How to check the LED for serviceability

LEDs are semiconductor devices of artificial light. Their work is based on the emission of light photons and electromagnetic energy in the visible, infrared and ultraviolet frequencies. Light emits a p-n junction in the contact zone of diodes of p- and n-types of conductivity during a constant stabilized current flowing through it. In this case, light is emitted (about 6 - 15% of the consumed electricity) and heat is released - at least 80 - 90% of this energy.

The main causes of diode failure

There may be several reasons for the failure. Testing is done according to a special technique. Main causes of failures:

- Thermal breakdown as a result of overheating and destruction (destruction) of the crystal. Accompanied by the burning of the lacquer coating and the plastic case. The photo shows a burned-out LED on the printed circuit board of a retrofit lamp, an analogue of a MR16 halogen lamp. In one of the buildings SMD2835 due to overheating of the crystal, the yellow phosphor applied to it burned out. A brown dot is visible on the element with reference designation D11.

- Electrical breakdown p-n junction. The direct operating voltage of the diode, depending on the color of the glow and the materials of the p-n junction, lies in the range from 1.5 to 4-4.5 V. The reverse voltage is several volts more than the direct one. Therefore, voltage surges can cause it to become unstable at the output. If they exceed the reverse voltage of the diode, a breakdown is possible.

- mechanical break. Silver or gold wires supply current to the semiconductor crystal from the case contacts. Vibration or shock can cause them to break.

- Degradation. A gradual decrease in the characteristics of the LED, primarily the brightness and hue of the glow. The fall in brightness is normalized 30, 50 and 70% of the original. The brightness drops by 5-10% during the first 1000 hours of operation for most devices. A drop in brightness by 50 - 70% requires replacement of the lamp, module, ruler or tape. Sometimes it occurs in 15 - 20 thousand hours.

Recommended: Checking the LED lamp with a multimeter

Degradation occurs in the phosphors of white LEDs and in secondary optics elements - lenses built into the housing or mounted on its surface. Under the action of light, the lenses become cloudy, light transmission and luminous flux decrease.

“LED dialing with a multimeter, diode dialing” is a slang term that got into lighting engineering from low current electrical engineering.When it was necessary, for example, to check the health of the conductors in the cable, they took a battery, a battery or a portable power supply and a conventional electromechanical bell. A battery and a bell were connected to the first contact of the cable connector with a “crocodile”. At the opposite end of the cable, the remaining wires were connected in series to the first wire. The ringing bell showed the serviceability of the wires.

They also checked the short circuits of the wires in the cable to each other. The method was also used after checking the call with an ammeter. The name of the operation stuck with electricians, and then moved to electronics. They just didn’t use a bell, but a tester, which was called differently - an ABOmeter, an ohmmeter, a multimeter.

You can check the health of the LED with a multimeter directly on the board or by unsoldering it. The device is used to test DC and AC circuits. They measure voltage, resistance of resistors in ohmmeter mode, serviceability and performance of capacitors, rectifier diodes, p-n-p and n-p-n transistors, and more.

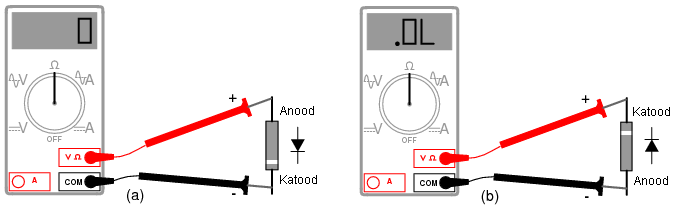

The red test lead and multimeter wire is the positive pole or "+" circuit of the power supply and diode anode. Black wire and probe - a circuit connected to the cathode and the negative pole of the source. The multimeter is switched on for measuring direct current in the range from 0 to 20 mA or 0.02 A. The multimeter displays 15.7 mA, which means that the diode is open and its operating current is the specified value. An LED of normal brightness at this current strength should glow and warm up a little.

In the diode designation scheme, the transverse dash is the cathode, the triangle is the anode. The blue rectangle represents a fixed resistor. It limits the line, i.e. operating current of the LED.

When voltage is applied directly without current limitation, it is possible to exceed the operating value and thermal breakdown of the diode.

Testing an LED with a Battery

To test the LED with a battery, you need to assemble the circuit according to the diagram.

On the diagram:

- LED1 - device being checked.

- 9V – power supply (9V battery).

- VAΩ - a measuring device for measuring V - voltage, A - current, Ω - resistance, AVOmeter or multimeter. The circuit works in voltage measurement mode.

- R1 - current limiting resistor.

- R2 - a variable resistor that sets the brightness of the LED.

Resistor R2 on the multimeter sets the rated operating current. A good LED element gives light. Faulty - does not light.

The term "multimeter" is a transliteration of the international name "Multimeter". It is formed from the terms Multi - a lot and meter - to measure. It has the names "tester", "AVOmeter" - from Ampere-Volt-Ohmmeter.

A modern multimeter is a universal measuring instrument with a digital display.

Another name for the device is "tester" - Cyrillic transliteration of the international term tester - tester, checker, tester.

How to call without soldering

To check the LED without soldering, you need to analyze the device circuit. If there are no circuits parallel to the diode, it can ring without soldering.Parallel circuits can influence the result.

On the probes of the multimeter you need to solder sharp steel needles. The entire needle, except for the tip and probe, must be insulated, for example, with a heat-shrinkable tube. A probe with a needle is used to pierce a layer of protective varnish until it comes into contact with the terminal of the diode on the case or the contact pad on the board. Measuring the resistance in the forward and reverse direction shows the health of the device. Direct resistance - tens to hundreds of ohms. The reverse is hundreds of kilo-ohms or more.

Checking SMD diodes in a flashlight

This is done only if from a flashlight can take out the board with SMD LEDwithout breaking it, and if there is a spare board with the same diode. The check is performed by replacing it with a board that is known to be good.

Video

For clarity, we recommend a series of videos.

Ringing in a light bulb.

With the help of a tester.

When there is no special device.

The SMD device can be tested in many ways. The simplest and most affordable is checking with a multimeter. Allows you to test the diode without soldering it. Choose the method convenient for you.