How to make a flashing LED with your own hands

Features of human perception are such that we better notice not the value of the parameter, but its change. Therefore, intermittent sounds and glow are used in all warning and alarm systems. This makes it easier to attract the attention of the operator or other people. This solution is also used for other purposes. For example, in advertising. Therefore, the flashing LED is widely used in a wide variety of electronic circuits.

What is needed to make

You can buy ready Light-emitting diode, which will flash when power is applied. In such a device, in addition to the usual p-n junction, there is a built-in electronic circuit, made according to the following principle:

The basis of the device is the master generator. It generates pulses with a relatively high frequency - a few kilohertz or tens of kilohertz. The operating frequency is determined by the parameters of the RC chain. Capacitance and resistance are constructive - they are the elements of the LED device.In this way, a large capacity cannot be obtained without a significant increase in the dimensions of the device. Therefore, the RC product is small, and operation at high frequencies is a necessary measure. At a frequency of several kilohertz, the human eye does not distinguish between the blinking of the LED, and perceives it as a constant glow, so an additional element is introduced - a frequency divider. By sequential division, it reduces the frequency to a few hertz (depending on the supply voltage). In terms of weight and size, such a solution is more profitable than using a capacitor with a large capacity. The smallest supply voltage for a finished blinking LED is about 3.5 volts.

How to make a blinking LED

It is not difficult to make a blinking LED yourself. In many cases, only a few additional elements will be needed. Simple circuit options are shown below.

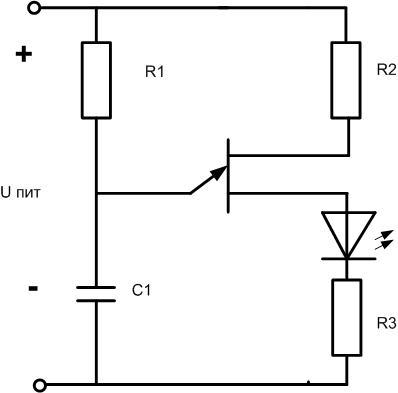

Flasher on one transistor

It is easy to make such a flasher with your own hands on just one transistor.

The circuit is assembled on a unijunction transistor. You can install a domestic element KT117, you can choose a foreign analogue. The oscillation frequency is inversely proportional to the product of R1C1. The ratings and purpose of the elements are indicated in the table.

| R1 | C1 | R2 | R3 |

| From a few kilo-ohms to tens of kilo-ohms. Together with C1 sets the generator frequency. | To obtain a frequency of 1..3 Hz, you must select a value of 10..100 uF, adjust the frequency by selecting R1. | Limits the current through the transistor and LED. It is selected depending on the supply voltage, at 10 V to set the current to 10 mA, the nominal value must be 1 kOhm. | Several tens of ohms |

The supply voltage can range from 4.5 to 12 volts. The disadvantage of the circuit is the use of a large oxide capacitor - much larger than the LED itself. But it contains few elements and works immediately after an error-free assembly. If a unijunction transistor cannot be purchased, you can make its analogue on two bipolar transistors.

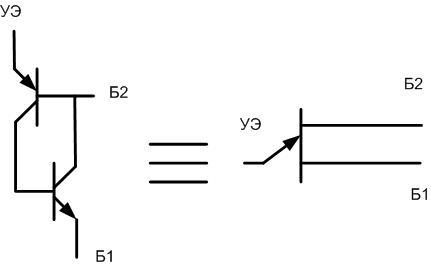

You can use any two transistors of the p-n-p and n-p-n structure. For example, domestic pairs of KT315 and KT316, KT3102 and KT3107 or any other devices of Russian or foreign production.

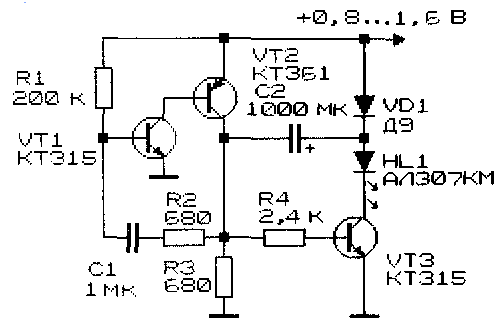

Battery flashing LED

This circuit is simple, easy to manufacture, does not need adjustment (except, perhaps, the selection of the parameters of the timing chain). But it has a feature that can become critical in some situations - it will require a voltage of 4.5 V to power it. Such a voltage will require a minimum of three AA batteries or CR2032. And even a slight decrease in power due to discharge can lead to the inoperability of the circuit.

Almost all common light-emitting elements require a voltage of 1.6 V (and often 3 V) to glow, so it is impossible to build a simple blinking LED circuit for power from a 1.5-volt battery. But you can make a relatively complex one - with a doubling of the voltage.

On transistors VT1, VT2, an oscillator is assembled that sets the frequency and duration of flashes (they are determined by the chains R1C1 and C1R2, respectively). During the pause, the capacitor C2 is charged almost to the power level.During the glow, the VT3 key opens, VT2 closes, and the container is connected in series with the power source. This doubles the voltage across the LED.

Diode VD1 must be germanium. On a silicon diode in the open state, the voltage drop will be about 0.6 V - in this case, this is a lot.

It will be useful to read: Blinking LED without any circuits

LED strip manufacturing

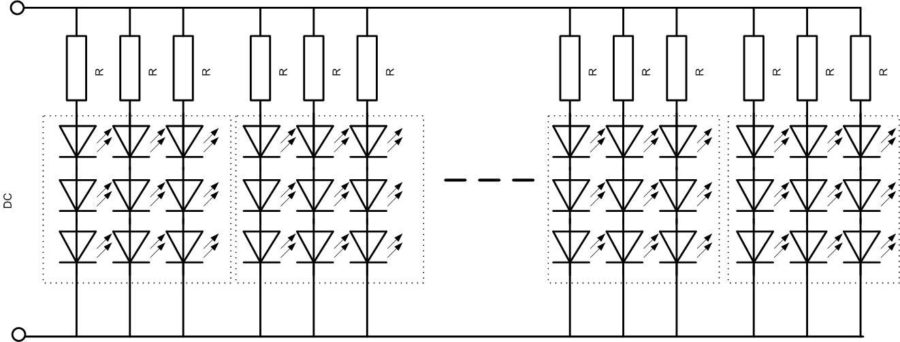

The LED strip has become a popular lighting device that has become widespread. It is a flexible base on which parallel chains of connected in series limiting resistors and LEDs. Such a tape is supplied in the form of a bay, which can be cut in certain places.

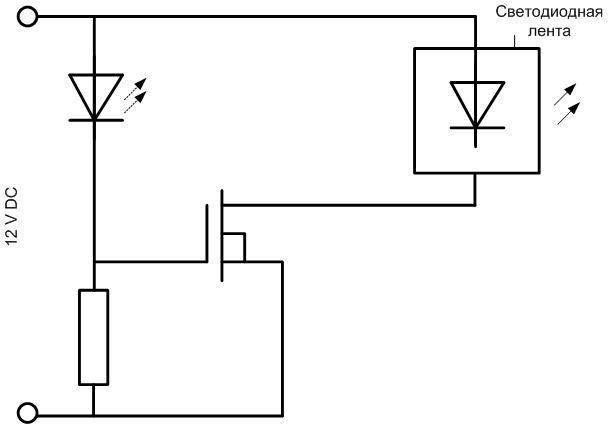

It can be seen from the diagram that the lighting device differs from a single LED by an increased supply voltage due to the series connection of several elements and an increased current consumption caused by the parallel connection of many chains. Therefore, the power source must be powerful enough, therefore - overall. So there is no point in saving on the dimensions of the circuit elements for building an LED strip flasher. The paradox is that for such a tape you can build an ultra-simple signal generator.

For this you will need:

- flashing LED;

- current-limiting resistor;

- powerful field effect transistor (you can use IRLU24N or similar, suitable in terms of parameters);

- actual tape;

- source of power.

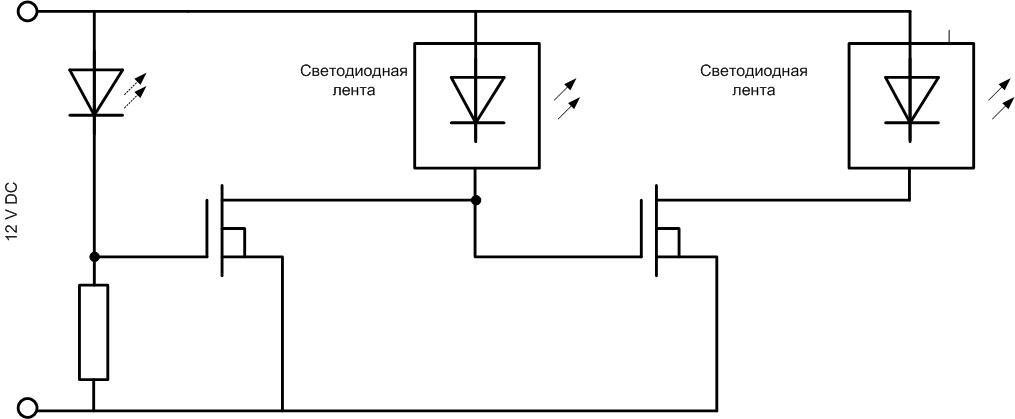

The LED will turn on periodically, applying and removing voltage at the gate of the transistor.The key will turn on and off in time to turn the LED strip on and off. The flasher can be increased if a second lighting device is required to be turned on and off in antiphase with the first.

If one tape is enabled, the other one will be disabled, and vice versa.

A separate power supply can be used for each tape, but the common wire (negative line) must be connected.

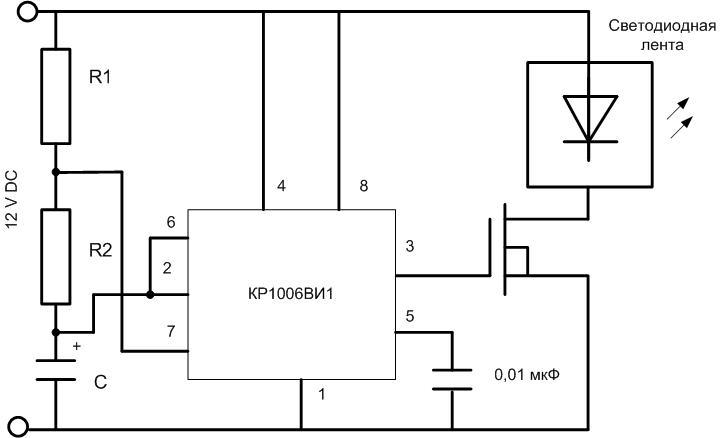

Such a scheme has undeniable advantages - simplicity and low cost. But there is also a drawback - the frequency and duration of blinking are determined by the parameters of the LED, and they can only be changed by the supply voltage at the same time. In order to be able to set separately the period of flashes and their duration, a more complicated scheme is needed. To do this, you need a KR1006VI1 chip or its foreign counterpart NE555. Advantages of this chip:

- small sizes;

- low power consumption;

- the ability to separately adjust the duration of the output pulses and the pause between them.

Oscillation parameters are set by the elements R1, R2, C:

- switching duration t1=0.693(R1+R2)*C;

- pause duration t2= 0.693*R2*C;

- generation frequency f=1/0.693*(R1+2*R2)*C.

If desired, you can put variable resistors instead of R1 and R2. In this case, you can quickly adjust the flashing mode.

The power supply of the microcircuit should not exceed 15 V. When using a 24-volt tape for the chip, it is necessary to provide a separate source or make a 24/15 volt stabilizer (the simplest parametric one on a zener diode or on an integrated stabilizer 7815 will do).

Making a flasher from an LED or tape is easy.For success, you need a minimum of knowledge of electrical engineering, simple skills and a few radio elements.