How to make an LED lamp

Craftsmen often want to make a diode light bulb, at least for the reason that it saves 10 times more electricity when compared with an incandescent lamp. This is extremely cost effective. But for self-assembly, experience in working with lighting circuits is required.

First, you should familiarize yourself with the principle of operation of the LED lamp and find out what varieties of it exist. After that, you can begin to select the necessary materials and tools. In order for the light bulb to last a long time, it is better to buy only high-quality structural elements.

The principle of operation of the LED light bulb

The operation of LED lamps is based on the action of a semiconductor with a size of 1-2 mm. Inside it, there is a movement of charged elementary particles that convert the current into a direct current from an alternating one.However, the chip crystal has another type of electrical conductivity - negative electrons.

The side with the fewest electrons is called the p-type. The other, where there are more particles, is "n-type". When they collide, particles of light, photons, are generated. If the system is energized, the LEDs will continue to emit a stream of light. All modern LED bulbs work on this principle.

Types of LED devices

The type of a particular lamp is determined depending on the location of the LEDs:

- COB. The LED is soldered into the board. This will increase the intensity of the glow and protect against overheating;

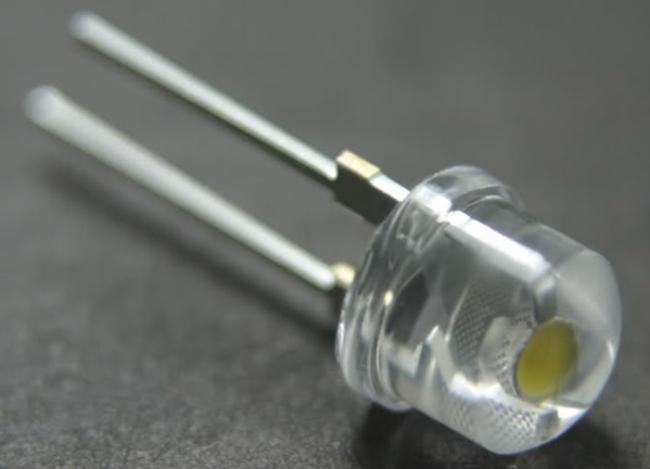

- DIP. Here the crystal is connected to two conductors, and an magnifier is installed above them. The modification is used in the production of garlands and advertising banners;

- smd. To improve heat dissipation, diodes are mounted on top. Due to this, it is possible to reduce the dimensions of the light bulb;

- "Piranha". We are talking about ultra-bright light-emitting diodes with increased protection against vibration. In most cases, they are installed in cars, as they are characterized by reliability.

The most significant drawback is the COB design. If at least one chip fails, it will not be possible to replace it, you will have to change the mechanism completely or buy a new lamp.

What materials are needed to make

To assemble a light bulb, you need to buy the following structural elements:

- frame;

- LEDs (individually or mounted on a tape);

- rectifier diodes or diode bridge;

- fuses (if there is a burnt unnecessary lamp, they can be removed from it);

- capacitor.The capacity and voltage must match the number of chips and the wiring diagram;

- if you have to make a frame for installing chips, you need to purchase a heat-resistant material that does not conduct current. Metal will not work, so it is better to buy thick cardboard or durable plastic.

Of the tools for work, you will need pliers, a soldering iron, scissors, a holder and tweezers. You will also need liquid nails or glue to mount the LEDs if using cardboard.

Schemes of LED lamps

Before you start assembling an LED lamp, you need to choose one of the possible schemes. There are several options, all of which have their own advantages and disadvantages. It also depends on the purpose of the lamp. One of the most common circuits includes a diode bridge and 4 LEDs.

LED element

If the house has a broken LED lamp, you can take the missing parts from it. But before rearranging any elements, it is necessary to check them for correct operation using a 12V battery. Damaged parts should be removed. To do this, you need to take a soldering iron and unsolder the contacts, removing the burnt diodes.

Do not forget about observing the alternation of cathodes and diodes mounted in series. If 2-3 chips are being replaced, they can be soldered to the same areas where the burnt chips were. Next, about 10 diodes are installed in a row, observing the polarity. You also need to make sure that the soldered ends do not touch each other. Otherwise, when turned on, it will cause a short circuit.

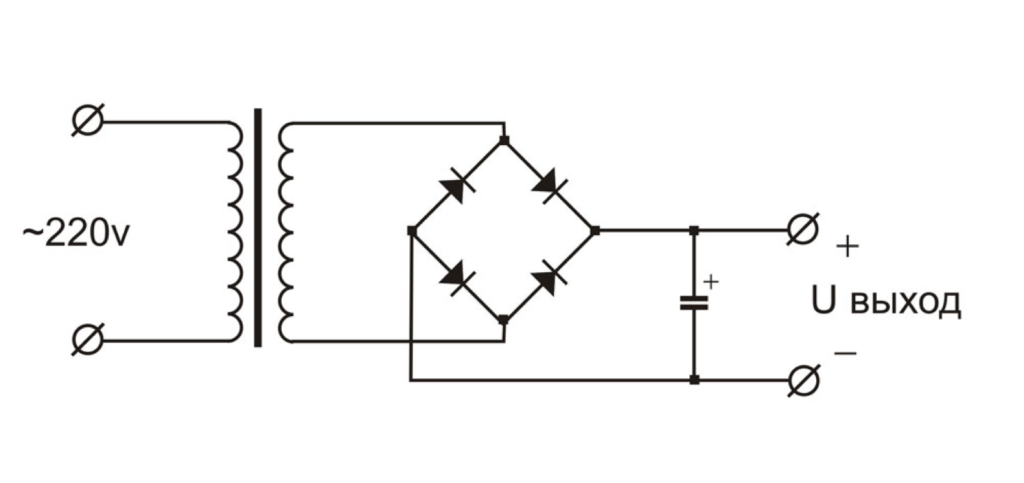

Scheme of a converter with a diode bridge

As mentioned above, the circuit includes 4 LEDs that are connected in different directions. That is why the bridge can transform the 220V current into a pulsating one. A similar thing happens in the process of crossing over 2 chips of sine waves.

Polarity is lost due to their change. During the assembly process, a capacitor must be connected to the output with a plus in front of the bridge. Another one should be behind the bridge. It will perform a smoothing function during voltage drops.

Schemes for a softer glow

If the master is faced with the task of getting rid of flicker, which is characteristic of almost all LED bulbs, several additional elements must be included in the circuit. In general, it should include capacitors, resistors and a diode bridge.

To protect the lamp from power surges in the network, a 100 Ohm resistor is installed at the beginning of the circuit, after which there is a 400 nF capacitor, then a bridge is mounted, followed by a resistor. The last in the chain include LEDs.

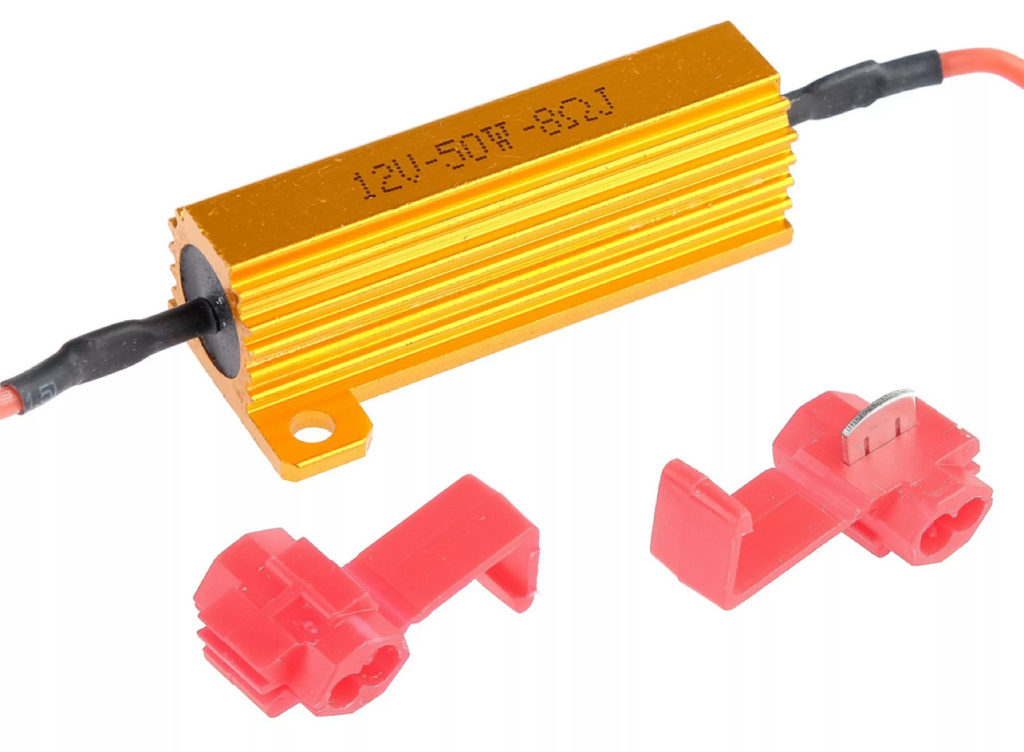

Resistor circuits

This scheme is quite affordable even for beginners. To assemble a device based on it, you need to buy 2 12k resistors, as well as a pair of circuits with the same number of chips soldered in series, taking into account the polarity. One strip of diodes from the side (R2) is connected to the anode, and the other (R1) to the cathode. Devices that are assembled according to this scheme are distinguished by soft light, since at the moment of switching on the LEDs light up alternately.

Due to this effect, the ripple is practically invisible to the naked eye. Such a light bulb is best suited for a table lamp.To get optimal lighting, it is recommended to purchase tapes with 20-40 diodes. If there are fewer of them, this will give an insignificant luminous flux. But the more elements, the more difficult the work in technical terms.

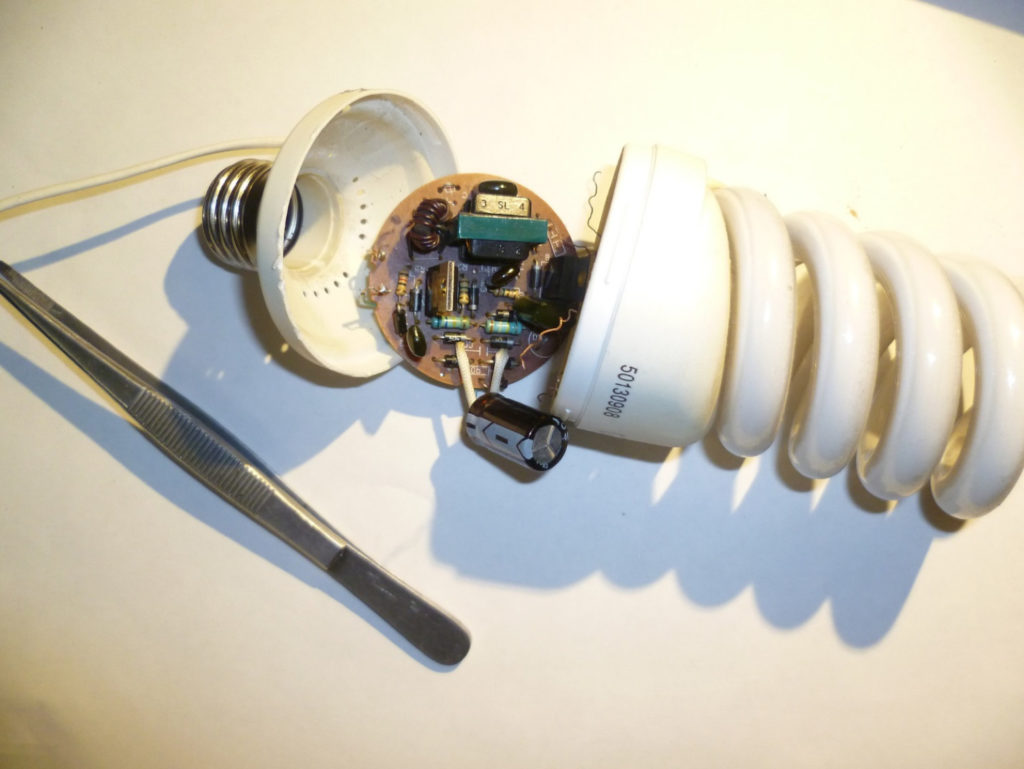

Manufacturing steps

The assembly will be considered based on a standard fluorescent lamp base. The first step is to disassemble the lamp. All luminescent devices are connected to the base with latches through a plate with tubes. Here the task of the wizard is to find the attachment points and disconnect the base with a knife or a flat screwdriver.

In the process of disassembly, you should be careful not to accidentally damage the tubes that contain toxic substances. Also, do not damage the wiring connected to the base. The upper part with tubes is used to make a plate for installing LEDs. To do this, the tubular elements must be removed.

In the next step, you will need a plastic or cardboard cover, it will serve to insulate the LEDs. For example, if HK6 diodes are installed in the lamp, each of them has 6 crystals connected in parallel. With minimal energy consumption, they will give the brightest light possible.

To connect each of the chips, 2 holes should be pierced in the plate according to the chosen scheme. On this material, the diodes can be fixed as firmly as possible, so thick cardboard should be used only in extreme cases. But if there are no other options, LEDs are attached to the base with superglue or liquid nails.

According to the given example, the device is designed for 6 chips with a power of 0.5 W, therefore, elements connected in parallel should be included in the circuit. In a light bulb operating from 220 volts, you need to install a driver. At this stage, it is important to isolate it from the payment using cardboard or plastic to avoid a short circuit. There is no need to worry about overheating, as this lamp practically does not heat up.

The next step is to start assembling. Light bulbs powered by a standard cartridge and a 220V network are characterized by low power consumption and power up to 3 watts. The assembled lamp has luminous flux characteristics from 100 to 120 lm. But thanks to the white light, it seems bright. The product is suitable for lighting a pantry, corridor or installation in a table lamp.

Choosing a lamp housing

The case should be decided even before choosing a scheme. In this case, you can use several options:

- base from an incandescent lamp;

- self-made device;

- using a housing from a halogen or energy-saving lamp.

Masters prefer the latter option, as it is the easiest.

Energy saving lamp housing

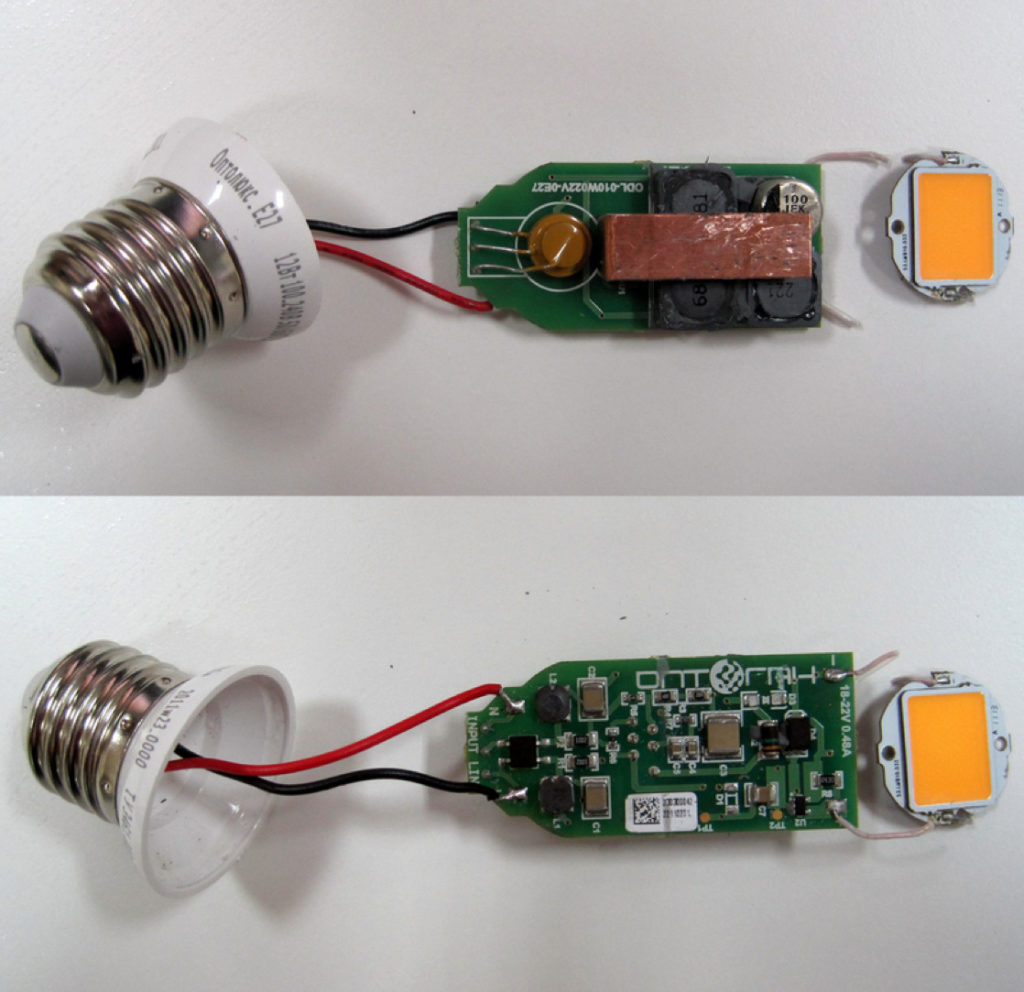

It is recommended to make a case for a DIY LED lamp only if the master has enough experience. In most cases, a part of the design is taken from an energy-saving lamp or incandescent. The burnt out light bulb should be disassembled and the conversion board removed. The schema is installed in one of the following ways:

- Hide in the plinth. A plastic bottle cap will do.

- Place the diodes in the holes made under the bulb in the lid.

- Arrange the circuits inside the plinth. This option is characterized by increased heat transfer characteristics. Here, the chips are connected through the existing holes.

To place the chips, it is enough to cut a circle out of thick cardboard or plastic. If you do the job carefully, the device will have an aesthetic appearance.

Base with incandescent lamps

Some craftsmen choose a base from an incandescent lamp to install the circuit, as it has an important advantage: after assembly, the master will not have difficulty screwing the light bulb into the cartridge, which will ensure heat transfer.

The base from the incandescent lamp is also characterized by its disadvantages. In the finished form, the design will not have a beautiful appearance, and it will also not be possible to make high-quality insulation.

We advise you to watch the video: How to assemble an LED (LED) lamp with your own hands.

Conclusion

Self-assembly of the LED lamp should begin with the choice of housing. Next, choose a scheme depending on the type of lamp and purpose. In order to gain experience, it is better for a novice master to start by replacing burned-out LEDs - this will provide an opportunity to get acquainted with the design and principle of operation of a light bulb.