 1,2 | 1,5 |

| Permissible current, A | 11 | 15 | 17 | 20 | 23 |

If there is no table at hand, you can use the rule - 1 sq. Mm. section of a copper conductor allows you to pass a current of 10 A. This value is much too high, in fact, the permissible current through such a section is at least two times lower (depending on the laying method). But there is no risk of making a mistake in a smaller direction, and this is precisely what can lead to unpleasant consequences. In addition, with an open laying, the cross section of the conductor must not only provide a current carrying capacity, but also have sufficient mechanical strength, so the wire thickness in these cases is overestimated.

Solder or connector

For this purpose, connectors seem to be very convenient. They allow you to quickly and without the use of additional tools to connect two pieces of tape together. In real life, not everything is as good as at first glance:

- when using connecting accessories, the contact patch area is small;

- this method does not guarantee a tight pressing of the contact pads.

Both of these factors lead to increased contact resistance at the junction. The currents consumed by the tape are large, and can be up to several amperes. This leads to overheating of the contact point, burnout and complete loss of the electrical connection. In the worst case scenario - to the fire. Besides exposed copper contact prone to oxidation, and this leads to even greater loss of conductivity, heating, even more oxidation, and so on in a circle.Taking into account the fact that there are 4 sources of unreliability per connection (2 wires on both sides each), the choice of a good master is unambiguous - only soldering.

Tools and materials

The soldering process itself is simple, but requires some skill. Therefore, for those who have never held a soldering iron in their hands, it does not hurt to practice on wire scraps.

For actual soldering you will need:

- soldering iron power of 30-40 watts. Less power will not allow the soldering place to warm up sufficiently and turn the whole process into torment. The increased power will easily lead to overheating of the soldering point, especially in the absence of experience. It is even more convenient to use a soldering station, but it is expensive and it is not economically feasible to buy one just to solder a few pieces of tape.

- Flux. They can serve as a classic rosin. It is more convenient to use soft fluxes or liquid type LTI. Solid rosin can be crushed and dissolved in alcohol.

- Solder. Almost any solder with an adequate melting point can be used. For example, classic POS-60 or other lead-tin solders. You can use pure tin, but it is expensive and does not provide advantages.

Important! Under no circumstances should liquid and soft acid-based fluxes be used! Flux splashing is inevitable during the soldering process. If it gets on the conductors or solder points of the LEDs, the acid will inevitably cause corrosion in the future, which will lead to the loss of tape performance.

Also, alcohol or acetone will not hurt to remove flux residues after soldering.You will also need a copper wire (better flexible stranded) and tools for its preparation:

- wire cutters for cutting the wire of the desired length;

- fitter's knife for stripping insulation (it is even better to use a special puller);

- to seal the soldering point, you will need electrical tape or heat shrink tubing of the appropriate diameter.

If the process will be carried out without assistants, it is convenient to use the clamp stand as a "third hand".

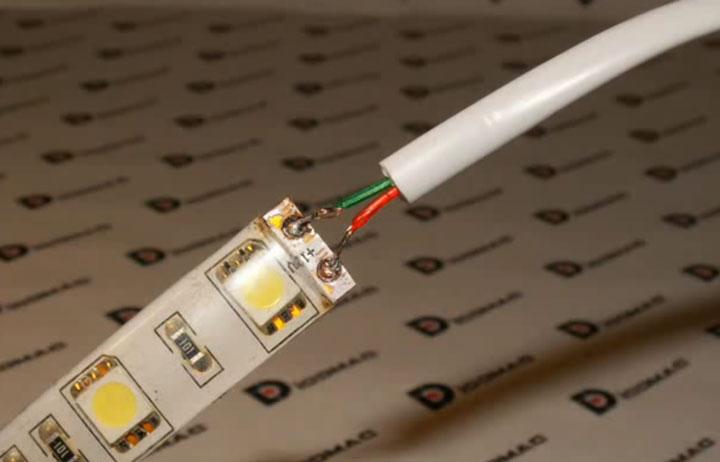

The process of soldering conductors to pads

First you need to prepare the wires:

- slice pieces of conductors of the desired length;

- remove the insulation from both sides at a distance of 5-7 mm with a fitter's knife or a special stripper.

Next, the surfaces to be soldered must be irradiated. The stripped ends of the wires are covered with flux:

- if a liquid flux is used, the cleaned areas must be moistened with it;

- with a soft flux, the ends free from insulation are abundantly lubricated;

- if rosin is used, a small amount must be melted and transferred to free areas so that the stranded wire is saturated with flux, and the surface of the solid wire is completely wetted.

The video describes in detail the process of tinning the wires.

Next, you need to dial a little solder with the tip of the soldering iron. The surface of a single-core wire must be covered with a lead-tin melt from all sides. A stranded wire is instantly saturated with solder if a heated tip with a melt is applied to it.

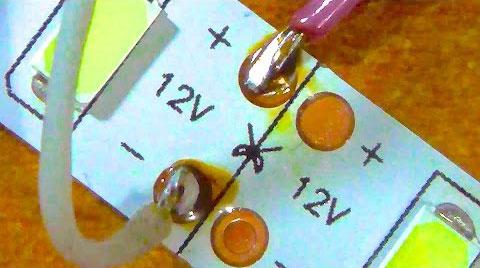

Contact pads are also wetted with molten, liquid or soft flux and tinned in the same way. Solder should be collected so that a small tubercle of metal is formed on the site.

Further, it does not hurt to once again lubricate the tinned surfaces with flux. After that, you need to attach the wire to the site at the right angle and heat the junction with a soldering iron with a small amount of solder. It is necessary to solder the LED strip quickly enough so as not to damage the base of the canvas. To speed up the cooling of the solder, it is recommended to blow on the place of soldering intensively. After completion of work, the flux residues must be washed off with alcohol or acetone.

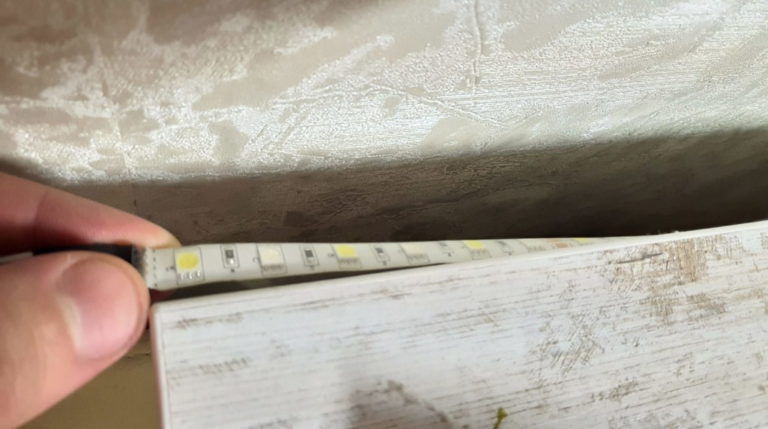

If the tape has a silicone coating

For outdoor mounting, it is convenient to use silicone-coated tape. The process of soldering conductors to such a tape is almost the same, but before starting work, you need to remove the silicone in the area with contact pads with a knife, and then the LED strip can be soldered in the usual way.

If necessary, at the end of work, the cutting site can be sealed with a transparent silicone sealant, but only a neutral composition should be used. Acidic can cause corrosion of conductors and components.

How to get good soldering

Beautiful, neat, high-quality soldering comes with experience. But the training time can be reduced by immediately taking the simple points as a rule:

- The soldering iron tip must be well tinned. If it is copper, then it must be cleaned with a file, removing carbon deposits and giving the working surface the necessary shape. Next, you need to turn on the soldering iron in the network, after a little heating, lower the tip into the flux and wait until it reaches the operating temperature. After that, you need to quickly rub the work surface with a piece of solder. If the tip has not been used, it is advisable to forge it on a hard surface - this will reduce the tendency to burn and extend the service life.

- If the tip is galvanized steel, then it cannot be cleaned with a file - the applied layer is easy to tear off, and the working surface will become unsuitable for work. It is impossible to irradiate it, it will have to be thrown away. For the same reason, you cannot tin such a sting with acid flux - it will “eat” the coating.

- If a soldering iron with temperature control is used, it is necessary to set the temperature of the tip 5-10 degrees higher than the melting temperature of the solder. If this is not done, then due to the installation error and due to the inaccuracy of the proportions of metals in the solder, the tip will not be able to turn the solder into a liquid, but will only bring it to the state of slurry. In this case, high-quality soldering is not worth talking about. See the table below for the melting point.

- During tinning and soldering, it is not necessary to save on flux. Excess and spatter can then be removed with a solvent.

- Solder should be used as much as needed. Excess solder does not impair the quality of soldering at all, but a lack of solder will not allow you to get a reliable connection.

- It is necessary to solder the conductors in the shortest possible time to avoid overheating of the base.

- After removing the soldering iron tip and until the solder is completely solidified, the conductors to be connected must be completely immobile - a “third hand” is very useful for this.

| Solder type | POS-33 | POS-40 | POS-60 | POS-90 |

| Melting temperature | 247 | 238 | 183 | 220 |

In general, it is not difficult to solder the conductors for the LED strip. All you need is basic skills and dedication.