How to connect an LED lamp instead of a fluorescent

Should I change fluorescent light bulbs to LED bulbs?

The lighting market is massively filled with LED lamps of various formats, with characteristics that are attractive to those who like to save money. Given the increase in electricity tariffs, many manufacturers are speculating on this problem, promoting their products as eternal, efficient and at the same time economical. In reality, everything is not as rosy as marketers and replacement paint. fluorescent lamps on LED will be beneficial if you purchase very expensive devices. The properties attributed to the LEDs correspond to the products of branded lighting manufacturers. As a rule, the cost of their products rolls over, nullifying all the benefits of re-equipment. This is how, in the understanding of the manufacturers of LED-elements, the comparative characteristics of their products with fluorescent lamps look like.

By and large, with a certain combination of devices, the presented characteristic is true, since there are bad fluorescent and good LED lamps. The key factor determining the effectiveness of a particular lamp is the price. But if we take the average range, then everything looks a little different.

Is there any savings in this?

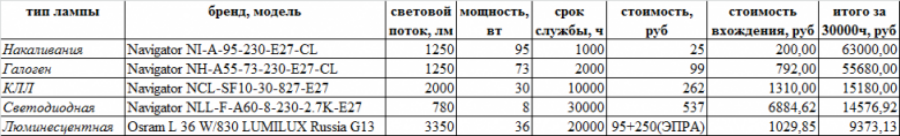

According to the passport data of specific models of lamps from one manufacturer, it is possible to calculate the cost of the lamp for a certain period of time. In the case of Navigator and Osram, the calculation table looks like this.

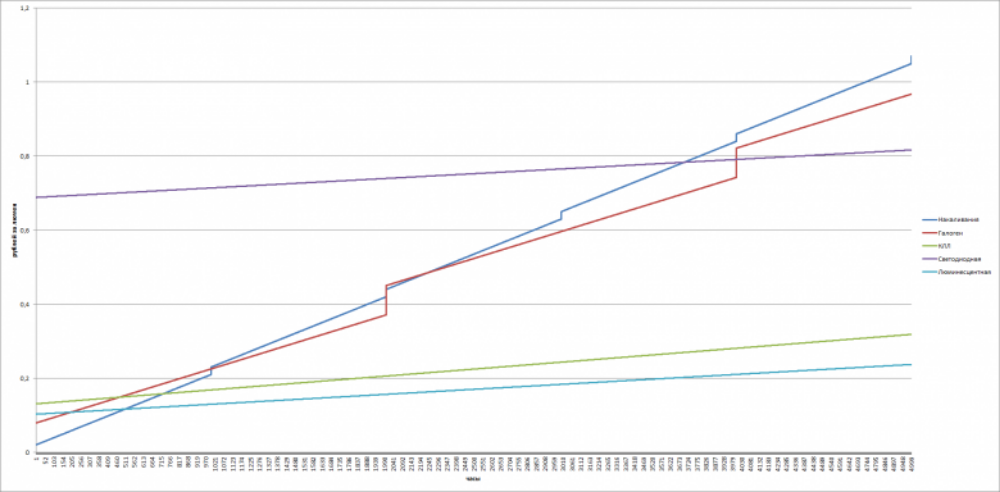

Based on the calculations, the most expensive of the presented devices are incandescent and halogen lamps. The cost of LEDs is comparable to gas-discharge housekeepers, but fluorescent lamps, even with a power of 36 W versus 8 W for LED lamps, are cheaper. LED lamps begin to pay for themselves only after 4,000 hours, and become more profitable than energy-saving ones after 25,000 hours of operation, as can be seen on the graph.

In fairness, it should be noted that the service life of branded LED elements of 50,000 hours allows them to be oriented towards the long term, while fluorescent will have to be replaced already after 20,000-30,000 hours.

Differences at work

With the possible external similarity of T8 light sources, fluorescent and LED lamps work according to different principles. The fluorescent light source is a glass flask filled with mercury vapor. When a high-frequency voltage is applied to the electrodes, mercury ions emit light in the ultraviolet range.To convert ultraviolet light into the spectrum visible to the eye, a special phosphor is sprayed onto the inner surface of the glass bulb, which glows under the action of UV rays in the visible range. Hard ultraviolet is not passed through. To start gas discharge, a throttle with a starter is required.

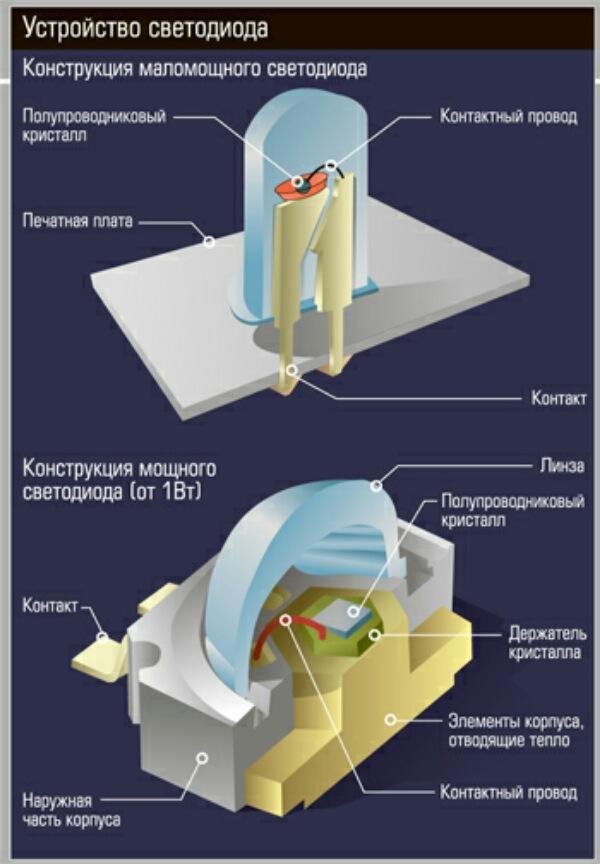

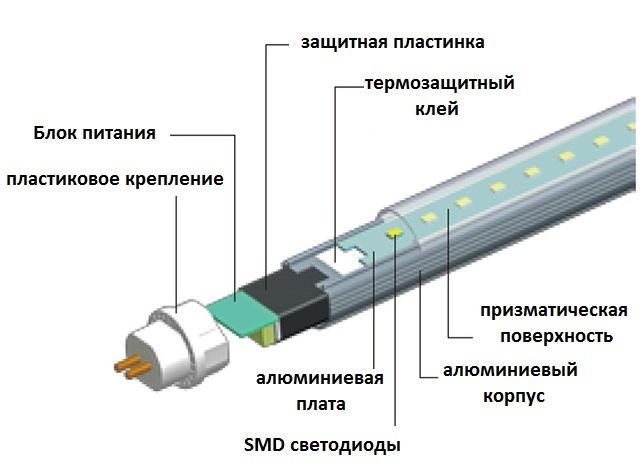

The LED element glows due to the passage of a low power current through the crystal in the glow range specified by the manufacturer, mainly in cold tones from 5,000 to 10,000 Kelvin. To start the LED lamp from a 220 V network, a driver or electronic ballast - electronic control gear.

The advantage of LED lighting in fixtures

LED lamps are installed everywhere instead of fluorescent ones, since, other things being equal, they win in some respects:

- environmental friendliness Fluorescent lamps contain toxic mercury. In this regard, the disposal of gas discharges in the usual way is prohibited. The regulation prescribes the delivery of used flasks to a special enterprise, and the cost of disposal is from 8 rubles per unit. The LED element can simply be thrown into a container for municipal solid waste; if the structure is destroyed, it does not pose any danger to others;

- light output and performance - although most manufacturers claim an efficiency of LED lamps of 90%. In fact, this figure is close to 40%. Taking into account the losses of electricity in the driver, the efficiency of the LED lamp is reduced to 130 lumens per watt, which is 25-30%. However, even taking into account all the deductions, luminescent devices lose even here, since their maximum efficiency does not exceed 80 lumens / watt - 20%.Given the lack of developments in this direction, no further improvements are expected in terms of gas discharges;

- ergonomics - the operation of fluorescent lamps and ballasts is accompanied by a buzz, crackling, radio and audio interference for nearby electrical appliances. In addition, the pulsation coefficient of the light of gas discharges at the time of their launch exceeds 20% versus 5-10% for LED lamps;

- stability - during power surges in the network, especially when it drops to 180 volts, the fluorescent lamps blink or go out. Cheap Chinese LED devices with a diode bridge instead of a voltage stabilizer also do not work correctly. But the use of high-frequency regulators in the circuit solves this problem;

- degradation - the phosphor crumbles and burns out over time, reducing the light output and shifting the gas discharge glow spectrum to the dangerous ultraviolet range.

The main disadvantage of LED lamps is the price, still exceeding gas-discharge analogues. The increase in affordability comes at the expense of circuit simplification and the use of inefficient parts, which eliminates some of the benefit of retrofitting to a new type of lighting instead of obsolete fluorescent tubes. Chinese products often do not last longer incandescent lamps, get very hot, burn out, so their operation is even more expensive due to the forced replacement of the light source after it breaks down.

Rework order

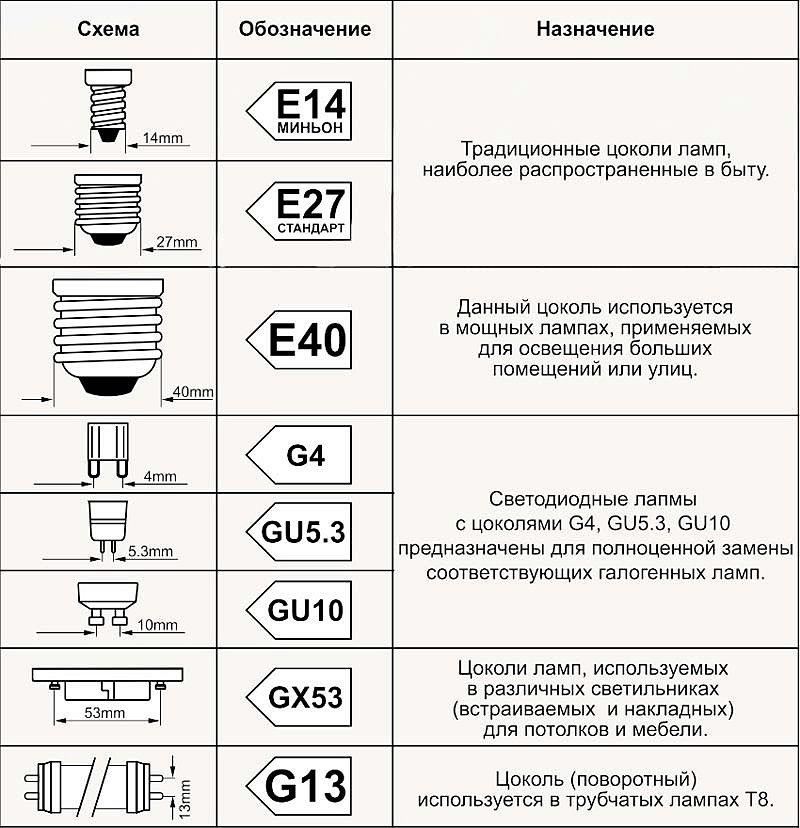

If replacing an incandescent lamp or a housekeeper with an E27, E14 base with an LED of the same format and dimensions is not difficult, then installing a T8 format lamp with a G13 base already requires some adjustments in the device of the original lamp.

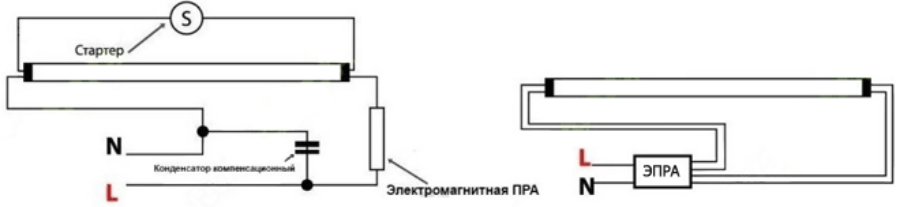

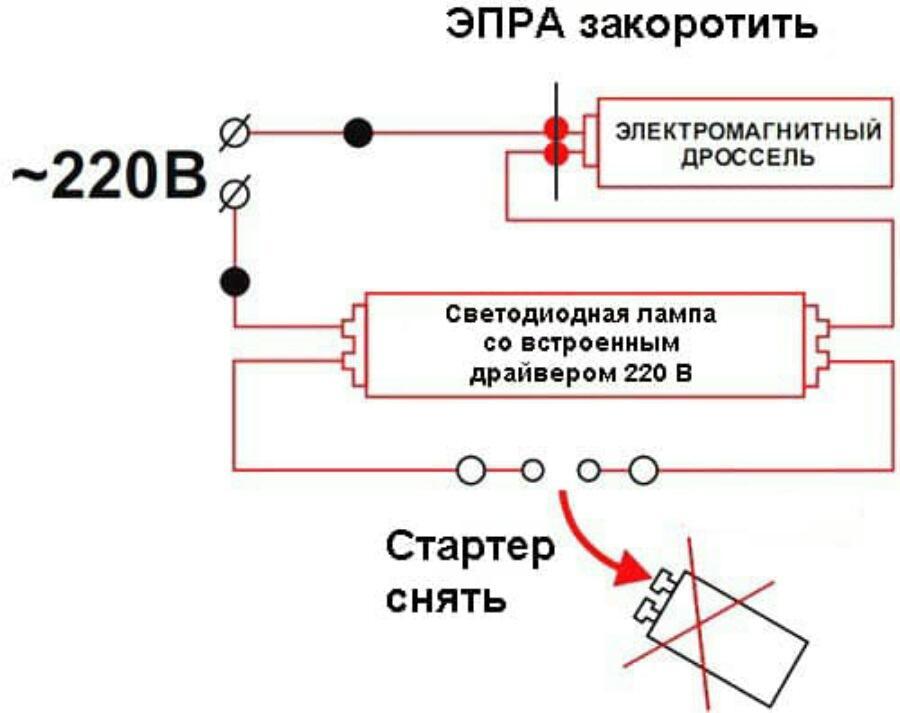

To start gas discharge, an electronic ballast or a choke with a starter is used, and these elements must be excluded from the circuit.

How to install LED lamp instead of daylight directly

The connection diagram of a tubular LED lamp does not have additional elements, since a driver for starting is already installed in its housing.

The T8 LED tube format corresponds to a daylight bulb 600, 900, 1200, 1500 mm long. Depending on the manufacturer, there are two types of their connection:

- Phase and zero are fed to two contacts on one side.

- Phase and zero are located at opposite ends of the tube.

The second type is more common. At the same time, if a filament is installed between two pins in the gas discharge to preheat mercury vapor before starting, then in the LED tube of the second type, the contacts are interconnected by a jumper. In the tube of the first type, the jumpers on the unused side perform a fastening function. To convert a daylight to a new type of light source, you must:

- Turn off the power supply at the circuit breaker.

- Remove lamp housing.

- Remove old glass flasks.

- Remove the protective cover to access the internal circuitry.

- Remove the throttle, starter, electronic ballast by disconnecting them from the conductors or bite the wires with wire cutters. These design elements are not needed.

- Remove all unnecessary wires, leaving only two going to the cartridges on the body.

- Connect opposite cartridges directly to phase and zero.

- Connect the two outgoing wires to the plug, install the LED tubes and make a test run.

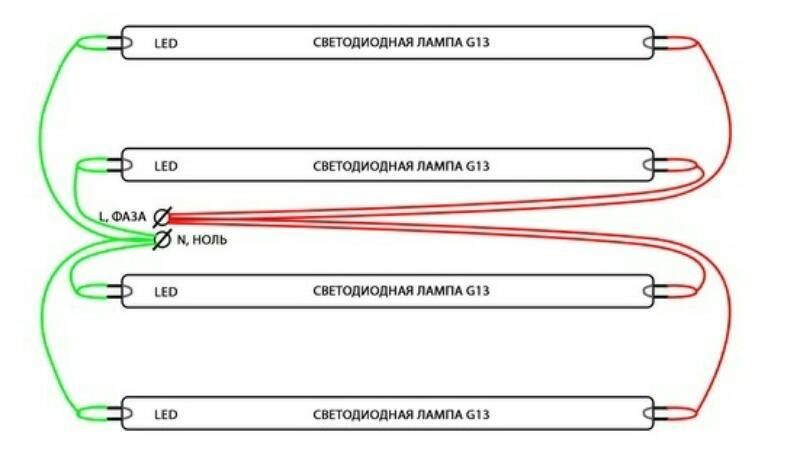

On the G13 cartridge, you can install a jumper between the paired contacts, but this is not necessary, since the presence of a jumper on the lamp itself guarantees contact when voltage is applied to one of the pins. If the cartridge is installed so that the contacts are arranged vertically, and the design of the LED tube does not have a rotary mechanism, then the cartridge must be moved to a horizontal position. To do this, you will have to drill mounting holes for the bolts and screw the cartridge in a different position. If several tubes are installed in the luminaire, then the lamps are also connected directly by parallel connection.

It is desirable to bring a separate pair of wires to each pair of cartridges. The inductor or electronic ballast can not be removed, the main thing is to disconnect them from the circuit, but their weight greatly complicates the design, and in the future they may be useful for repairing other devices. It is possible to remake by removing the starter and disconnecting the throttle with the installation of a jumper instead of the electronic ballast, as in the figure.

A detailed overview of the lamp upgrade is presented in the video: