How to properly connect a neon ribbon

Flexible neon has become widespread relatively recently. Now it is actively used in various fields, replacing conventional neon lamps. Flexible elements are easy to install, practically maintenance-free, and they are superior in power to LED strips.

What is flexible neon

Flexible neon 220V is a string of LEDs connected in series, placed in a durable matte tube. With the help of such devices, you can organize the backlight or create various inscriptions and drawings. Composed of:

- A flexible shell made of silicone or polymeric materials, which effectively protects the internal elements from impacts and forms the necessary glow shade.

- LEDs. Luminous devices of small size that convert incoming electricity into bright light.

- Wiring. Connects the diodes to each other and supplies voltage.

Varieties

There are several types of elements:

- Classic designs.The most popular models used by a large number of consumers.

- Professional. They are durable and are used by designers to create lighting.

- Low voltage. There are models for 24 and 12 V. They are used in low-voltage equipment.

To create advertising structures, elements of small thickness with bright colors are best suited. The exterior design is implemented using traditional neon with a round section. Devices are capable to serve more than 10 years even in the most difficult conditions.

On the market you can find flexible economy class neon. The elements use low-quality LEDs, so you should not count on long-term operation.

Neon for 220 V is characterized by an even glow without flickering, flexibility, increased reliability of the protective layer. The elements are resistant to mechanical stress, excessive dust and high humidity.

Flexible neon RGB deserves special consideration. A feature of this lighting is the ability to adjust the color at any time. Control is carried out using controllers that can be built into the circuit or have a remote signaling unit.

In addition to a constant color, you can turn on the mode of smooth flow of one shade to another. Processes are controlled by algorithms built into the system.

RGB elements are actively used to illuminate buildings, parks, advertising structures, interiors and cars. With their help, you can organize amazing stage scenery, which is actively used by theaters and concert halls.

White flexible cords are distinguished into a separate group. They are as simple as possible in design and can be used to highlight objects.With their help, you can easily emphasize the relief of ceilings, indicate an emergency situation on the road.

Models that emit white light are able to function for a long time, practically without changing their characteristics.

Applications

Most often, neon LED cords are used in the following areas:

- Refinement of car design. Neon is mounted both inside the cabin and on the body.

- Illumination of parks, squares and yards.

- Organization of illumination of pools and fountains.

- Decoration of buildings, lighting of the local area.

- Advertising banners, signs and posters.

- Road signs.

- Design of clubs, restaurants, bars and other public places.

Now even private owners of houses or apartments are striving to equip their interiors with lighting systems. You can find flexible neon even as an element of clothing.

Connection and installation of neon tape

Connecting flexible neon can be done by anyone after carefully studying the instructions.

Flexible neon is connected to a 220 V network through an adapter. It is advisable to use only original components from well-known manufacturers, so that in the future there will be no problems using the backlight. When working, it is important to observe safety precautions.

Fancy neon led strip

How to cut flexible neon

A feature of flexible neon is the possibility of cutting. To do this, manufacturers put marks on the cable along which the cut should be made. You don't have to solder or reconnect anything.

When assembling the chain, sealant is applied between the elements. The design will be ready for work after it dries.

Wiring diagram

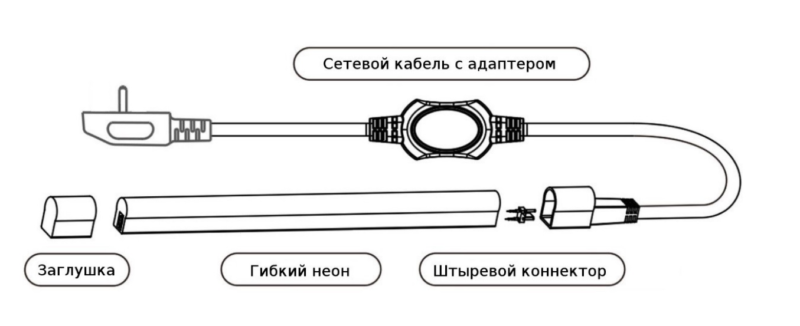

The connection diagram consists of the elements:

- flexible neon of the required power and shade;

- network cable with adapter;

- pin type connector for a secure connection;

- chain protectors.

There may be other elements that somehow affect the functionality of the backlight and its performance.

How to connect and fasten

Fastening of flexible neon is realized with the help of holders, profiles or brackets. Some methods are suitable for creating curved systems, while others provide reliable rectilinear fixation. The choice of technique depends on what kind of design you want to get as a result.

Straight installation

For a straight-line installation of flexible neon, you will need to purchase or make a guide profile. The profiles are fixed to the surface with screws with a pitch of 25 cm.

They are made of different materials: polymer, stainless alloys with minimal conductivity.

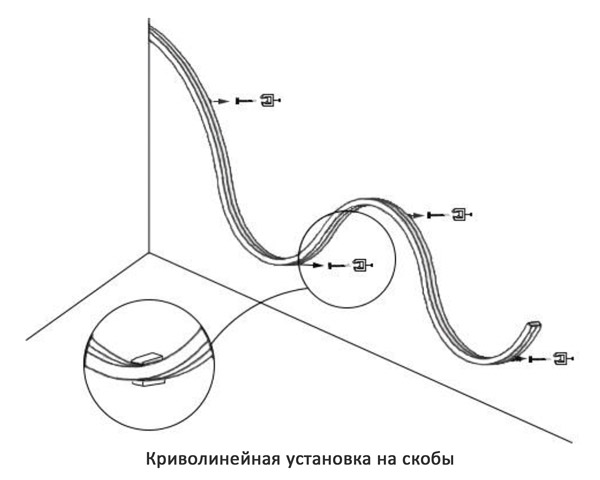

Curvilinear installation

Curvilinear installation is carried out using brackets or in a pre-calculated groove sealed with sealant. Staples on the surface are best fixed with screws or self-tapping screws.

Sealant or silicone in the second case should be as neutral as possible so that the surface of the tubes does not change its properties during operation.

Safety and Operation Rules

When installing flexible neon, the following rules must be observed:

- Turn off the power completely before installing the element.

- Before applying voltage to the circuit, make sure the system is tight and there are no exposed wires.

- Installation or repair of flexible neon is carried out only after reading the instructions.

- If a particular model is not designed for high humidity, it must be protected from exposure to water.

- Modern neon illuminators can operate at temperatures from -10 to +40 degrees Celsius.

- During installation, minimize mechanical impacts on the structure. Neon should not be bent, twisted or deformed in any way.

- To check, neon wound on a coil can be connected to the network for no more than 1 minute. Otherwise, overheating or a short circuit may occur.

- The basis for a flexible design should be a rigid surface.

- It is not recommended to hang an additional load on the structure in the form of signs or objects.

If the neon wire gets wet or dirty during transportation or preparation, it must be thoroughly cleaned and dried before installation.

During the assembly process, it is advisable to use only original cables and connecting connectors. Most often they are supplied assembled, however, compatible elements can be ordered additionally.

Maximum 50 meters of flexible neon can be connected to the network. In this case, the power will be evenly distributed over the diodes, which will ensure the correct operation of the equipment.

Sealing requires a quality and neutral sealant that is compatible with PVC materials and silicones.

During operation, it is forbidden to cover the running wiring. It is also not recommended to install the backlight in a closed space or place the tubes too close to each other. Safe use of the system requires constant air circulation.

Advantages and disadvantages

Flexible neon, like other devices, has advantages and disadvantages. Professional linear illuminators bending in any direction are considered to be of the highest quality.

The main advantages of the elements:

- uniform glow along the entire length;

- high brightness;

- a scattering angle of 360 degrees for round tubes and 180 degrees for rectangular ones;

- the use of different types of decor;

- a large selection of tube sections;

- the ability to cut into separate sections;

- high-quality protection against dust and moisture allows you to use the tubes even under water;

- convenient carrying;

- simple installation;

- flexible design allows you to create any shapes or patterns;

- resistance to mechanical stress, shock and vibration;

- minimal risk of short circuit;

- ecological purity of materials;

- cold neon does not emit ultraviolet radiation, which adversely affects a person;

- relatively low power consumption;

- great resource;

- nice appearance.

Unfortunately, there are some downsides:

- a significant amount of dust settles on the surface of the tubes and for high-quality use it is recommended to carry out regular cleaning;

- lack of power does not allow the use of flexible neon as the main source of illumination.