We make lamps from pipe scraps with our own hands

Making a lamp out of PVC pipes or metal elements is much easier than it seems at first glance. You can assemble a modern stylish model in a couple of hours. For this, improvised materials are used: everything you need can be bought at almost any store. Components are inexpensive and a home-made lamp will cost several times or even tens of times cheaper than the finished version.

Features of working with PVC pipes

Plastic elements are notable for their low price, they can be found in all plumbing stores and buy the right amount. But in order to assemble a product with high-quality light that meets all safety standards, you need to remember a few simple tips:

- When choosing a material, take into account its dimensions and the properties of the plastic. If you have to bend the elements, the pipes must be well amenable to heating and forming.PVC elements are often welded using a special soldering iron.

- Plastic is afraid of high temperatures and can melt when overheated, so it is important to choose safe lamps for use in homemade lamps. Best fit LED or fluorescent types, as they heat up much less during operation.

- When using couplings and connectors, select all parts with the same diameter and the same thread pitch.

You can combine metal and plastic parts in one product.

Making a wall lamp from flexible metal-plastic

If after laying a water pipe, underfloor heating or heating, pieces of a metal-plastic pipe remain, you can use it to create a sconce. This is done like this:

- 3 or more light sources are used, cartridges are selected for lamps, it is better if they are small in size. You also need pipes from 25 to 50 cm long, wires and a base made from saw cut wood or a piece of plywood.

- Holes for pipes are drilled on the base, which can be fixed with adhesive, after which the wires are pulled. For convenient fastening of cartridges, you can cut out small elements from plywood or simply glue them to the sealant, after connecting the cable.

- After installing the lamps, shades of a suitable size are added from any improvised materials so that the light is directed to the right place.

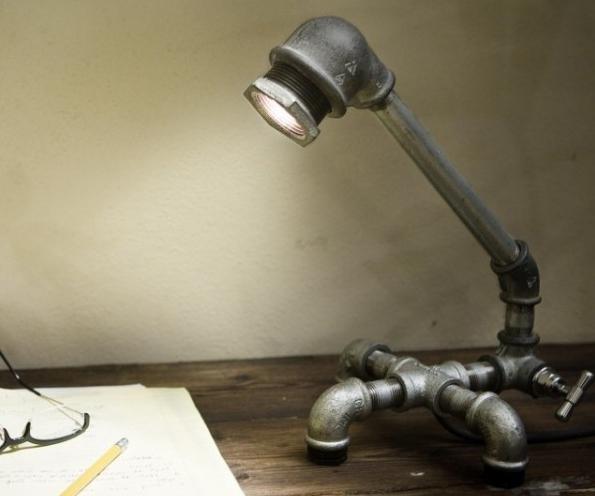

How to make a table lamp from muffs

If you have a lot of water pipe couplings on hand, you can make a stylish lamp. You may also need small pipe cuts and other fittings to make the equipment more convenient and attractive. Collect like this:

- The design of the product is thought out based on the details that are at hand. The easiest way is to make a sketch with approximate dimensions.

- All the necessary elements are prepared, usually you need to pick up pieces of pipe and cut threads on them. You will also need a wire, cartridge and lamp, or you can use LEDs.

- The assembly is carried out according to the scheme, it is important to lay the wire in advance where it is needed, so as not to disassemble the lamp later. For the ceiling, you can choose a suitable part or use a large-diameter sleeve that will fit the selected light source.

Do-it-yourself lamp from water pipes

It can be a lamp made of plastic pipes or a product made of metal elements, it all depends on the material that is at hand. Moreover, you can use both water and sewer options. Here the work can be carried out in different ways:

- To begin with, a sketch of the future product is made. You can assemble a desktop, wall or floor version, it is easy to find examples on the net and make your own model based on them. If pipes of different diameters are used (for example, 40 and 60 mm), the number of adapters that will be needed is calculated.

- The assembly should start from the base, a wire of a suitable cross section is immediately stretched and a power plug is placed.When connecting plastic elements without threads, it is best to moisten the seals with liquid soap in advance, then the fittings are easier to put on and the rubber elements are not damaged.

- Cartridges are usually fixed either with sealant or with small self-tapping screws that are screwed directly through the plastic. When using metal pipes, the connections should be tightened with a wrench so that they do not loosen over time.

[tds_council]A flexible multi-wire copper cable is great for connecting cartridges and sockets.[/tds_council]

Steampunk pipe lamp

It can be a lamp from a profile pipe or plumbing options. Metal elements are more often used, and anything is suitable for decoration: pressure gauges, gears, valves, chains and other parts from mechanisms. Also, aged or burnt wood will fit into the style. The build process looks like this:

- Thinking about product design. In this case, the wiring can run both inside and outside, if this option looks better. If necessary, a decorative coating is applied to the surface, imitating rust or giving an aged look.

- You can combine shiny and old details, the contrast looks good. When assembling, take into account the nature of use, so that the direction of light and the size of the luminaire ensure ease of use.

- If you need directional light, a ceiling lamp is selected in the appropriate style. And you can make a decorative frame from wire or strips of metal.

Must-see: Cool idea from a professional pipe.

How to make a hanging chandelier from pipes

Chandelier from pipes - an excellent solution for many modern interiors, which is easy to assemble on your own. Both metal and plastic parts are used for work, the instruction is as follows:

- The required power of the equipment is calculated, the suitable characteristics of the lamps and their number are determined. It is important to select sources with diffused light or pre-select ceiling lamps so as not to create visual discomfort.

- The design of the chandelier is being thought out, there are many options, the main thing is to choose the connectors of a suitable configuration and cut the pipes to size.

- For hanging from the ceiling, it is good to use a chain through which the cable is also pulled. Its size is selected according to the weight of the structure, it is important to ensure a secure fastening.

- If you are making a loft-style chandelier, you can use brass tubes and other parts, as this material fits well with the style. At the same time, brass can be varnished to add shine, or you can leave it as it is.

Video about the simple manufacture of a lamp in the LOFT style.

[tds_note]You can use unusual lamps to make the chandelier more original.[/tds_note]

The procedure for making a LED lamp from pipes

In this case, the lamp can be made in different ways, it all depends on the purpose of use and materials. The main options are:

- If you have a transparent pipe made of acrylic or other material at hand, you can lay inside it led strip and use the fixture as an independent lamp or a lamp in a chandelier. The main thing is to be safe to fix tape and connect it correctly.You can put an LED strip in a transparent tube.

- The second solution is cutting the pipe lengthwise and gluing the LEDs inside. To improve the reflective properties, the inner surface can be painted white or silver. Another solution is to stick foil, then the reflector will be almost as effective as in standard fixtures.

- The third option is to use a small diameter polypropylene pipe as the basis for winding the LED strip. It is attached in a spiral and covers the entire surface. Such a lamp is suitable for those who have ready-made lamps, but no light sources for them.

How to make an industrial style street lamp

If you need to assemble a lamp for outdoor use, you should follow a few recommendations:

- Use metal pipes and fasteners, and treat all threaded connections with a special compound to protect against water penetration and ensure easy disassembly if required.

- You can also weld the elements together, this is suitable if you use a profile to create a frame. At the same time, if the metal is located in the open air, it must be treated to protect it from corrosion.

- For plafonds, select elements suitable for style or make them yourself. Use frosted glass or translucent plastic as a diffuser.

Making a floor lamp from pipes

Floor lamp from pipes is another interesting solution that you can implement yourself. In this case, you need to think in advance about the color and style of performance, depending on the situation. The work is done like this:

- A base is assembled that will ensure the stability of the floor lamp. The height depends on the size and number of pipes used, they can be mounted both straight and with bends.

- It is best to buy a ready-made ceiling or make it from a wire frame and fabric from which the element of the desired size is sewn. And you can also use improvised materials - wooden blocks, metal containers, colored polycarbonate, etc.

A floor lamp can also be made with interchangeable shades to change its appearance if desired.

Video: Cool homemade polycarbonate transparent pipes.

What problems arise during the manufacturing process

During the implementation of the project, many difficulties can arise, the most common are:

- Different threads on fittings or their mismatch in diameter.

- Instability of the structure with a small size of the base.

- Difficulty mounting cartridges on thin pipes.

- Strong heating of the lamp in plastic structures.

- Poor insulation of the wire connection.

Master class: Divine lamp from ventilation pipes.

Assembling a craft from pipes is not difficult if you have the right materials at hand. The main thing is to comply with safety standards and securely isolate the wiring to prevent a short circuit. It is important to find a suitable model and choose the lamps of optimal power.