Features of the choke for fluorescent lamps

All fluorescent lamps have an element in their design that limits the current strength - a choke, or ballast. It stabilizes the network from uncontrolled growth of indicators, excluding ripples.

What is a choke

The inductor is an inductor (to be precise in terms, in this case, an inductive coil) located on a ferromagnetic core (usually made of a soft magnetic alloy). This coil, like any conductor, has ohmic resistance, as well as inductive reactance, which manifests itself in alternating current circuits. The design of the inductor (ballast) is such that reactance prevails over active. The whole structure is placed in a case made of metal or plastic.

Choke classification

AT fluorescent lamps chokes of electronic or electromagnetic type (EMPRA) are used. Both types have their own characteristics.

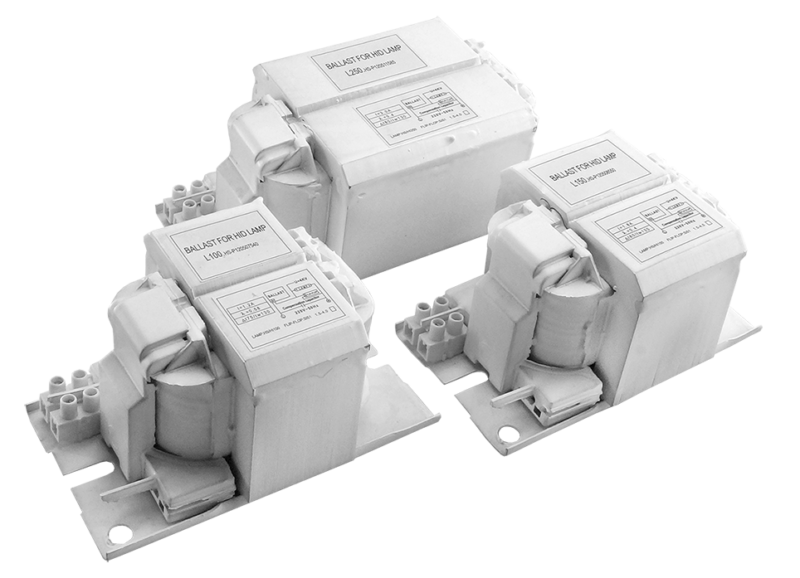

An electromagnetic choke is a coil with a metal core and a winding of copper or aluminum wire. The diameter of the wire affects the functionality of the luminaire. The model is quite reliable, but power losses up to 50% cast doubt on its effectiveness.

Lamps with electromagnetic chokes are cheap and do not require special adjustment before use. But they are sensitive to voltage fluctuations and even slight fluctuations can lead to flickering or unpleasant buzzing.

Electromagnetic structures are not synchronized with the mains frequency. This results in flashes just before the lamp is ignited. Flashes practically do not interfere with the comfortable use of the lamp, but they negatively affect the ballast.

The imperfection of electromagnetic technologies and significant power losses during their use lead to the fact that electronic ballasts are replacing such devices.

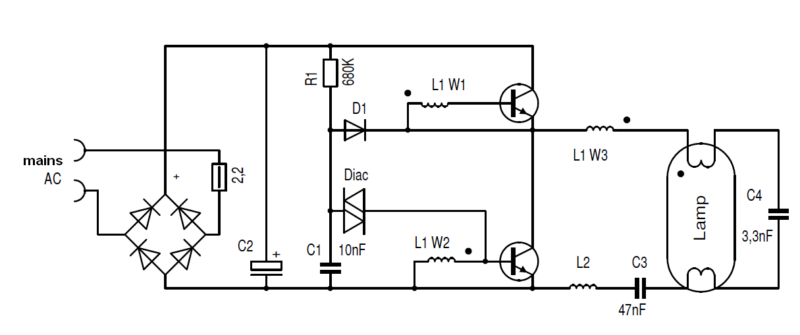

Electronic chokes are structurally more complex and include:

- Filter to eliminate electromagnetic interference. Effectively extinguishes all unwanted vibrations of the external environment and the lamp itself.

- Device for changing the power factor. Controls the phase shift of the AC current.

- Smoothing filter that reduces the level of AC ripple in the system.

- inverter. Converts direct current to alternating current.

- Ballast. An induction coil that suppresses unwanted interference and smoothly adjusts the brightness of the glow.

Sometimes in modern electronic ballast you can find built-in protection against voltage surges.

What is it for

Any inductor performs the functions of a series resistor. However, unlike conventional resistance, it provides better filtering without AC ripple or appliance hum.

In modern technology, two power configurations are used: capacitor and choke. In the first case, the inductor is not required to supply voltage, but as an additional filter it has no equal.

How to choose an electromagnetic choke

When choosing an electromagnetic choke, pay attention to the parameters:

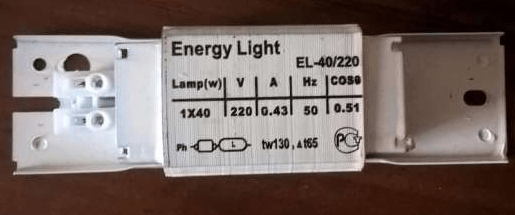

- Working voltage. Standard home networks require 220 - 240 V, 50 Hz devices.

- Power. Should match the power of the lamp. If two or more lamps are to be connected, the inductor power must correspond to the sum of their powers.

- Current. The allowable indicator is indicated in Amperes on the case.

- Power factor. It is advisable to select devices with maximum parameter values. For EMPRA, it usually does not exceed 0.5, so an additional capacitor is required.

- Working temperature. Ambient and throttle temperature range at which all elements remain serviceable.

- energy efficiency. It is determined by the class in accordance with the accepted gradation. EMPRA is characterized by middle classes B1 and B2.

- Capacitor parameters. The operating voltage and capacitance of the capacitor, which is connected in parallel to the mains.

How does the lamp start and work

A fluorescent lamp, unlike a conventional one, is not connected directly to the network. This is due to its structure and principle of operation.

To ignite it, you need:

- ensure the emission of electrons from cathodes made in the form of filaments;

- ionize the interelectrode gap filled with mercury vapor using a high-voltage pulse.

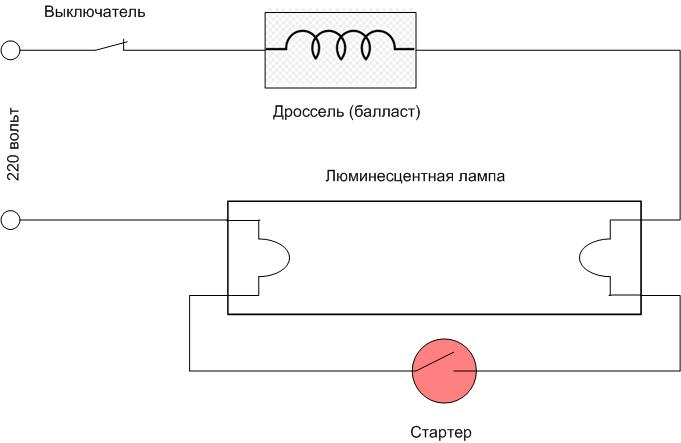

Then the lamp will continue to work until the power is removed due to the arc discharge between the electrodes. In the initial position, the power switch is open, the starter contacts are also open.

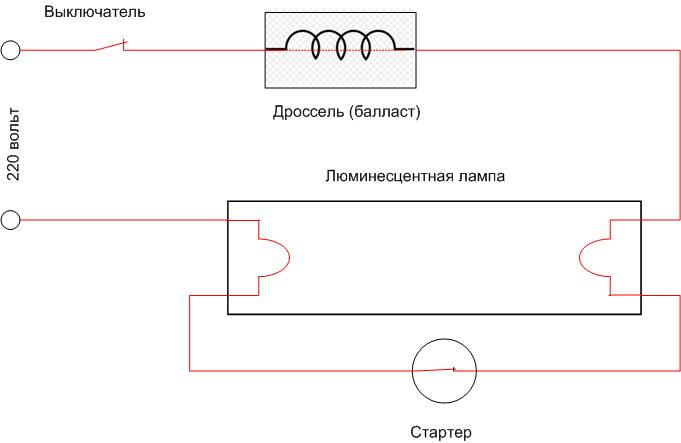

At the first moment, after applying voltage to the circuit, a small current (within 50 mA) flows through the circuit choke - lamp filament 1 - glow discharge in the starter bulb - lamp filament 2. This low current heats up and closes the starter contacts and current flows through the filaments, heating them up and emitting electrons.

This current is limited by the inductor resistance. Without such a limitation, the filaments will burn out from overcurrent.

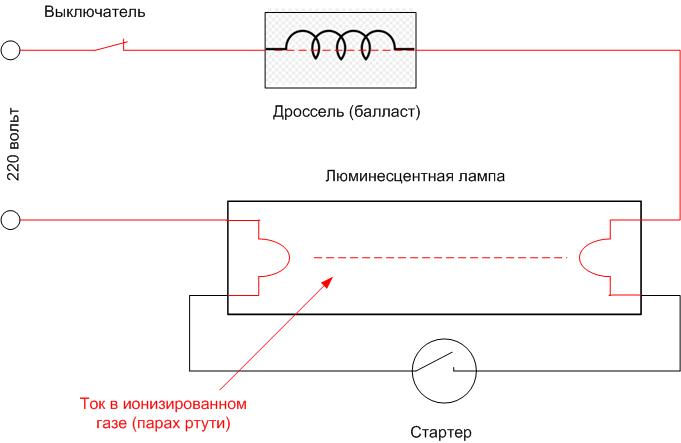

After the starter contacts cool down, they open. By breaking the circuit with a large inductance, a voltage pulse (up to 1000 volts) is formed, which ionizes the discharge gap between the two filaments of the lamp. A current begins to flow through the ionized gas, which causes the mercury vapor to glow. This glow initiates the ignition of the phosphor. This current is also limited by the complex resistance of the starter. And the starter does not affect the further operation of the lamp.

Obviously, the starter plays an important role in the operation of the lamp:

- limits the current when the lamp filaments are heated;

- generates a high voltage ignition pulse;

- limits the gas discharge current.

To perform these functions, the ballast must have sufficient inductance to create the required AC reactance and to form a high-voltage pulse due to the phenomenon of self-induction.

In some cases, the starter cannot ignite the gas in the lamp bulb the first time and repeats the current supply procedure about 5-6 times. In this case, the blinking effect is observed when turned on.

The throttle helps to get rid of this effect. It turns the alternating low-frequency voltage of the household network into a constant one, and then inverts it back into an alternating one, but already at a high frequency, the ripples disappear.

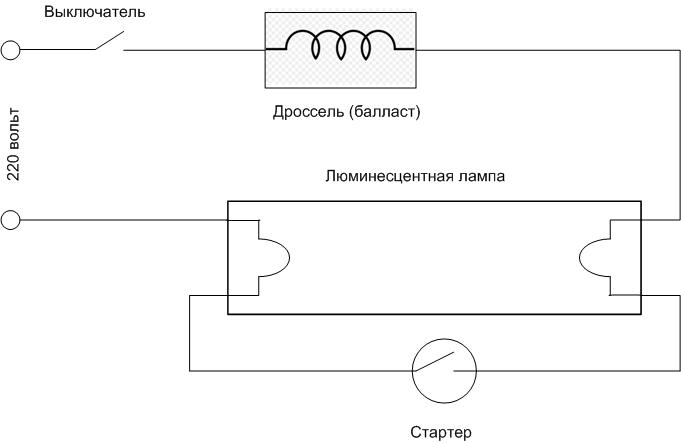

Lamp connection diagram

Wiring diagram simple: a circuit with a choke and a lamp connected in series. The system is connected to a 220 V network at a frequency of 50 Hz. The inductor performs the functions of a corrector and voltage stabilizer.

Throttle problems and their diagnosis

Fluorescent lamps sometimes fail. The reasons are different: from factory defects to improper operation. In some cases repairs can be done forces and simple tools.

Recommended for viewing: Repair of electronic ballast of a fluorescent lamp

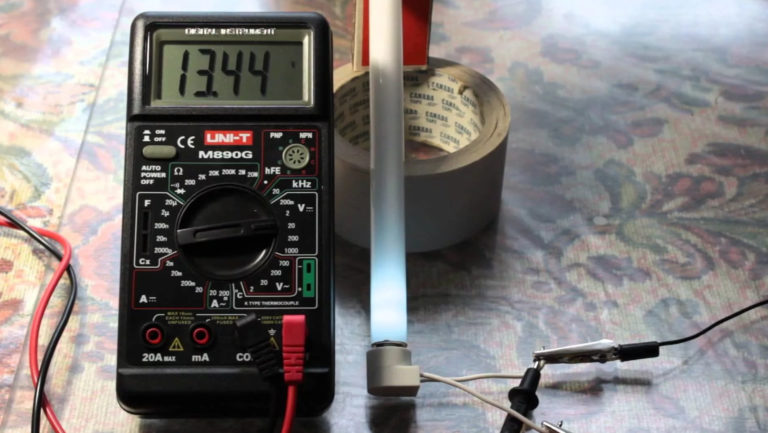

Before renovation it is necessary to accurately identify the node of the breakdown. To do this, the lamp and all related equipment will have to be disassembled.

Required tools:

- a set of screwdrivers with fully insulated handles;

- mounting knife;

- wire cutters;

- pliers;

- multimeter;

- indicator screwdriver;

- a coil of copper wire (section from 0.75 to 1.5 mm²).

Additionally, a new starter, serviceable lamp or choke may be required.It all depends on which node failed.

The most common problems:

- The lamp does not turn on and does not respond to the starter. The reason may be in any of the elements, so you need to change the starter first, then the lamp, simultaneously checking the operation of the circuit. If it doesn't help, then the problem is in the throttle.

- The presence in the flask of a small discharge in the form of a snake indicates an uncontrolled increase in current. The cause of the malfunction is precisely in the throttle, which must be replaced. Otherwise, the lamp will quickly burn out.

- Ripple and flicker during operation. Replace sequentially first lamp, then the starter. More often the culprit is the inductor, which ceases to stabilize the voltage.

Typically, a throttle malfunction is eliminated by replacing it. However, if desired, you can disassemble the element and try to restore performance. It requires serious knowledge in electrical engineering and a lot of time. Given the low cost of a new throttle, this is impractical.