How to make a solar panel at home

A do-it-yourself solar battery is much easier to assemble than many people think. To carry out the work, you do not need to be an electrical engineer; tools are used that can be bought for little money. The main thing is to understand the topic well, make a detailed diagram and buy high-quality components.

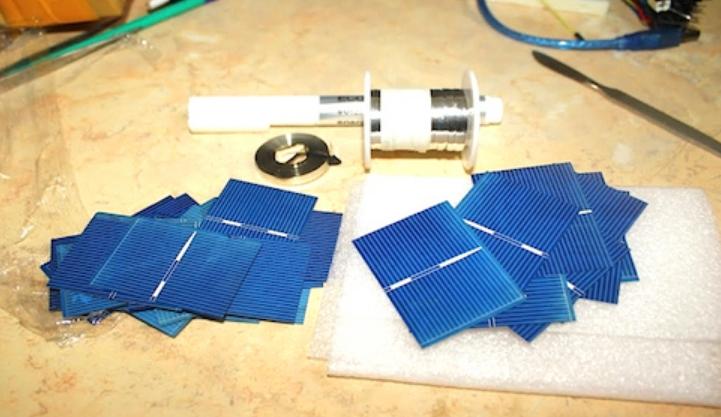

Which photocells are suitable and where can I buy them

First of all, we need to consider what types of photocells are currently being produced and understand their features:

- Monocrystalline silicon panels are made from the highest quality ingots.Thin plates are cut in them, which have a long service life - up to 50 years and an efficiency of about 19%. But the price of this decision is the biggest.

- Polycrystalline modules are made of lower quality silicon, but have a good efficiency of 15%, which, with a service life of 25 years, makes this option optimal in terms of price-quality ratio.Polycrystalline options are best suited.

- Amorphous modules are distinguished by the fact that silicon is deposited on a flexible base. This makes the sheets light and inexpensive, but in terms of service life and performance they are worse than the first solutions.

Homemade options are always inferior in efficiency to factory solar panels. This happens for a number of reasons - from the accuracy of calculations and the quality of parts to the inability to purchase some components separately. But if you choose the right type and do the work according to the instructions, you can get a high-quality and efficient module.

There are no film options on sale, so you will have to choose between monocrystalline and polycrystalline products. The second type is cheaper, so it is used more often.

Project preparation and location selection

It is not difficult to make the simplest homemade battery circuit, for this you need to take into account a few points:

- Required power. Calculated based on energy consumption. You can cover only part of the needs, increasing performance over time, or you can immediately install as many panels as you need for complete autonomy.

- The number of photocells and accessories for them. It is better to calculate in advance in order to order everything you need and not wait weeks for the delivery of the missing part.

- It is worth considering in advance the design of the frames and the fastening system, they must ensure reliability. It is important that in strong winds the solar panels do not tip over and fall, as they will be damaged.

The location is chosen so that the solar panels receive light for most of the day. Most often, batteries are placed on roof or on the ground. It is important that no shadow falls on the surface. The angle is selected depending on the region, in the middle lane the optimal indicator is from 50 to 60 degrees. For the winter period, you can increase the angle to 70, and in the summer, reduce it to 30-40 degrees.

Construction assembly

A do-it-yourself solar panel is assembled in several stages. It is best to do the work in order so as not to miss anything and achieve a good result.

Frame manufacturing

The basis for future solar cells must be strong and durable, it can be made from different materials. You can use moisture resistant plywood or OSB boards, in this case the work is carried out as follows:

- Pieces of a suitable size are cut out, a frame is made of a wooden bar around the perimeter, it is important to precisely fit all the parts to each other so that there are no gaps, and grease the joints and joints with a weather-resistant sealant. Then the surface is covered with a protective compound or paint and left to dry completely. It is better to apply the coating in several layers.

- Use an aluminum frame as it is much stronger and more durable than wood. In this case, the corners are selected and connected to make a solid frame. Plexiglas or other transparent material is placed in it, all joints must be treated with a sealant so that there are no gaps. You can continue to work after the composition is completely dry, the excess can be cut off with a construction knife.Product sealing is required.

By the way! The dimensions of the frame are selected according to the parameters of the purchased photocells. While they are not, it is better not to make frames.

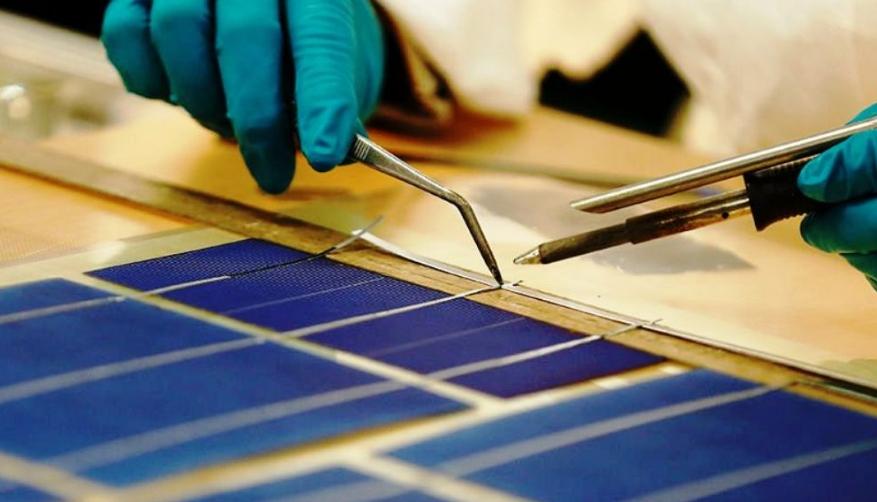

Soldering wires and connecting photocells

All modules have contacts that have different polarities; before starting work, they are wiped with alcohol, after which conductors are soldered to them. Only then can they be combined with each other to assemble the system. If the conductors are already soldered, all connections must be checked, often there is a defect that must be corrected before installation. If special tires are used, then the instructions for the work are as follows:

- Tires need to be cut into strips of the appropriate size if they come in one sheet. The contacts on the plates must be wiped with alcohol for degreasing, after which a small layer of flux is carefully applied to them.

- The tire should be applied to the contact along the entire length, after which a heated soldering iron should be drawn over the surface without pressure so as not to spoil the panel. After cooling, the element is turned over and the work is repeated on the contact from the second side in the same order.You need to solder very carefully.

- To correctly place the connections and select the appropriate length, first lay out the modules on the prepared base and mark their position.

- It is not so difficult to prepare a solar cell with your own hands. After the pins are attached, the modules are put in place and connected together. The main thing is to follow the observance of polarity.

If there are irregularities on the connection of the bus with the contact, it is necessary to draw the soldering iron over the surface again.

Application of sealant

At home, it is easiest to use building weather-resistant compounds, which are sold in all stores. The work is done like this:

- First, you need to apply drops of the composition along the edges of the photocells after a short distance. After that, they are placed on a transparent base according to the marks made earlier. It is important to line up the modules and press them as tightly as possible to the surface.

- To fix in a suitable position, any weights are placed on the places where the sealant is applied. They can be removed after the composition has dried.

- Next, you need to cover all the edges with sealant, as well as the joints between the elements, in order to completely seal them. It is important not to get on the working parts.

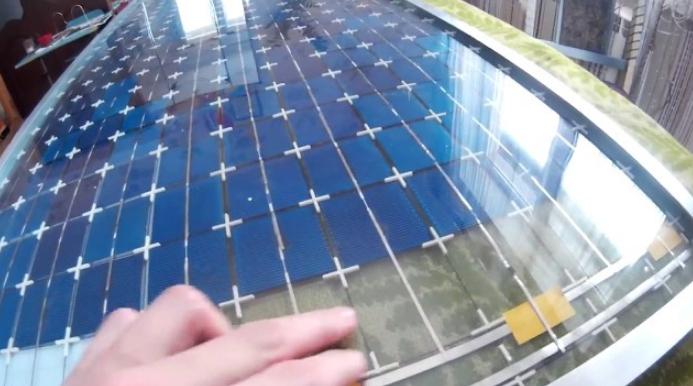

Panel Assembly

When the sealant has dried, you can carry out the final assembly. There may be some peculiarities depending on the system, but most often the process looks like this:

- First of all, a connector for connection is attached to the side of the case, to which Schottky diodes must be connected.

- A screen of transparent material is cut out on the outside, which is best fixed on a sealant to ensure the tightness of the structure and prevent moisture from entering inside.

- The finished item is checked for performance. If everything is fine, you can put it on the mount frame to install the battery in the prepared place.

How to make a power supply from improvised materials

You can assemble the simplest battery from improvised elements. There are several options, the most popular are:

- A piece of copper foil is taken and heated on an electric stove for half an hour, after cooling, an oxide film is removed from the surface. A second piece of the same size is cut out, both elements are slightly bent and placed in a cut bottle or jar so that they do not touch each other. Crocodiles are attached to the edges, salt water is poured into the container, after which the generation of current will begin.

- If you have a lot of unnecessary transistors on hand, you can extract semiconductors from them and assemble a solar battery. The assembled elements are placed on the plate and connected, after which the wire is connected and the system can be used. This option will not give a lot of energy, but it will be enough for the radio to work and charge the phone.

- You can make a power source from diodes, for this you need to open them to open the photocell. To remove, the element is heated to melt the solder. The extracted crystals are soldered to the body and connected to the system.

- From beer cans, you can assemble a structure for heating water or air.To do this, the upper part is cut out in them, a hole is made in the lower one, the container is well washed. Then a large box is made of a wooden block and polycarbonate. Banks are placed in rows and connected with sealant. After painting the surface black, you can put the module outside.

Banks are easiest to press with long plates or bars placed every 50-80 cm.

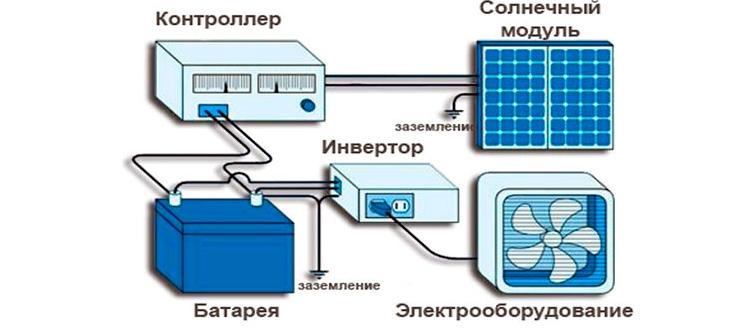

Installation and connection of the solar battery

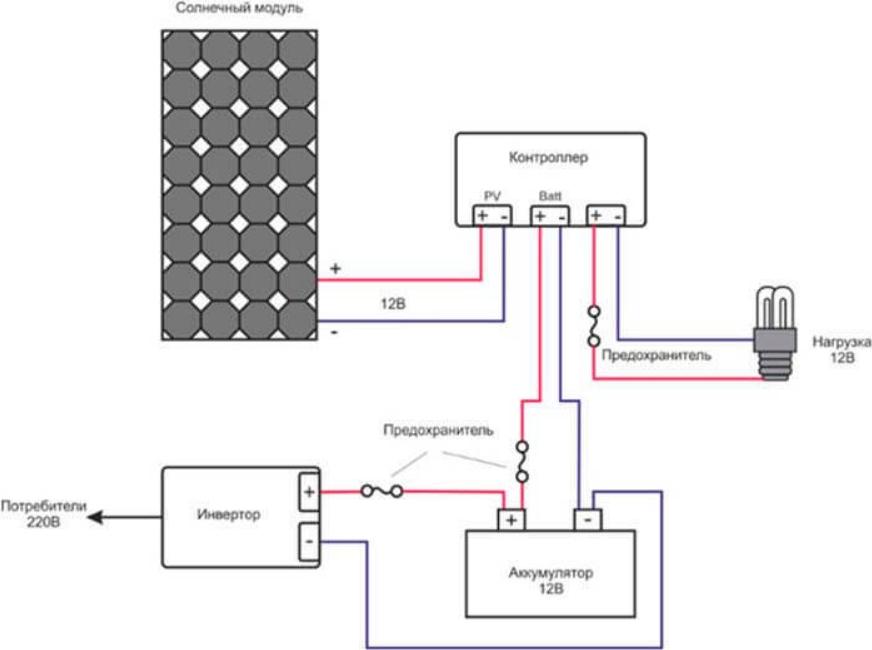

Once the battery is installed, it must be connected correctly to ensure efficient power consumption and conserve electricity when not in use. It's simple:

- The controller is connected to the module, it is desirable to place it as close as possible.

- Batteries are placed in a specially designated place. It is better to use gel.

- To convert the voltage, an inverter is required.

Everything here is similar to systems with ready-made batteries, so you don’t need to understand the topic.

What affects the efficiency of solar panels

To achieve the maximum effect, you must follow these simple tips:

- Put the batteries in a place with the best lighting during the day.

- Periodically wash the protective glass from dirt and dust.

- Adjust the angle of inclination depending on the season.

- Use an inverter with suitable power.

- Monitor the status of contacts and connections.

When lenses are used, battery performance is greatly reduced in cloudy weather.

Which is better - buy or make a solar battery

There is no single answer here, it all depends on the budget, the required system parameters and the cost of each of the options.It is best to make a comparative analysis of both types in order to compare the material and time costs for each of the types.

Usually, making your own hands is half the price, so if you need to save money, it is better to choose a home-made type. If there are no budget restrictions, it is better to use ready-made systems.

Detailed video assembly instructions from the popular KREOSAN channel

It is not difficult to assemble a solar battery with your own hands, if you understand the design features, calculate the required number of modules and buy them in advance. It is important to follow the assembly instructions and ensure the tightness of self-made modules.