Easy ways to connect LED strip

LED strip is a very popular lamp. With it, you can perform conventional lighting, you can make decorative or architectural lighting. To independently connect the LED strip, you need to understand a few points.

What you need to work

In general, you will need:

- the actual LED-lamp of the required length;

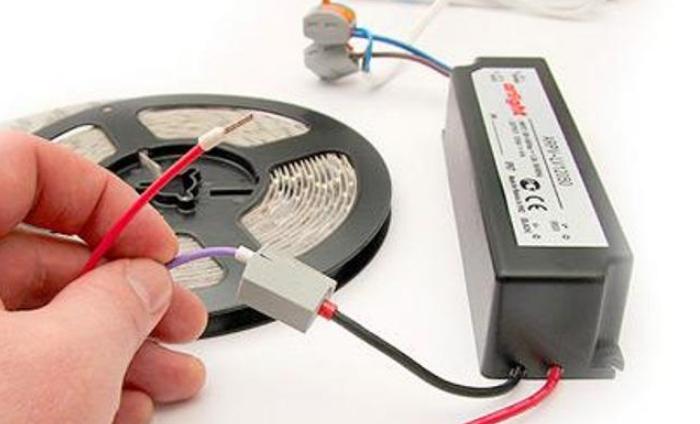

- power supply (or rectifier for 220 V tape);The power supply is selected with a power reserve.

- dimmer (if necessary);

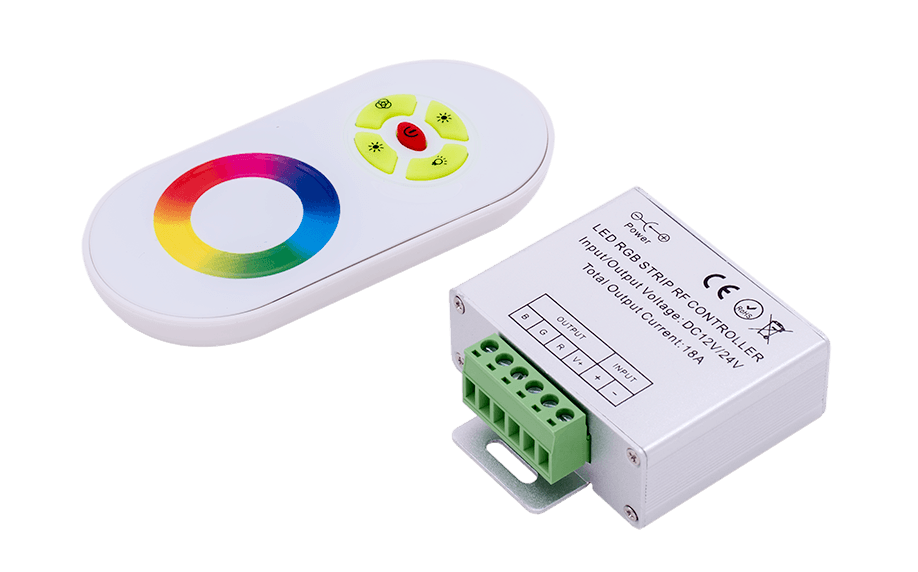

- RGB controller (for color tape);RF controller for 12/24 V and current up to 18 A.

- RGB amplifier (if necessary);

- connecting wires of the required section;

- power switch;

- connectors (although it's better to use soldering).RGB connector for direct connection.

This is a complete list, some items in a particular situation will not be needed.

Of the tools you will need:

- fitter's knife (for removing insulation);Knife for cleaning silicone coating.

- wire cutters (for cutting the necessary pieces of wire);

- scissors (for cutting segments ribbons).Scissors for cutting.

Instead of a knife, you can use a special insulation stripper. And if a soldering connection is selected, you will need a soldering iron with consumables.

Ribbon fastened on the adhesive layer, but to strengthen it or correct errors, it is good to have on hand:

- double sided tape;

- glue.

You can fasten the tape with plastic clamps, but this method, for aesthetic reasons, is only used outdoors. In this case, black ties should be used - white ones are not resistant to natural ultraviolet radiation and will not last long. It is categorically not recommended to fasten with furniture brackets - the risk of damage to the canvas and a short circuit is very high.

Calculation of the cross section of connecting wires

The cross section of the conductors should not be less than the permissible one - this leads to overheating and subsequent problems. Too large a cross section - to financial costs and inconvenience of installation. The current on the low voltage side can be calculated by knowing the total power consumed (Ptot) and operating voltage of the tape:

I=Ptot/Uwork

| Conductor cross section, sq. mm | 0,5 | 0,75 | 1 | 1,2 | 1,5 |

| Permissible current, A | 11 | 15 | 17 | 20 | 23 |

The current from the 220 V side is calculated by the formula I220=Inlow*(Utape/220V, where:

- I220 - current from 220 volts;

- Ilow – lamp current;

- Utapes – supply voltage of the lamp.

You also need to take a small safety factor for the efficiency of the power supply.

Important! For outdoor installation, the cross section of the conductors must provide not only the necessary economic current density, but also mechanical strength.

Power Supply Selection

The power supply has two main requirements:

- its output voltage must correspond to the supply voltage of the lighting device;

- power should supply the tape with a margin.

Power is calculated by a simple formula:

Rbp \u003d Rud * L * Kzap, where:

- rbp - the estimated power of the power supply, W;

- Rud - specific power consumed by 1 meter of tape, W;

- L – total length of the LED strip, m;

- Kzap – safety factor, taken equal to 1.2..1.4.

Important! As a result of the calculation, in most cases, you will get power that does not fall into the standard range of power supply power ratings. Round up to the nearest higher value.

You also need to select the version of the source:

- sealed - suitable for outdoor operation (it is not rational to use it inside - such modules need better conditions for natural cooling);

- leaky - usually installed indoors.

For non-hermetic ones, there are two options:

- with natural cooling;

- with forced ventilation.

The second option has smaller dimensions, but the fan makes noise. Therefore, it is not installed in rooms with the presence of people (apartments, offices).

The video talks about the main types of power supplies according to the degree of protection.

How to do without a power supply

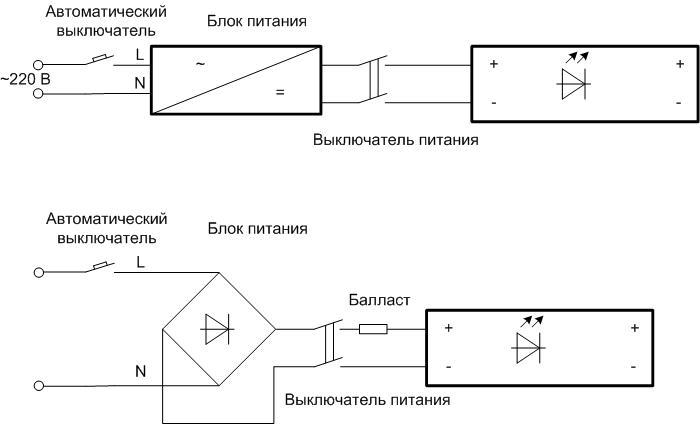

If it is not possible to install a power supply, there are two options:

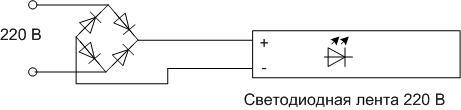

- use a tape designed for a voltage of 220 V;

- power a low-voltage lamp without a transformer through a ballast element that limits the current and extinguishes excess voltage.

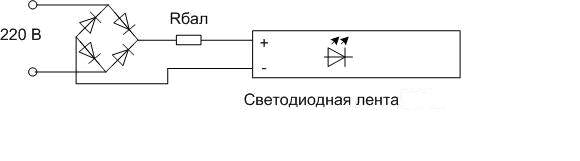

In the first case Do not directly connect the LED device to the AC mains. The LED, as a semiconductor device, will only pass the positive part of the sine wave. But during the negative, a reverse voltage will be applied to it, for which the LED or the chain is not designed. Therefore, the life of the lighting device will be short. Must be connected to a rectifier. Better over the pavement. The diodes must be capable of withstanding the full current of the tape and a reverse voltage of at least 320V.

This also applies to the second option, but an additional resistor will still be needed here. Its resistance is calculated according to the following method:

- The operating current is found by the formula I=Rud*L/Unom, where: Rud - specific power consumed by 1 meter of tape, W; L – total length of the LED strip, m; Unom – luminaire nominal voltage (12..36 V).

- The voltage drop across the ballast is determined Ubal=310-Unom, where 310 – amplitude value of voltage in the network.

- The resistance of the ballast is found R=Ubal/I. If the current is in amps, then the resistance will be in ohms.

- The power of the resistor is calculated as Рres = Ubal * I. The nearest higher value of the standard power series is taken.

The calculation is somewhat simplified, here the resistance of the LED in the open state is not taken into account. But for practice, the accuracy is sufficient.

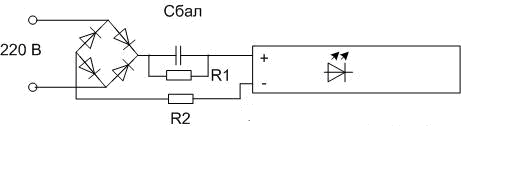

Instead of a resistor, you can install a capacitor. The advantage is that it won't get hot. Capacity calculation is performed according to the above formula:

C \u003d 4.45 * I / (310 - Unom), where:

- FROM is the required capacitance in µF;

- I - operating current found earlier;

- 310 - peak voltage of the network in volts;

- Unom – luminaire nominal voltage (12..36 V).

But additional elements will appear in the scheme:

- R1 - a resistor for discharging the capacitor after power is removed;

- R2 - to limit the inrush current on the charge of the capacitor at the moment of switching on.

The value of the first resistor is several hundred kilo-ohms, the second is several tens of ohms.

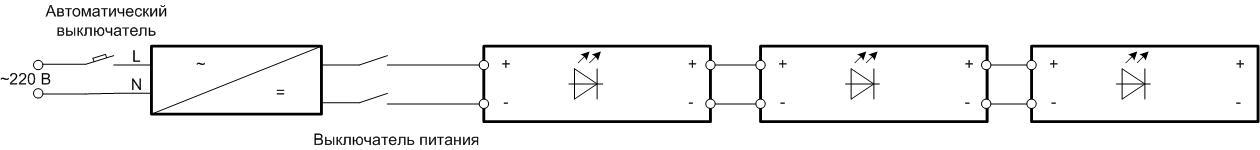

Connecting the LED strip to the power supply

The tape is connected to a voltage source with polarity - common terminal PSU (V-, COM) connected to the negative terminal of the lamp, positive (V+) to the positive. If an RGB tape is connected, then its common wire for all colors is the anode (+), and it is controlled by connecting the corresponding ruler to a common wire.

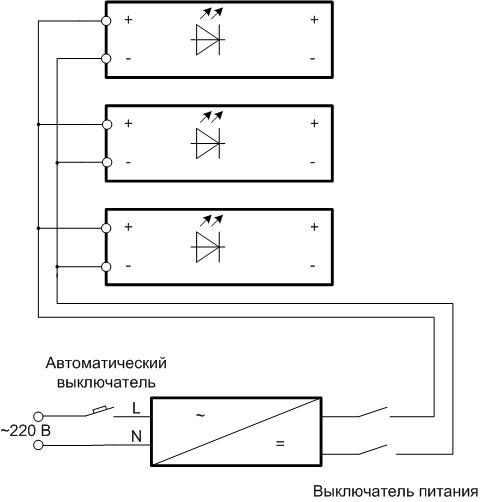

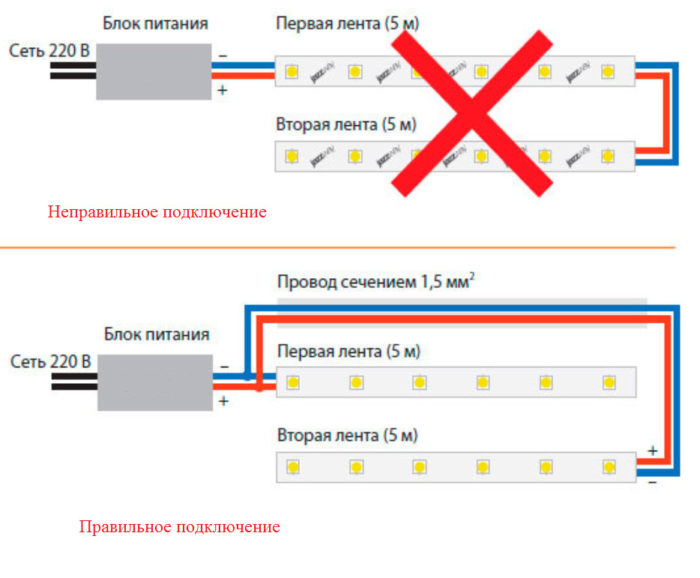

The lamp can be made in the form of a single piece of tape, or maybe in the form of several pieces of canvas. If the total length does not exceed 5 meters, segments of the tape (color or monochrome) can be connected in series (but they will be connected in parallel - this is the scheme) observing the polarity - plus to plus, minus to minus.

If the length exceeds 5 meters, then the lamp will consume significant current. The web conductors are not designed for high power transmission, therefore, even if a serious power source is used, the segments must be grouped in such a way that so that the total length of each group does not exceed the limit of 5 meters, and turn them on in parallel. To connect, use conductors (or connectors) of the required section.

Glow brightness adjustment

To adjust the intensity of the radiation of the LED lamp, a special device is used - a dimmer. It regulates the current through the LEDs by changing the brightness.

The connection of the dimmer is standard - to the input of a constant current source, to the output of the lamp, all with polarity. In most cases, the dimmer is combined with the power switch, so an additional switching element is not required. But the dimmers themselves come in different designs:

- Built-in with manual control. They are installed like household light switches, but have a rotary handle. By rotating it, you can adjust the intensity of the glow of the tape.

- Embedded with touch control and LCD display. They are also mounted like switches, but have a modern look and advanced adjustment options, including on / off timers, soft wake-up mode, etc.

- with remote control. They are controlled from the remote control via infrared or radio channel. In the second option, dimmers are marked RF, they can be hidden behind interior elements, and the glow can be controlled from the next room.

The dimmer has two important electrical characteristics by which it is selected:

- operating voltage (should match the supply voltage of the LED lamp);

- maximum load capacity (it is required that it withstand the operating current of the tape).

Unlike LED lamps, all LED strips are dimmable, because they do not have a driver (current stabilizer). The indication in the data sheet of "dimmable" (referring to the existence of non-dimmable products) is a marketing ploy. You can always connect any LED strip to a dimmer.

The need for switches

Even if the LED strip is supposed to be constantly lit, a power switch after the voltage source is necessary. In the case of repair or maintenance work (cleaning from dirt, etc.), it is convenient to remove the voltage with one movement of the switching element.

Important! If a transformerless connection of the luminaire is used, a switch must be used that disconnects both conductors at the same time.

There must be a circuit breaker on the 220 V side (regardless of the connection scheme). If the power supply or rectifier is plugged into a household outlet, then it is most likely protected by a machine. If a permanent connection is used, then it is imperative to provide for the installation of a circuit breaker. It serves as both a switching element and a means of protection in an emergency situation. And the installation of an RCD will never be superfluous, especially in the absence of galvanic isolation in the form of a transformer.

Video: Installing a non-contact flush-mounted switch for LED strip.

Controller for controlling color effects

RGB tape can be connected as monochrome. This is not economically feasible - a single-color lamp is much cheaper. You can connect it to manually control the glow - for example, using potentiometers. This is also not the best option. For the most complete access to the possibilities of a colored lamp, it is better to take an RGB controller that allows you to use the potential of the tape most efficiently.

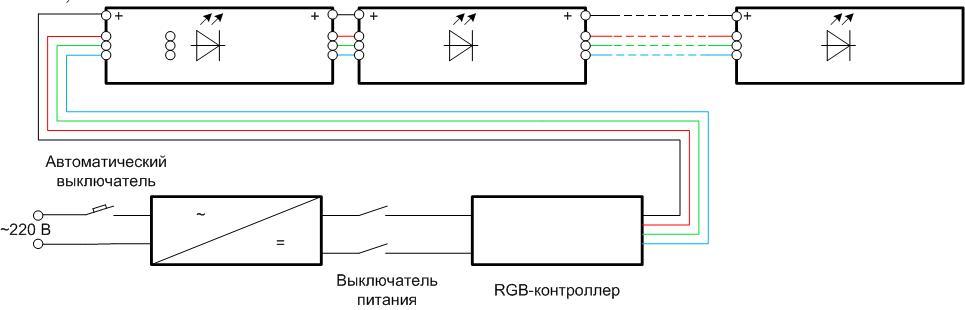

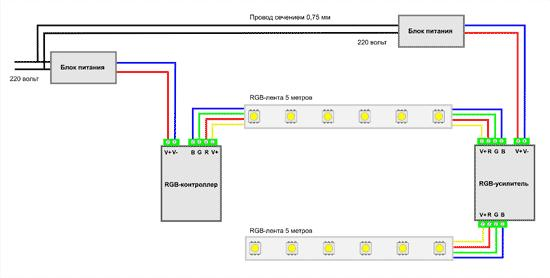

It is connected after the power supply, after it - pieces of tape with a total length of up to 5 m. Unite it is necessary in compliance with the pinout so that the contacts of the same color are connected to the corresponding contacts.

If you need to control a longer canvas, simply connecting groups of lamps in parallel will not always work. The power of the controller may not be enough, and you will have to use RGB amplifiers (in foreign technical literature - repeaters). One or more, depending on the load capacity of each repeater.

If the power of one power source is sufficient, then the second can not be installed.

This video review compares 4 types of controllers for a multi-color LED strip.

Connecting the tape is easy to do on your own, this will require minimal knowledge and skills. If the case turns out to be complex and beyond the scope of the review, a solution can be found by contacting specialists. You can find them in lighting companies or on the Internet in specialized forums.The main thing is to remember the safety rules.