How to check the choke of a fluorescent lamp

Until recently, the fluorescent lamp was the only alternative to the incandescent lamp. Its use helped to save energy and, to a certain extent, to choose the color temperature of the lighting. But not every home master could cope with one problem - troubleshooting and eliminating them in additional elements that accompany fluorescent lamps.

Table of main faults

The main types of malfunctions that occur in practice in chokes are summarized in the table.

| Type of malfunction | What does it lead to | External manifestation |

|---|---|---|

| Broken coil winding or internal wiring | Electrical circuit break | The lamp does not light (not even blinking) |

| Interturn short circuit | Loss of inductance, reduction of reactance | Burnout of lamp coils (including repeated after replacement), flashing without stable ignition |

| Short circuit to the body | In a network with a protective conductor, it creates a ground fault | If a PE conductor is connected, it causes overcurrent and triggers the protective device.If there is no protective grounding in the network, it may not manifest itself, but there is mains voltage on the instrument case. |

| Loss of ferromagnetic properties of the coil core (due to overheating, etc.) | Loss of inductance, reduction of reactance | Burnout of lamp coils (including repeated after replacement), flashing without stable ignition |

Verification methods

It is desirable to use devices to diagnose the condition, but if they are not available, the condition can be assessed without them.

Without tester

Verify throttle a fluorescent lamp is possible without a tester and other devices (at least an indicator screwdriver). But the reliability of these methods is limited.

- First of all, this is the behavior of the lamp. If, when voltage is applied, it blinks, but does not reach a steady glow, then there is a reason to check the throttle (although there may be other reasons, including a malfunction of the lamp itself). In the event of a break in the coil, there will be no blinking - the circuit will not show signs of life at all.

- visual inspection. If there is blackening, swelling, traces of local overheating on the throttle body - all this is a reason to doubt the health of the device. It must be replaced or diagnosed using instruments.

- Installation in a known working luminaire instead of a regular one. If after replacement the lighting device stops working, then the problem is in the throttle. Or, conversely, install a known-good choke in a non-working lamp. If the problem is solved, then the problem has been found.

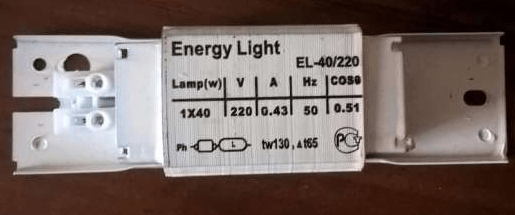

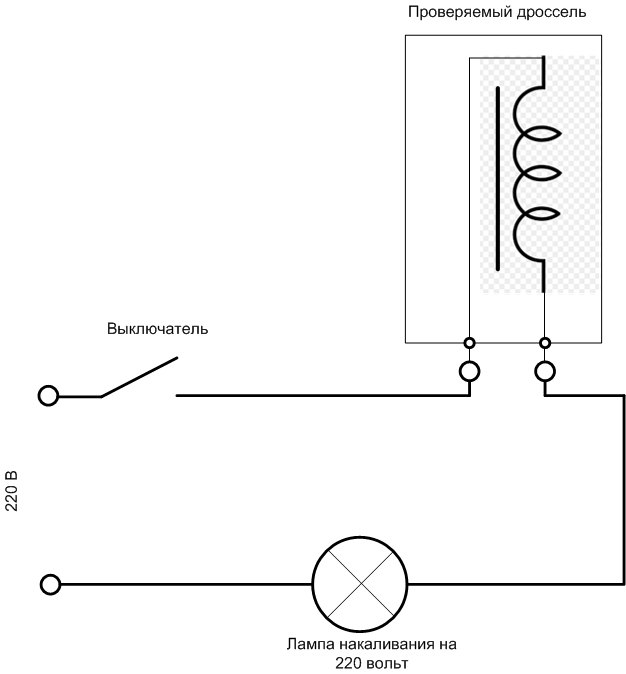

You can assemble a stand to test the elements of the ballast. This makes sense if you have to maintain the lighting system of a building, office, workshops, etc., built using fluorescent lamps. As a stand, you can take a ready-made lamp and replace standard parts with tested ones, or you can assemble a simple circuit. It uses a conventional 220 volt incandescent lamp.

To test the inductor of a fluorescent lamp, the properties of the inductive reactance of the inductor coil are used. Various situations are possible:

- the lamp burns out – the choke is serviceable, its reactance limits the current in the serial circuit;

- the lamp lights up to full brightness - interturn short circuit, the inductance of the coil is small, the reactive component of the resistance is close to zero;

- the lamp is off - a break inside the throttle.

Check the elements of electronic ballasts (electronic ballast) on such a stand will not work. It works on a different principle.

If a choke with a breakdown on the case is checked, then when power is applied to its case, mains voltage will be present. It is necessary to connect the ballast elements with the voltage disconnected. Observe precautions when supplying power.

With a multimeter

The multimeter provides more opportunities for checking ballast elements and the reliability of such testing is higher.

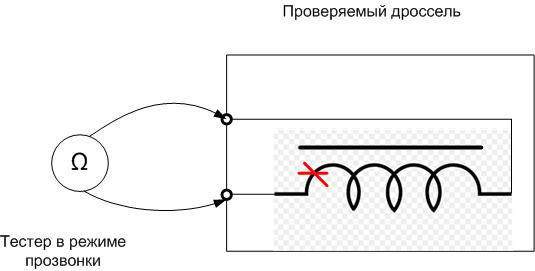

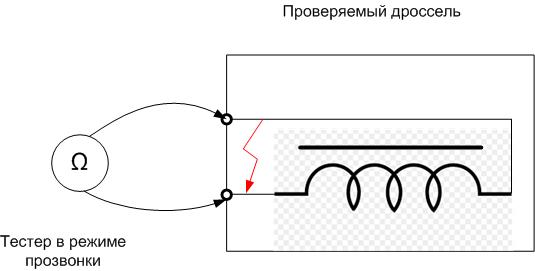

On the cliff

To check for an open circuit, a multimeter in resistance measurement mode (or sound continuity) must be connected to the ballast terminals. If the device is working properly, the tester will show a resistance of several tens of ohms (depending on the type of inductor, most common models have about 55..60 ohms).

If the circuit is broken internally, the meter will show infinite resistance.

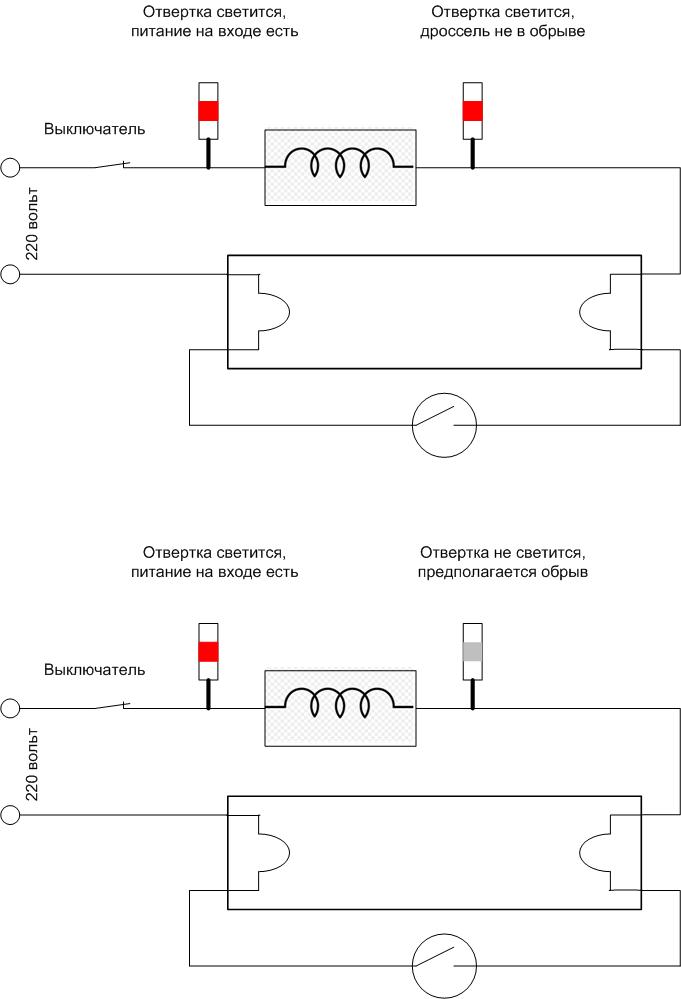

Also, the ballast can be checked for a break using an indicator screwdriver.This can be done without dismantling the device from the lamp, but only by removing the cover and supplying 220 volts (by turning on the light switch).

It is necessary to check the presence of voltage at the input of the throttle, and then at the output. If power comes to the input of the ballast, but it is not at the output, then there is a break in the throttle.

Read also: How to connect a fluorescent lamp correctly

short circuit

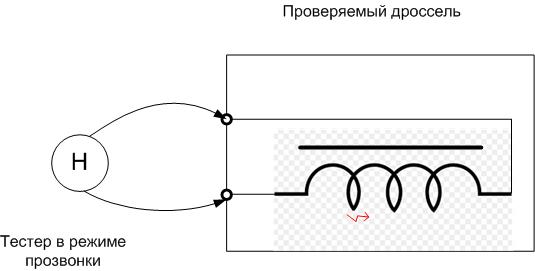

A short circuit is an infrequent malfunction. It can arise as a result of a global problem - sintering of coil turns, etc.

It is checked in the same way as for an open, but in the event of a malfunction, the digital device will show resistance near zero.

A much more likely problem is an interturn short circuit. It is almost impossible to detect it in the resistance test mode. If a small number of turns (2-3) are closed, the ohmic resistance will practically not change, and the inductance will drop sharply. Not every inexpensive multimeter has the function of measuring inductance, and even with sufficient accuracy. In addition, you need to know the inductance of a working device, and manufacturers rarely indicate this parameter. But you can try to compare the inductance of the tested ballast with the inductance of a known good one.

Also, a change in the parameters of the core (due to overheating, mechanical damage, etc.) can lead to a loss of inductance. And in this case, the fault is not easy to detect.

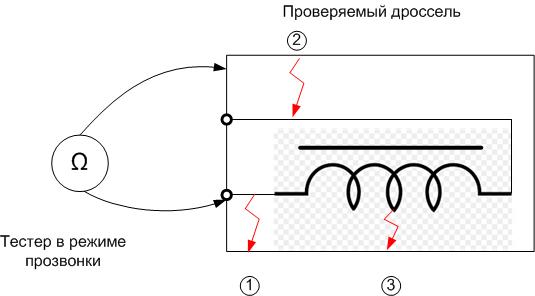

On the breakdown of the hull

To check for a breakdown on the case, one tester probe must be connected to the device case, the other to the ballast outlet (then to another).

If the inductor is good, the multimeter will show infinite resistance. If a breakdown is present, then either zero or some value depending on the location of the breakdown:

- if the short circuit occurred at point 2, then the tester will show the impedance of the coil;

- if point 1 is zero;

- at point 3 - some intermediate value.

Regardless of the location of the breakdown, the measured resistance will be less than infinity.

Conclusion

The traditional ballasts of fluorescent lamps are being replaced by electronic ones (electronic ballasts), and fluorescent lamps themselves are actively becoming a thing of the past - the time has come for the total dominance of LED lighting. But in the past, fluorescent lamps were popular, they are equipped with a large number of lighting systems, they are still produced today. Therefore, the issue of checking chokes for serviceability will be relevant for a long time.