Description of COB type LEDs

Not so long ago, the market began to be filled with LED-lamps made using COB technology. Immediately after the appearance of such products, information about them began to acquire the character of myths. This review is an attempt to separate truth from fiction and marketing tricks.

What is COB LED

Since the advent of SMD LEDs, engineering has not stood still. The developers of many manufacturers solved the problems of reducing the size of lighting equipment, increasing light output, simplifying and reducing the cost of installation, assembly, etc. Now it is difficult to establish who first came up with the idea not to enclose each p-n junction in a separate case coated with a phosphor, but to place several gallium arsenide crystals in one shell. But the first sample of such products appeared on the market in 2003 from Citizen Electronics.

The idea turned out to be a breakthrough. In addition to solving the above problems, it became possible to concentrate the radiating elements on a relatively small area and obtain less light scattering.This technology is called COB - chip-on-board, "chip on board". Perhaps a more accurate translation would be the phrase "element on the board" or "crystal on the board."

For a long time, the production of matrices made according to this principle was constrained by the complexity of gluing LEDs onto a substrate. The thickness of the adhesive must be strictly verified: a decrease in the layer leads to a decrease in the fastening strength, an increase leads to a decrease in the efficiency of heat removal. In 2009, this problem was solved and COB technology began its triumphal march through the world of lighting technology.

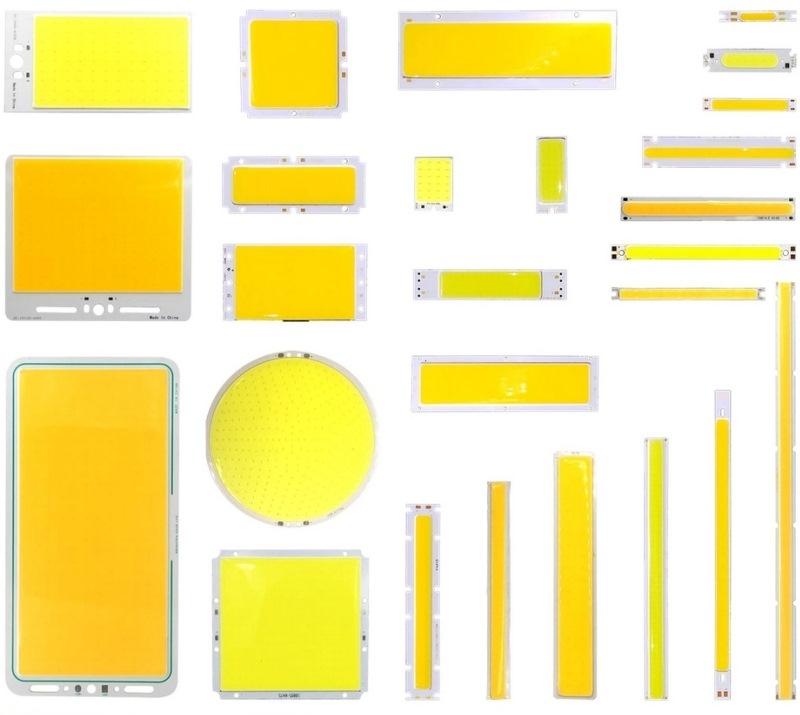

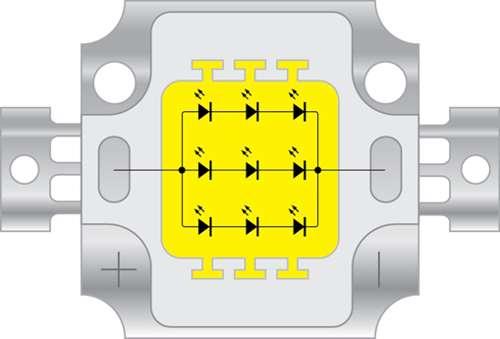

A module produced according to this principle contains a matrix of LEDs without housings placed on the base. Due to the absence of shells, it was possible to increase the density of the radiating elements and increase the brightness taken from a unit surface. In some cases, LEDs are filled with a transparent compound for strength. The upper part of the shell is coated with a phosphor.

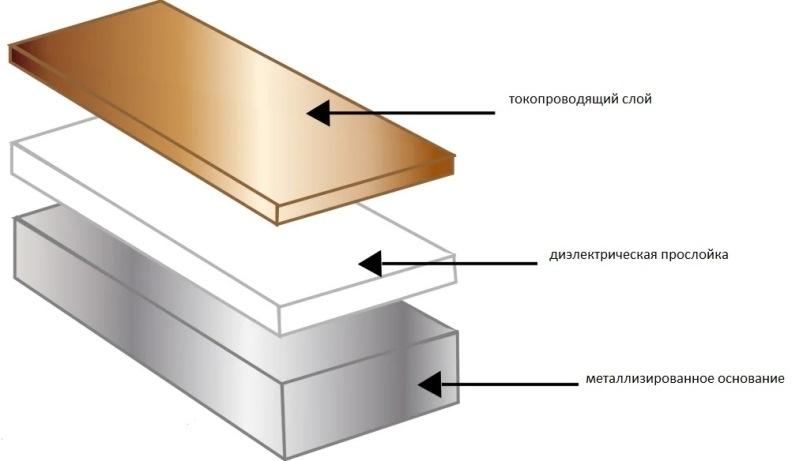

The printed circuit board is produced according to the usual technology, it consists of conductive tracks located on a dielectric base. A metal plate with high thermal conductivity is glued from below, and the product gets a finished look.

Important! In most cases, a standard heatsink is not enough to ensure the normal operating temperature of the LEDs. An additional external heat sink must be used.

Typical values of the luminous flux of matrices with a crystal size of 0.762 * 0.762 mm, depending on the power, are indicated in the table.

| Electrical power, W | Number of elements, pcs | Luminous flux, lm |

| 10 | 9 | 450-550 |

| 30 | 30 | 1800-2200 |

| 50 | 50 | 2550-2750 |

| 100 | 100 | 4500-5500 |

In fact, the parameters may vary slightly due to additional conditions.

Types

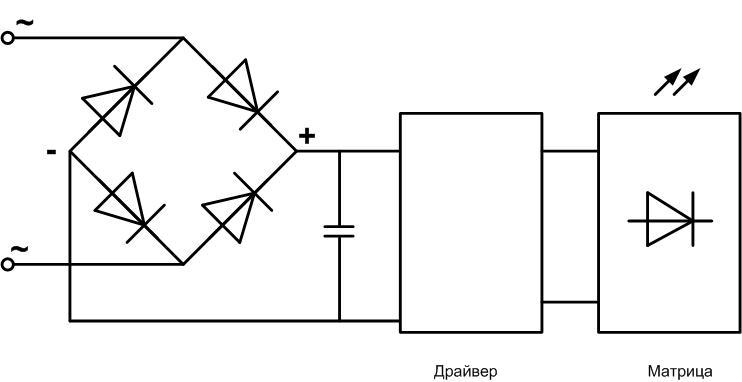

Recently, COB LEDs with built-in drivers have appeared on the market. “On board” is now not only a matrix, but also rectifier elements, as well as a current stabilization microcircuit through radiating elements. As you can see, additional elements are not hidden under a common casing, but are mounted on a separate board and combined into a module.

This type of COB LED technology is a single unit, to which it remains only to supply voltage.

Principle of operation and characteristics

New principles are not supposed to be the basis for the operation of COB LEDs. All the same p-n junction from gallium arsenide, indium phosphide or other materials. The same recombination of the main charges with the emission of a light quantum when a direct voltage is applied. The same monochromatic light with a narrow spectrum. The same principles for obtaining inaccessible colors - when power is applied, the radiation of the LEDs (in the optical range or UV) initiates the glow of the phosphor. This well-known method makes it possible to obtain colors that cannot be achieved with the direct glow of semiconductor junctions. Also, the problem of heat dissipation has not gone away. The novelty of the elements is only in the production technology, which allows bringing light-emitting devices to a new consumer level.

Control

Controlling a COB LED comes down to switching the supply voltage, and in this respect there are no fundamental differences from conventional devices. You can turn this element on and off:

- manual switch for the appropriate voltage;

- electromagnetic relay or starter;

- electronic key (transistor, thyristor).

It is only necessary to take into account that the power of such an LED can reach 100 W, and the operating voltage is 220 V.The switching element must have the appropriate parameters.

Recommended for viewing: COB led vs smd led

Pros and cons

Important! Given the low cost of producing COB LEDs, these disadvantages are gradually losing their significance. Everything goes to the fact that it becomes more cost-effective to replace the matrix, rather than restore it.

Manufacturers' declarations about increased light output in relation to power due to the use of new production principles, most likely, should be attributed to marketing moves. It has already been noted that no new principles are supposed to be the basis for the operation of COB matrices. And some increase in light output can be associated with the natural development of technologies for the production of phosphors and semiconductor crystals.

Life time

COB manufacturers claim an average lifespan of around 30,000 hours. This is about 3.5 years of continuous operation. For conventional LEDs in the technical specifications, this period is usually indicated within the range of up to 50,000 hours (5.5 years).It is often concluded that the reliability of COB elements is low. In fact, experience in the operation of new light-emitting devices has not yet been accumulated. All figures are derived from calculations that often do not take into account operating conditions. And it is unlikely that any of the manufacturers conducted real life tests lasting several years. There is no point in them - during this time new technologies and materials will come.

It should be borne in mind that the warranty periods for both those and other elements are set approximately the same - in the region of 15,000 hours. Everything else is forecasts and pure marketing. Therefore, all information about the service life today is in the nature of declarations, and should be treated with caution.

COB LED lamp

Another advantage of the new technology is that matrices of any shape and size can be produced. In most cases, round and rectangular (square) devices are produced, from which lamps of various configurations can be made.

The corn lamp, which takes its name from the discreet elements reminiscent of crop grains, has been given a new look. Now there are no luminous points, the surface has become solid, the radiation is more uniform. The size of such lamps is now limited by the requirements of the mechanical strength of the matrix, but it is hoped that the development of technologies in the near future will allow to circumvent this problem.

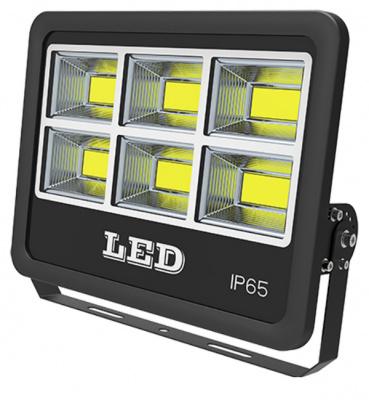

An LED spotlight using such matrices can have either one radiating element or several, depending on the required brightness of the glow. Luminaires are not yet equipped with one matrix, which replaces several smaller ones, due to the mentioned size restrictions.

Wiring diagram

The connection scheme depends on the execution of the matrix. If these are just parallel chains of elements, then they must be connected to a household single-phase 220 V network through a rectifier or driver for the appropriate voltage and current, like ordinary single LEDs or assemblies.

If the rectifier and driver are "on board", then the connection is no different from a conventional incandescent lamp. The already mentioned “corn”, for example, has a standard base for screwing into a cartridge.

Pinout

An LED, like a conventional diode, is a device that conducts current in one direction. Therefore, when connecting, you must observe the polarity. The anode must be connected to the positive output of the power source, the cathode - to the negative.

It is easy to determine the location of the COB-matrix pins - the marking is applied directly to the case. The conclusions are marked with the symbols "+" and "-". If the assembly can be connected directly to the AC voltage circuit, then the outputs are marked L (phase) and N (zero).

There is an opinion that lighting elements produced using COB technology will completely replace SMD LEDs in the near future. In fact, this is unlikely to happen. After all, SMD elements did not completely replace output elements, although they significantly pressed them. It is most likely that the situation will be the same here - each technology will occupy its own niche.