How to repair fluorescent lamps with your own hands

Fluorescent lamps are now used in various fields. The spread of LED lamps has not been able to remove them from the market. They have many advantages over other lighting devices. However, sometimes problems occur due to various factors. It is better to study the problems and repair methods of various fixtures in advance.

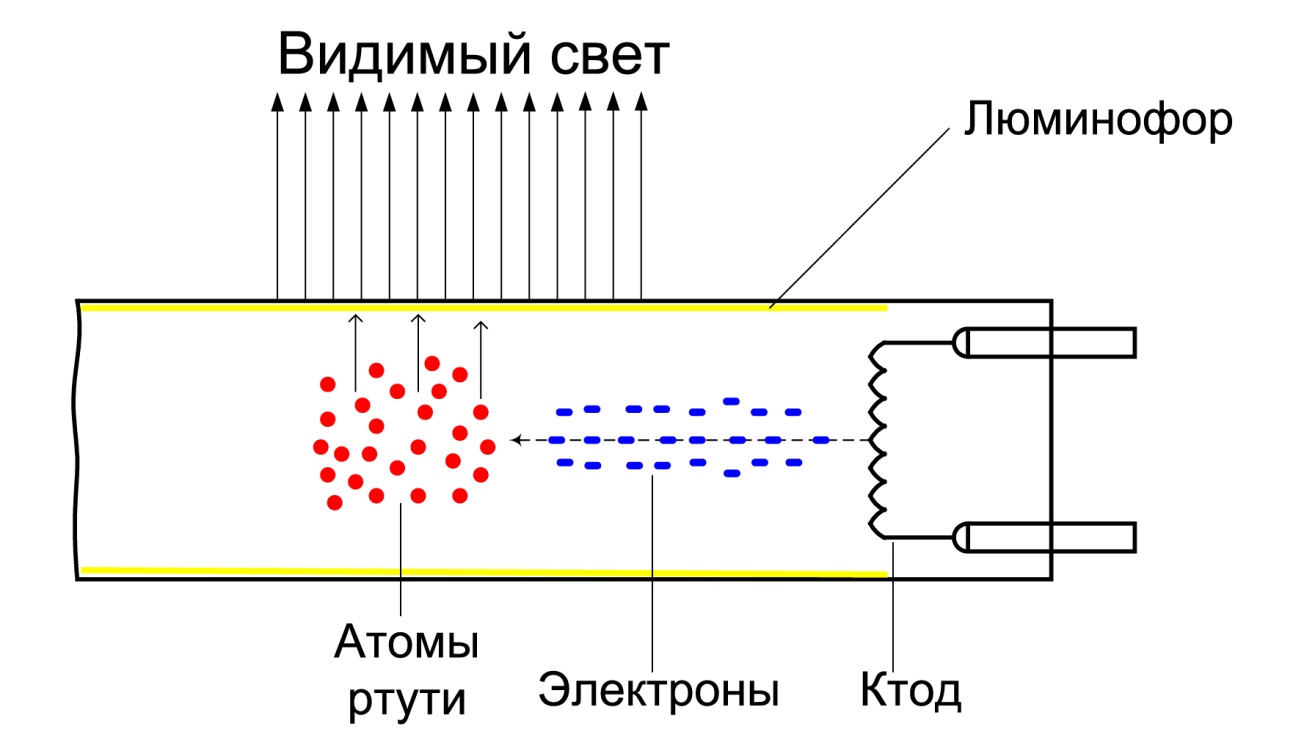

The principle of operation of a fluorescent lamp

The principle of operation of a fluorescent lamp simple. Voltage is applied to the contacts inside the tube, and electron emission occurs in the inert gas and mercury vapor in the tube. Radiation appears in the ultraviolet range. The human eye cannot see such a glow.

To obtain visible light, the inside of the tube is coated with a phosphor. The hue and temperature of the glow depend on its composition.

The functions are controlled by an electronic unit, which includes a ballast.

List of faults

The main control element of any fluorescent lamp is a ballast. It can be electromagnetic or electronic. In the first case, the device includes throttle and a starter, in the second control is carried out by other components.

In most cases, the breakdown of the lamp is associated with a malfunction of the electronic circuit, aging of the elements or burnout. Any repair begins with identifying the cause.

Thematic video: Options for checking a fluorescent lamp.

Choke lamp

To test a lamp with a choke, you can connect a control light to the circuit. If a:

- the device does not light up - a break in the ballast, the throttle is faulty;

- burns brightly - inter-turn short circuit in the ballast;

- the lamp blinks or does not shine brightly enough - the throttle is working.

The inductor itself may have an open circuit, a short circuit of different windings, a short circuit of turns in one winding, or a magnetic circuit malfunction. Separately allocate a breakdown on the body.

Luminaire with electronic ballast

In such a lamp, the lamp itself, the integrity of the wiring, and the serviceability of the cartridge holders are checked. If each element is serviceable, it is necessary to replace the ballast itself.

Often it is he who fails when the transistor burns out, which can be seen with the naked eye. If there are no visual problems, ring the contacts with a multimeter.

In the circuit, a low-resistance fuse is also considered a weak point. Sometimes the cause of the malfunction lies in the damage or burnout of the diode bridge. The lamp does not turn on in this case.

Recommended for viewing: Repair of a fluorescent lamp with electronic ballast

Flashing lamp

Traditional incandescent light bulbs burn out in an instant and unexpectedly. Fluorescent lamps wear differently.First, the device starts blinking when turned on, which indicates a change in the chemical composition of the gas inside the flask. Blinking causes the electrodes to burn out.

Often there are darkened areas with soot. It's almost impossible to fix this. However, some simple manipulations can extend the life of the lamp.

The reason for the flashing is a malfunction of the EM or electronic ballast. Connect a new light fixture to test.

In some cases blinking due to the voltage drop in the network. In serviceable devices, this phenomenon should not be, since the ballast stabilizes the voltage.

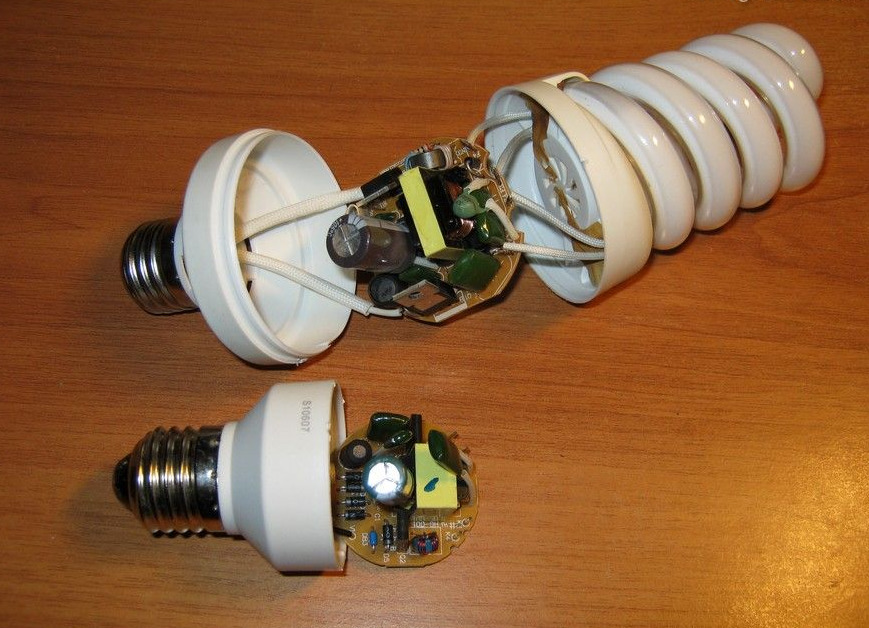

Dismantling the fluorescent lamp

For repair, you need to disassemble the electrical appliance. It is necessary to disassemble the fluorescent lamp in the place where the inscription with the name of the device and its technical characteristics is applied. It is necessary to pry off the case with a regular flat screwdriver.

If darkening is noticeable at the ends of the flask, it is better to throw it away. Typically, flasks fail in about 2 years.

Next, the contacts of the flask are called with an ohmmeter. The resistance should be a few ohms and decrease with increasing power.

If the elements are in order, you need to inspect the electronic ballast board. The burnout of any element on it in most cases can be seen immediately. This is especially true for burnt resistors.

The process of repairing fluorescent lamps

Repair consists of several steps:

- Checking the voltage in the network and the quality of the contacts.

- Replacing the light bulb with a pre-serviceable flask.

- If the flashing persists, it is worth replacing the starter and checking the throttle or completely replacing the ballast.

For repairs, you will need a soldering iron, a multimeter and screwdrivers.It is desirable to have an understanding of the operation of electronic circuits and safety precautions.

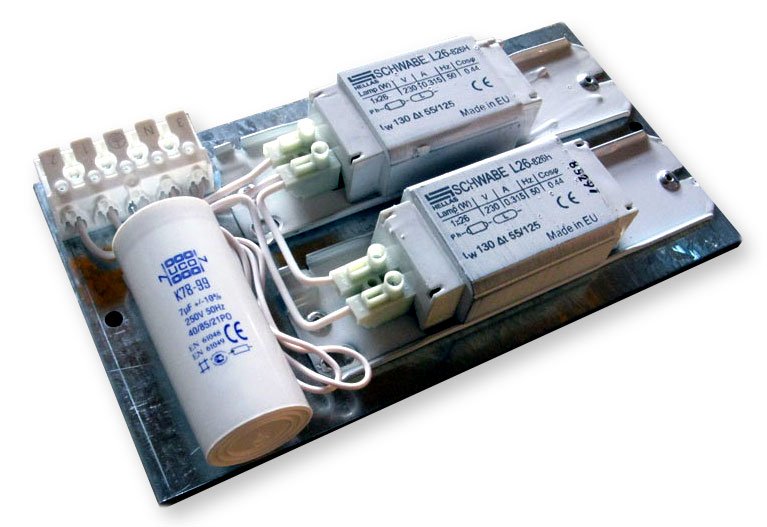

electromagnetic ballast

Repair of the device with ballast provides:

- Checking capacitors. Capacitors reduce electromagnetic interference and compensate for reactive power deficiencies. They often leak current. It is best to check for such a malfunction first, in order to eliminate unnecessary costs for expensive capacitors.

- Calling the ballast for breakdown. It is advisable to use a multimeter with the ability to measure inductance. If a breakdown is detected, change the ballast or install an electronic analogue. Both a new component from the store and a serviceable one from another lamp will do.

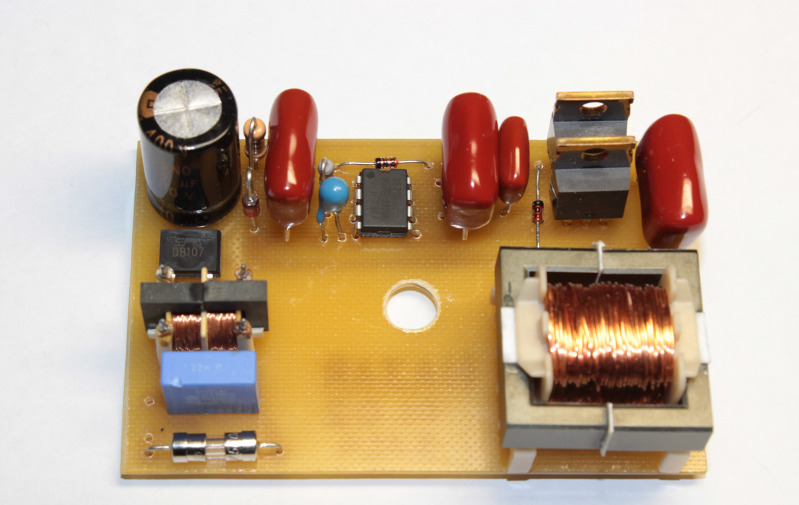

Electronic ballast

electronic ballast may differ in schemes, but the principle of operation remains the same. Filaments with certain inductance values are used, which feed the oscillatory circuit. There are capacitors, coils and an inverter with transistor switches.

An oscilloscope or frequency generator is used for diagnostics. Repair begins with inspecting the board and looking for a burned out component. First, the fuse is checked, often causing a malfunction.

Any ballast components can fail. Therefore, it is worth consistently check with a multimeter capacitors, resistors, transistors, diodes, chokes and transformers.

When checking, it may be necessary to desolder the components, since without desoldering, reliable indicators can only be obtained by checking for a breakdown.

Defective elements are replaced with new ones. Soldering is carried out carefully, since the components are sensitive to overheating.

Homemade electronic ballast

Experienced electricians and radio amateurs are switching from standard electronic ballasts to do-it-yourself electronic ballasts. In this case, the repair is practically no different from repairing the purchased electronic ballast.

How to extend the life of a fluorescent lamp

Many radio amateurs have learned to extend the life of burned-out fluorescent lamps by starting by increasing the voltage applied to the electrodes.

This helps to get, when turned on, a voltage peak exceeding 1000 V. The value is enough to start the process of cold ionization of mercury vapor and create the necessary discharge in a gaseous environment. The result is a stable glow even with a burnt coil.

You can limit the current with a resistor or an incandescent lamp. This approach avoids rapid burnout. fluorescent lamp during operation. The winding of the resistor can be done independently with nichrome wire.