Headlight protection varnish after polishing

Headlight lacquer performs many functions, ranging from visual decoration to protection of lampshades. You can apply it with your own hands, but first you need to study the main varieties, popular manufacturers and safety rules when performing work.

Types of protective coatings for headlights

The composition is classified according to the material on which it can be applied. There are for glass, and there are for polymers, acrylic and polycarbonate. Also presented are different options in the form of release: aerosols and separate two components that are mixed before application.

There are 3 options available in auto shops:

- Acrylic one-component. There are both colorless and tinted models to choose from. It is produced in the form of a spray, you can apply it easily on your own, the composition dries quickly. When the varnish dries, its surface acquires a glossy sheen. The disadvantage of the acrylic one-component composition is that it does not fit well into cracks and chips, therefore it is not entirely suitable for covering polycarbonate.Acrylic composition from the company KUDO.

- Two-component. Two components are poured into different containers, one of them contains a varnish, the other contains an additive for hardening. Before coating the headlights, both compounds are mixed. According to the application process, working with a two-component varnish is a little more complicated, but it allows you to achieve a better result. The substance covers the entire surface, so it can be used to coat plastic parts.Two components before mixing.

- Urethane. Produced in the form of an aerosol, completely transparent. Proper application of urethane varnish requires thorough surface preparation, including cleaning and degreasing. It will create a good protective layer, will prevent mechanical and atmospheric effects on the headlights.Aerosol with urethane composition.

Varnishes can be transparent and tinted. The former perform mainly protective functions, the latter allow you to improve the appearance of the car.

Varnishes that are applied to the headlights after polishing are also classified according to their hardness characteristics. They depend on the percentage of the polymer fraction:

- HS. The abbreviation denotes compositions with a large volume of dry matter and a minimum amount of solvent. Externally characterized by a bright sheen. To enhance the protective functions can be applied in one and a half layers.

- MS. Formulations with an average amount of dry matter and solvent. They are applied to the headlights in several layers (usually 2-3), while each new layer is applied only after drying.

- USH. Formulations with the highest dry matter content. Thanks to this, the composition dries quickly and becomes as durable as possible.

Why varnish is needed, its functions

Earlier in the automotive industry, glass was used for headlights.The disadvantage of this material is the fragility and sharpness of the fragments, which in emergency situations carried an additional danger. Now everyone has switched to plastic, it's cheaper, more reliable, safer.

But plastic also has its drawbacks. Even a small pebble can leave a noticeable scratch on the surface. The sun also acts as a pest, under the influence of the rays of which the material darkens, turns yellow and loses its external attractiveness.

Polishing is responsible for restoring the appearance. Its essence is that the upper damaged layer is removed, leaving a clean headlight, it looks like new. To prevent the material from becoming unusable again, the polished headlight is varnished, this allows you to provide the following functions:

- reduce the intensity of wear of the shades;

- create an additional layer to protect against mechanical stress, sunlight, precipitation;

- improve appearance due to the formation of a glossy sheen;

- facilitate cleaning, because dust and dirt are easily removed from the varnished surface.

By improving the protective properties lights will last longer, and this will entail cost savings on the replacement of these parts.

Review of the best polishes for headlights after polishing

Varnishing the headlights after the next polishing is the right solution to improve the protective properties. It remains only to choose among the options available on the market.

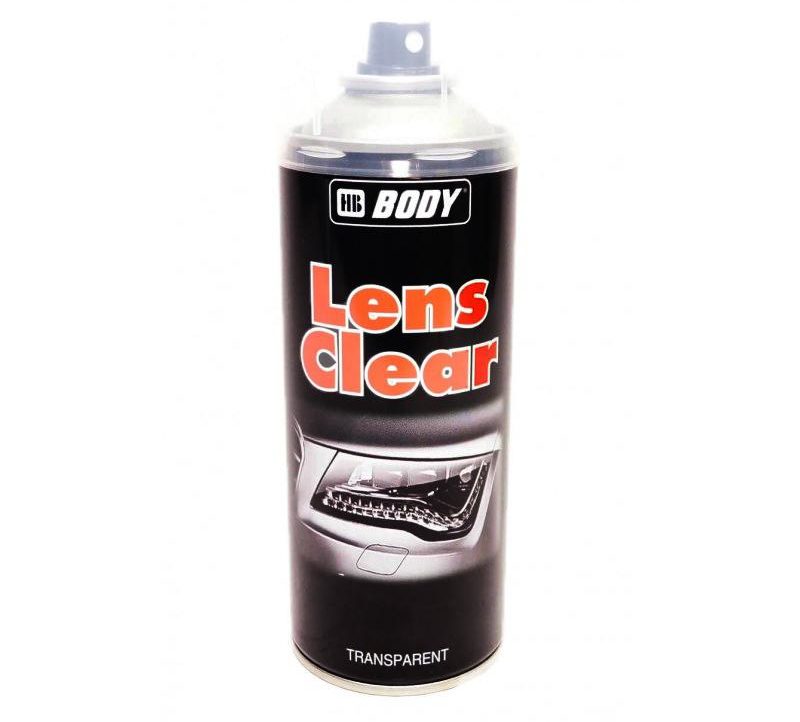

lens clear

The world-famous Greek company HD Body has in its assortment a good product for varnishing headlights. It is produced in the form of an aerosol, has elastic properties, dries quickly after application. Provides a good level of protection from sunlight and mechanical stress.

Infinity

This two-component version is already from the American company Delta Kits, and it is approved for use in the Clear Pro Plus repair system. The composition has absolute transparency and glossy shine, so the headlights will look like new. Additionally, transparency and brilliance increase the brightness of the lamp illumination.

Spot On

Where in this area without the products of the famous Japanese company Kovax. Its varnish has a transparent structure, restores the appearance of ceiling lamps, increases brightness, levels out minor damage and yellowness. Includes 3 components at once, sold as a set.

Rules for varnishing the headlight after polishing

The process of coating headlight shades with varnish is simple, but if you make mistakes in it, the result may not be at all what you expected. There are some nuances at different stages of the work, and they may depend on the type of varnish chosen:

- The first mandatory step is cleaning. Any dirt and dust can harm the future coating. Even more dangerous is the remnants of bituminous sealant, this substance significantly impairs adhesion. It is necessary to clean the headlights, remove all remnants of materials, dirt, cover with a degreasing agent. It is also important that the surface is completely dry, for this it must be left for several hours.

- Dilution of a two-component varnish. According to the instructions, the composition must be diluted immediately before application. It is better to do this in batches in order to dilute as much material as is used in the next 10-15 minutes, after this time the composition loses its properties.

- Coating before applying acrylic lacquer.If this option is chosen, you should not use special pastes for polishing, because they will impair the adhesion of materials.Acrylic lacquer does not adhere well to paste.

- Time to get strength. After applying the varnish, he needs 24 hours to "take root" and be ready for use. During this time, it is forbidden to use the car, wash the headlights, polish their surface.

- The use of formulations in cans. The application is made from a distance of 10-15 centimeters, the jet should move perpendicular to the plane of the ceiling. Each next line should cover half of the previous one.

- If the coating is carried out by a non-removable method (the headlights remain in the car), then the parts of the body adjacent to them must be sealed so that the composition does not accidentally get on them.Protection of surrounding body parts.

- To avoid the formation of stripes, the application is carried out in stages with a change in the direction of movement.

- To speed up drying, you can briefly turn on the headlight after application or use a hot air dryer.

The surface structure of the headlights can be affected by errors made in polishing process. It is important to gradually change the grain size of the materials and prevent overheating of the surface when working with a grinder.

Safety

When performing work, it is important not only to do everything according to the instructions, but also to adhere to safety rules:

- When applying varnish, protective clothing is used. Gloves, goggles are required, protective overalls will also be useful. Additionally, it is worth taking care of the respiratory tract, paintwork materials can only be applied in a respirator.

- Room preparation. The work area must be clean and well ventilated.

- Fire safety. There should not be any sources of open flame near the headlights. It is advisable to have a fire extinguisher on hand.

- Avoidance of strangers. It is important that children do not have access to the place of work, it is also desirable to limit access to pets.

At the end of the thematic video.