Characteristics and appearance of SMD LEDs

The desire to miniaturize electronic devices has led to the creation of leadless radio elements. This trend has not bypassed LEDs either - SMD devices have significantly replaced conventional output devices in many areas, and in lighting they have practically squeezed them out of the market.

What is SMD LED

SMD LED belongs to the Surface Mounted Device category - a device mounted on a surface. If conventional output (true hole) elements require a hole to be drilled for installation on the board and solder legs on the reverse side, then the SMD radio components are soldered directly to the tracks located on the upper plane of the printed circuit board.

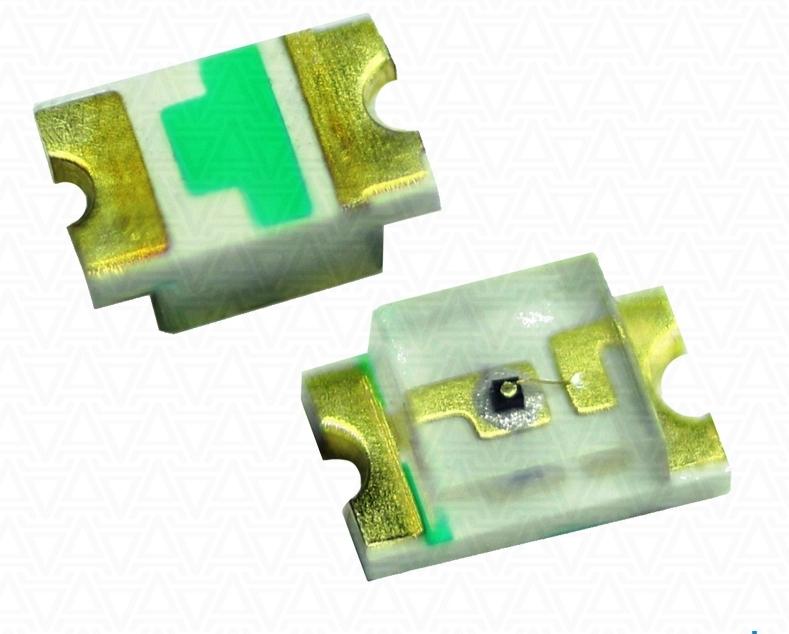

Fundamentally, the light-emitting element in the SMD format is arranged in the same way as its output prototype. A p-n junction from a semiconductor is fixed on a ceramic substrate, which has a pronounced glow effect when a direct voltage is applied. From above it is closed with a lens made of a transparent compound. If necessary, a layer of phosphor is applied on top. The main difference is the lack of flexible leads.Pads are provided for soldering directly to PCB polygons.

Advantages and disadvantages of SMD LEDs

Overall, the pros outweigh - as a result, finished products are smaller in size, weight and cost.

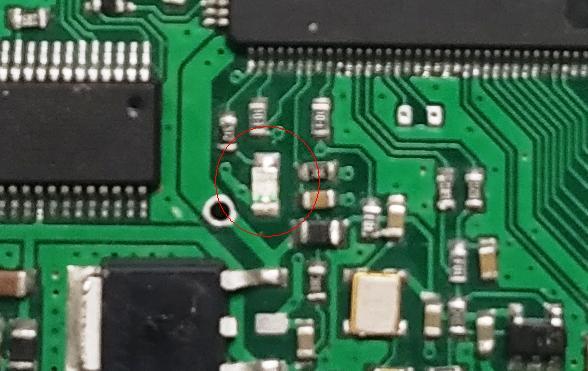

There is a myth about the non-repairability of electronic equipment manufactured using SMD elements. But this is only a myth. It is quite possible to restore the efficiency of such equipment; this will require a small additional equipment, as well as increased experience and qualifications of the master.

Kinds and types of SMD

Conventionally, almost all LEDs are divided into two global categories:

- intended for lighting;

- designed to indicate the status of electronic devices.

For the first category, SMD elements almost completely replaced the output elements, in the second - they left them a narrow niche. Therefore, the same classification can be applied to surface mount radiating elements.

The dividing line runs along the technical specifications:

- for lighting elements, the luminous flux is important and a color close to natural is required;

- indicator elements are important not so much color and brightness as contrast to the surrounding background.

Therefore, for indication, you can use LED with the glow of the p-n junction, and for lighting - only with a phosphor coating. Although this is also quite arbitrary - no one forbids the use of devices with a phosphor and a white glow for indication.

All this applies to LED optical, visible range. As a separate type of SMD LEDs, devices with an emission spectrum that lies beyond the perception of the human eye should be mentioned. These include ultraviolet and infrared emitters. The former are used to create compact sources of UV radiation. They are used for currency detectors, to search for biological traces, etc. The latter are used in signal transmission systems - in remote controls for household equipment, in burglar alarm systems, etc. These LEDs are also available in SMD format.

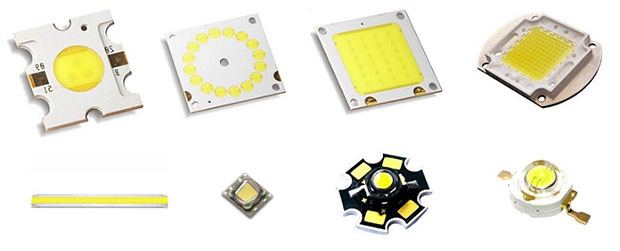

It is also necessary to mention LED-matrices for lighting systems, produced using the most advanced COB technology to date. Contrary to popular belief, this production principle does not at all contradict the SMD format. And COB LEDs are produced, including in the form of a Surface Mounted Device.

Dimensions of SMD LEDs

The type of LED is indicated by the dimensions of its housing. Thus, the common standard size of LED 5050 means that the light emitting element is placed in a shell 5.0 mm long and 5.0 mm wide.

Important! The marking indicates only the size of the case. The electrical and optical characteristics of LEDs of even the same size may differ depending on the type and number of installed crystals, therefore, to unambiguously determine the parameters, it is necessary to use the technical specifications for the LEDs.

Correspondence of the sizes of common SMD LEDs in the table:

| Size | Assembly length, mm | Assembly width, mm | Number of emitting p-n junctions | Luminous flux, lm | Rated current, mA |

| 3528 | 3.5 | 2.8 | 1/3 | 0.6..50 | 20 |

| 5050 | 5.0 | 5.0 | 3/ 4 | 2..14 | 60/80 |

| 5630 | 5.6 | 3.0 | 1 | 57 | 150 |

| 7020 | 7.0 | 2.0 | 1 | 45..60 | 150 |

| 3020 | 3.0 | 2.0 | 1 | 8..10 | 20 |

| 2835 | 2.8 | 3.5 | 1 | 20/50/100 | 60/150/300 |

The dimensions of the LEDs intended for indication are marked according to the international standard EIA-96 in inches. The most common cases are 0603 and 1206.

| Size designation | Size in inches | Metric dimensions, mm | Metric fit |

| 0603 | 0.063''x 0.031'' | 1.6 x 0.8 | 1608 |

| 1206 | 0.126''x 0.063'' | 3.2x1.6 | 3216 |

The same rule applies here - in cases of the same size, LEDs of different glow colors, different operating currents, etc. can be made. Therefore, the parameters for the EIA designation cannot be completely determined.

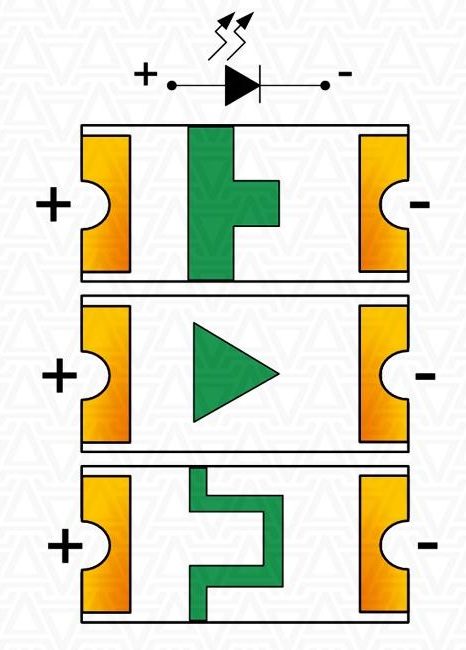

SMD marking

The SMD format arose as a result of the desire to miniaturize electronic components, so there is no place to put information about the type and technical characteristics on them. Even if you set such a goal, the inscriptions will be too small for comfortable reading. Therefore, marking is reduced only to the designation of the terminals of the device.This is important because although LEDs are in the class of diodes, they are of little use for blocking reverse current due to their low tolerance for reverse voltage. If a conventional diode is installed without respecting the polarity, this manufacturing defect is easy to identify and correct. The light emitter, after power is applied, will most likely fail. Even if a problem is detected before voltage is applied, it is problematic to dismantle a miniature indicator LED using a soldering dryer - melting a transparent plastic casing that closes the p-n junction is as easy as shelling pears.

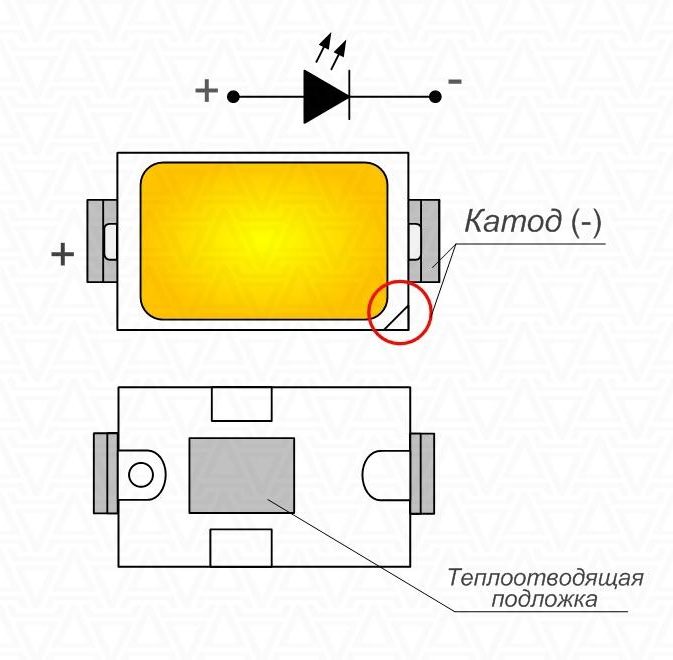

Therefore, when mounting indicator LEDs, attention should be paid to the presence of a mnemonic pattern indicating location of the anode or cathode.

Elements intended for lighting usually have a bevel, tide or notch on the body - in most cases it means the cathode. But there is no guarantee that the manufacturer strictly observes this rule. Therefore, in case of doubt, it is better to play it safe and verify LED (at least one from the batch) with a multimeter.

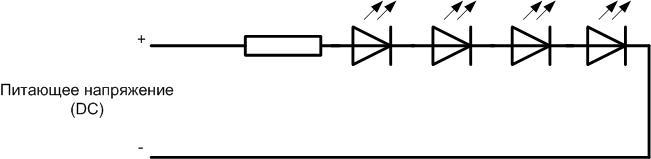

It was mentioned that the SMD element is no different from a conventional LED, with the exception of a leadless package. Therefore, the switching scheme will not differ either. The supply voltage to the LED must be applied through a driver or a limiting resistor, observing the polarity.

LEDs can be combined into serial chains, which are then connected in parallel into matrices. This combination achieves the desired power at a given supply voltage.

When repairing lighting fixtures with the replacement of radiating elements (one or more) during operation, the board should be protected from bends and mechanical stress. All elements of the SMD format under such conditions are prone to the formation of microcracks in the body, violation of the integrity of the soldering, invisible to the eye. As a result of such a repair, you can get several faulty LEDs instead of one and a loss of time to troubleshoot. It’s better not to remove the board at all, but it is installed on a radiator that has a large mass and heat capacity, so a soldering iron or a high-power hair dryer will be required to warm up the solder. If there is confidence that a particular LED is out of order, you can try not to solder it, but to bite it out. But care must be taken not to mechanically damage the printed conductors. When reinstalling a serviceable element, it must be remembered that LEDs are sensitive to overheating and try to avoid prolonged soldering.

Thematic video:

When developing homemade lighting devices, one should be aware of the problem of heat removal from LEDs. The board must always be installed on an additional heatsink of sufficient area, and for this it must have an appropriate design (no elements on the back side, holes for screws for fastening, etc.).

Despite some shortcomings, the SMD electronic component format has taken root in the electronics industry. The contribution of miniature leadless elements to the reduction in the cost of electronic equipment in the last decade is very significant. LEDs are also involved in this process.