How to replace a headlight bulb

So, the headlight of the car went out and it became “one-eyed”. If the installation of lighting elements was carried out in a car service, and the lamp is still far from the expiration date, then under the warranty agreement it must be changed free of charge. But not every car owner, because of such a trifle, is ready to be left without a vehicle for several days, as is the case with a long queue for service, so it’s easier to replace the light bulb yourself.

Fortunately, this process in most cases is not difficult, although it is not without some nuances. They need to be analyzed in more detail.

Briefly about the service life of the head optics

In principle, any automotive light source has a certain operating life, measured in hours, for example:

- for halogens - 600–800 hours;

- for xenons - 2000–2500 hours;

- for LED - up to 20,000 hours.

At the same time, it should be borne in mind that 2/3 of the time most drivers drive in the low beam, consuming the resource of this particular component.

Therefore, if, according to rough estimates, the lamp has already “run through” the period measured by the manufacturer, then most likely it is time to replace the low beam lamp without really bothering with diagnosing the causes.

We recommend to read: What is the penalty for driving with a non-working low beam headlight

What do you need to replace

The main suspect in the malfunction is the lamp. There are two approaches to check its performance;

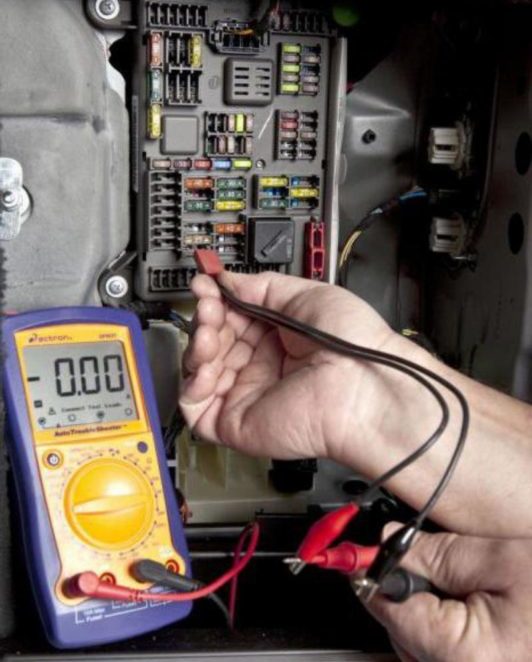

- Disconnect the terminal block, turn on the light on the instrument panel and check with a tester for voltage on the contacts.

- Check with a multimeter the contacts of the light bulb itself for an open circuit (not suitable for gas-discharge xenon lamps).

- Change the broken element to the adjacent one, on the opposite side to differentiate the breakdown.

If the lamp is working, then you will have to check the entire electrical circuit going to the headlight, starting with the safety block.

You can also evaluate the condition of the light bulb visually.

The risk of both options increases if you leave sweat marks on the glass during installation. In the contaminated area, the heat sink is disturbed, as a result of which either the tungsten filament burns out or the glass melts. That is why it is not recommended to touch the flask with your hands.

This happens when the ignition unit malfunctions, when an arc discharge occurs inside the bulb.

A burnt-out LED light source does not outwardly betray itself, and it will not work to check it with a multimeter without disassembly.

When there is no doubt about the source of the malfunction, it's time to replace the lamp with a new one. For this you will need:

- rubber or cotton gloves;

- screwdriver;

- new light bulb, identical in parameters to the original.

Gloves will have to be put on before opening the box with a new device in order to avoid accidental touching of the glass flask with your hands. For LED light sources, this rule is not necessary.

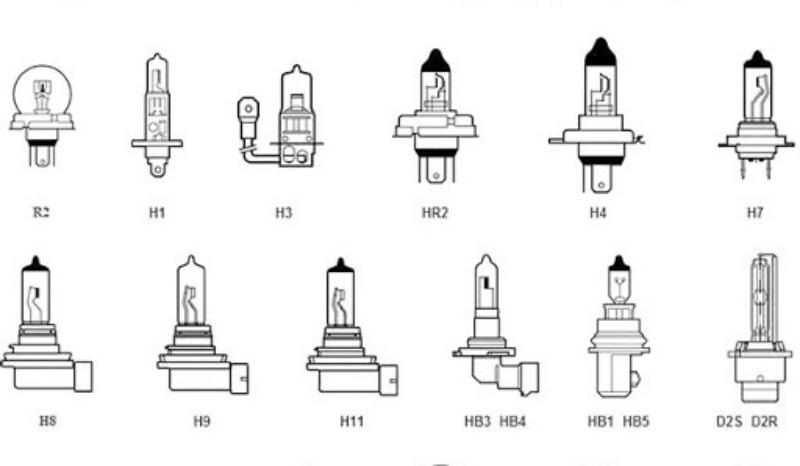

How to choose the right lamp

It is important that the light source corresponds to the technical documentation of a particular vehicle, since the installation of a more powerful or weaker device can damage the electronic control unit for vehicle systems. To select the right model, you can remove the broken light source and take it with you to the auto supply store. Consultants will help you deal with labeling and pick up replacement with the appropriate base and power, although this is easy to figure out for yourself.

Read also: Types, marking and purpose of car lamp bases.

How to properly remove the headlight bulb

First of all, you will have to open the hood and install it on the support bar. Removing the entire headlight assembly is not necessary in most cases. In some cases, the process for replacing the left and right low beam lamps may differ. For example, on the Volkswagen Golf 4 series, owners of large hands will have to remove the battery first, as it makes it difficult to access the left headlight unit.

On some models, this may concern the pipes and even the fan on the radiator. Before disconnecting electrical connectors it is recommended to disconnect one of the contacts of the power cable on the battery to avoid damage to the onboard control systems.

We remove protection

When access to the engine compartment and headlight is provided, the dismantling of the lamp, depending on the model, occurs in the following order:

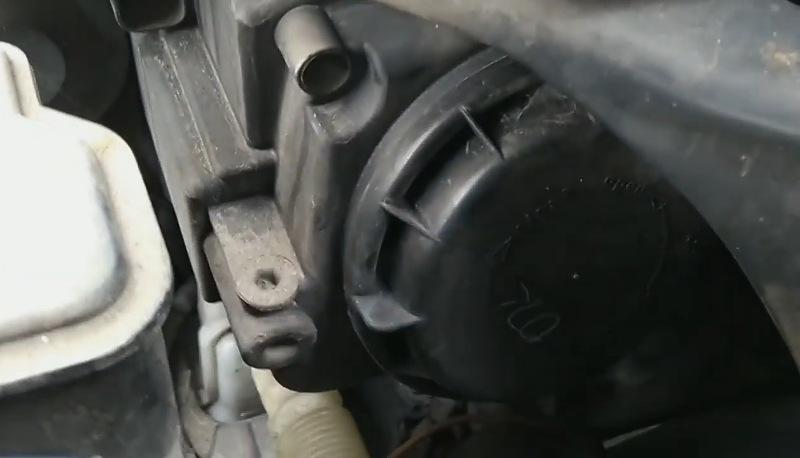

- The sealing cover is removed, which can be on the latch.Press with a finger or a screwdriver.If threaded, remove by turning counterclockwise.

- In systems without a cover, its function is performed by a rubber casing.If it is, you will first have to disconnect the terminal block from the lamp.Then remove the protective cover by pulling it by the edges or special straps.In xenon lamps, the contact block is most often a single unit with the ignition unit.

These elements are detached if they are pulled at a right angle.

We take out the lamp

When access to the internal structure of the headlight was gained, the stage of dismantling the light bulb came, the fastening of which can be of three types:

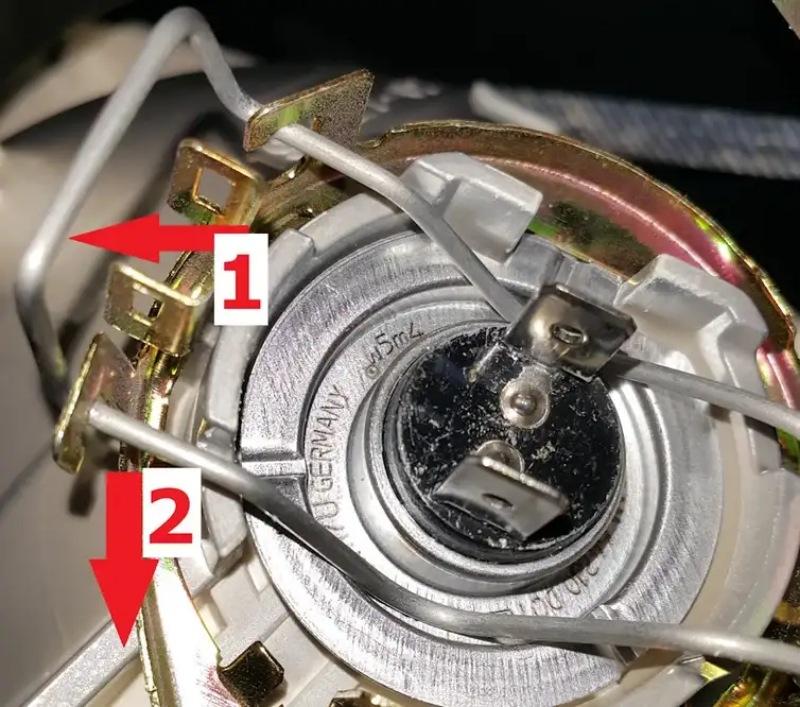

- Clamping spring.In this case, the spring retainer must be disengaged by pressing on the wire and pulling it to the side.

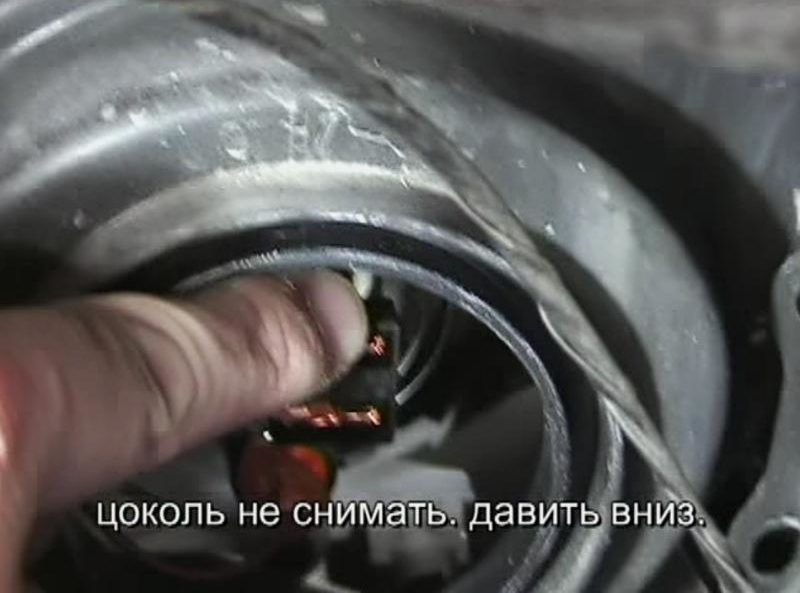

- On a latch located on top in the landing slot.The lamp is removed by sequentially pressing the base down with your finger and then pulling it up.

- On swivel brackets. The base is removed from the latches by turning the bulb counterclockwise by 15 °.After removing the lamp from the latches, it must be removed from the socket.

If the manual for the vehicle does not contain a guide to replacing light sources, then a phone with a camera and a flash will come in handy to help determine the type of mount.You will have to point the camera at the attachment point and take a few pictures or a video recording on which you can disassemble the fasteners.

Proper bulb replacement

If there is an adapter on the lamp base, then it must be disconnected and connected to a new device.

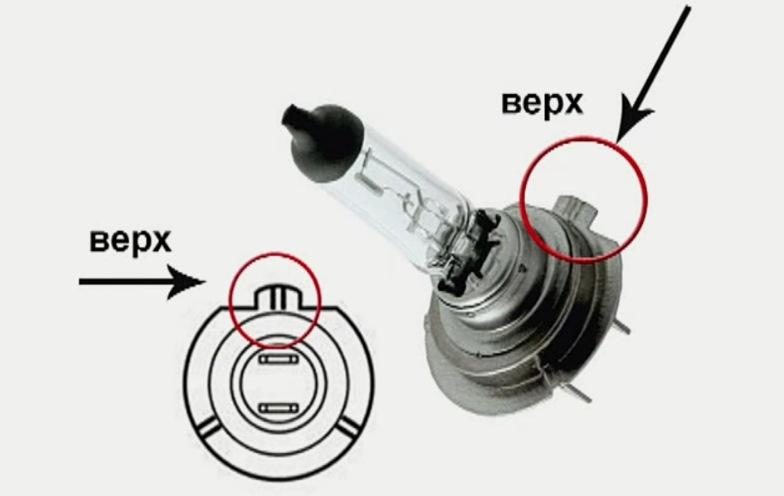

For plinths H4, H7, H19, special protrusions are arranged in such a way that they can only be placed in one position. Structural grooves in the headlight will not allow you to place the lamp on the wrong side. Subsequent assembly occurs in the reverse order:

- With hands in clean gloves, without touching the glass bulb with your fingers, the light bulb is placed in the seat with the ears in the structural grooves. At the same time, it is sometimes more convenient to install a light bulb by visually controlling the process from the front, through the glass of the headlight.

- A protective cover is put on.

- The contact block is connected.

- With an appropriate design, the headlight unit is closed with a lid.

After carrying out the manipulations, you need to connect the power cable to the battery contacts and check the performance of the new lighting elements.

If the flask turned out to be accidentally contaminated, then before installation it must be thoroughly wiped with alcohol and dried with a dry cloth.

What are the mistakes when replacing

Although the design of most bases does not provide for the possibility of installing a headlight lamp in different positions, some owners manage to push the bulb upside down, or even sideways. This happens most often with the H1 base, which does not have special protrusions for the grooves in the seat.

Although sometimes this happens with the H7 base.

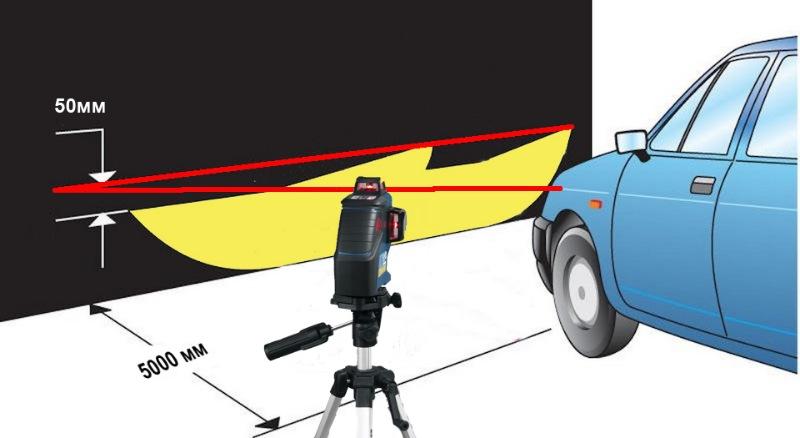

In this case, the low beam will shine upwards, which is clearly visible if you put the car in front of the garage door and turn on the headlights. On a flat surface, incorrectly installed lamps will form a spot of light with the right tick down, not up, in accordance with the rules.

A correctly installed halogen will be spiraled upwards: it is in this position that the rays are reflected from the reflector down onto the roadway in front of the car.

The second common problem is an attempt to install lighting elements not provided by the manufacturer. For example, on some cars, the installation of more economical LEDs of the same power as the standard halogen will cause the on-board computer to issue a headlight malfunction notification and limit the vehicle's speed.

The third mistake is chasing brightness and white. This is especially important for the northern regions, since white light with a temperature of 5000 Kelvin does not penetrate fog, dust and rain well. Although 3200K yellow is considered outdated and inconvenient, it is this spectrum that does the best job of illuminating the roadway in bad weather conditions. For the same reason, searchlights of rescue services are not made with white or blue light, which is so beloved by car owners for a clear outline and great brightness.

Video selection of replacement by car models.

Renault Duster.

Volkswagen Polo.

Skoda Rapid.

Hyundai Solaris.

Lada Grant.